Diseño de jefes: Elementos clave, directrices de diseño, problemas comunes y soluciones

Comprender el diseño de patrones en el moldeo por inyección, centrándose en los elementos clave, las directrices de diseño y las soluciones de piezas moldeadas de plástico.

Estrategias para diseñar con éxito productos con los materiales adecuados

Hablemos del papel de la selección de materiales en el diseño de productos, centrándonos en la colaboración con los moldeadores para obtener productos estéticamente agradables.

Dominar los agujeros ciegos y pasantes en el diseño

Explore los agujeros ciegos y los agujeros pasantes en esta guía dirigida específicamente a profesionales que deseen mejorar sus habilidades en el diseño de piezas.

Pasos generales en el diseño de productos sanitarios y el desarrollo de productos

Descubra las etapas clave del diseño de dispositivos médicos y el desarrollo de productos, garantizando la calidad y el cumplimiento de estrictas normativas.

Factores que afectan al coste o precio del prototipo

Descubra los factores clave que afectan a los costes de los prototipos rápidos. Una guía concisa para entender y estimar los precios de los prototipos rápidos.

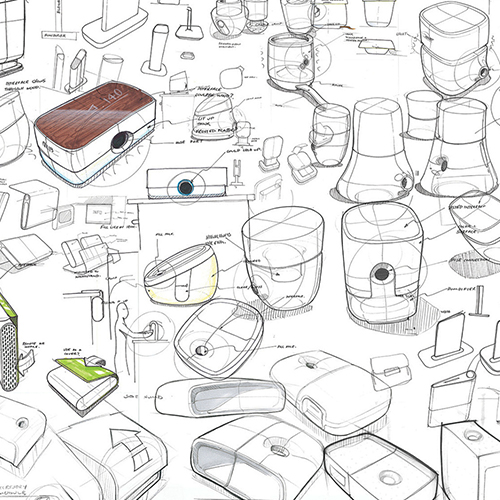

El ABC del diseño de estilo de producto En el diseño industrial

Explore el mundo de la estilización de productos en el diseño industrial. Da lugar a productos únicos, funcionales y estéticamente atractivos.

Como principiante, ¿qué software de diseño de productos debo elegir?

Compare el software de diseño de productos, desde CAID y Rhino hasta CATIA y SolidWorks, y sus funciones únicas en el diseño estético y estructural.

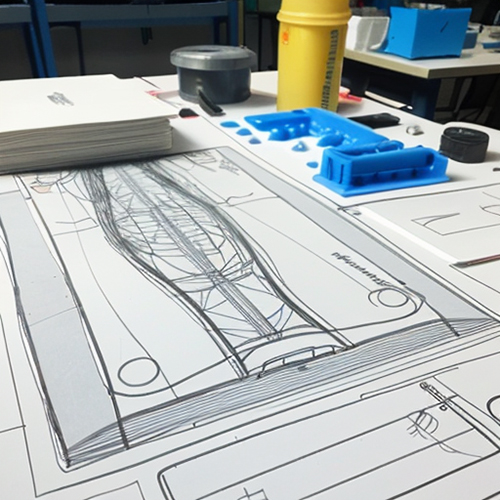

Principios generales del diseño de piezas de plástico para moldeo por inyección

Experienced product designers deeply understand injection molding processes and consider numerous factors in plastic part design. This article focuses on essential elements such as wall thickness, draft angles, ribs, holes, pillars, snaps, interference fits, and tolerances in plastic molded part design. Wall Thickness In Plastic Parts Design Determining the appropriate wall thickness is crucial. Other […]

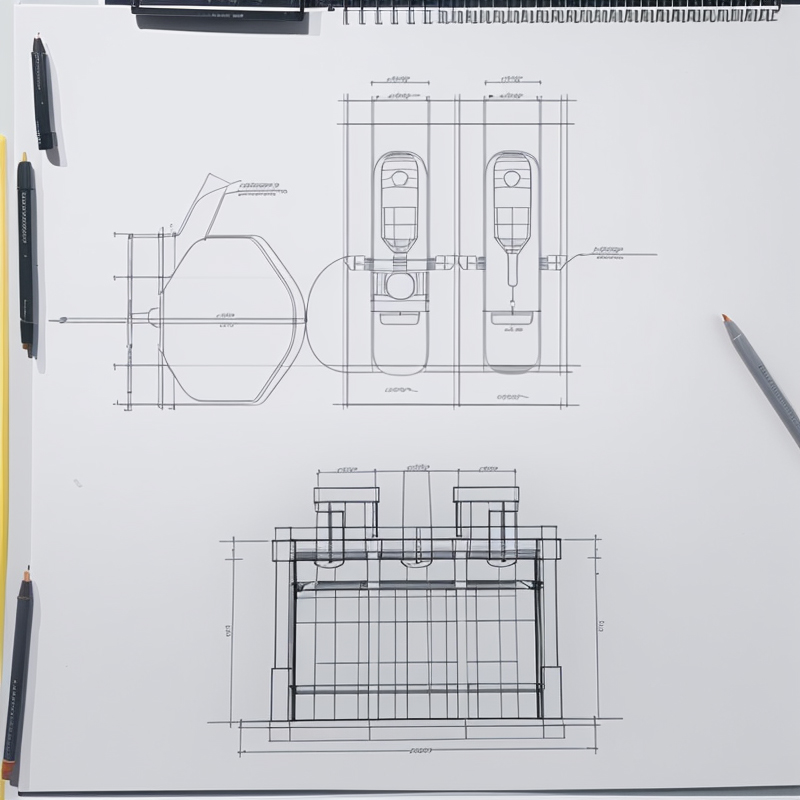

¿Qué fundamentos son necesarios para un excelente diseño estructural de productos?

Product structural design refers to the process of designing the physical aspects of products, such as digital devices and home appliances, after their external appearance has been conceptualized. How to understand the definition of “Product Structural Design” This design phase bridges the gap between the aesthetic design and the manufacturing process. For instance, in the […]

Pasos para desarrollar un producto de éxito

Pasos para desarrollar con éxito un producto, desde la generación de la idea hasta la evaluación posterior al lanzamiento, adaptados a empresarios y gestores de productos.