Puesta a punto de sus proyectos CNC: Guía para el mecanizado de acabado

El acabado superficial o mecanizado de acabado, un aspecto crítico del mecanizado, profundiza en los detalles finos del perfeccionamiento de la calidad externa y la funcionalidad de una pieza de trabajo. Este preciso proceso implica un meticuloso ajuste de la superficie, ya sea por eliminación o adición de material, para cumplir los más altos estándares de aspecto y rendimiento. Si ya conoce los fundamentos del acabado [...]

Optimización de la producción con el semiacabado en el mecanizado

La industria manufacturera valora mucho el papel del semiacabado. Este proceso crucial consiste en refinar un producto hasta un nivel específico de acabado antes de llegar a la fase de acabado final. Es fundamental para garantizar que el producto final cumpla las especificaciones y normas requeridas, mejorando la calidad y la estética. Diversas industrias, desde piezas de automoción hasta componentes aeroespaciales y [...]

Del bruto al refinado: Exploración de los métodos de mecanizado en bruto

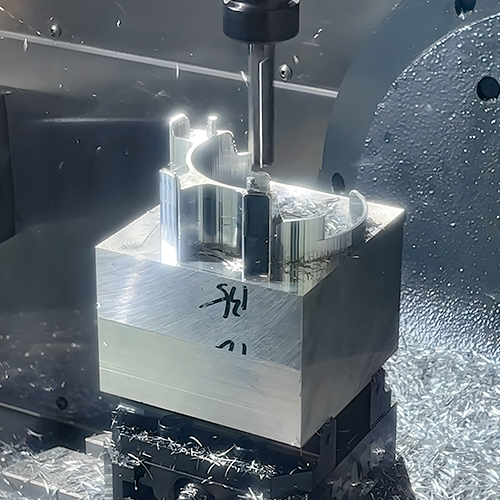

El mecanizado de desbaste es un proceso que consiste en eliminar rápida y eficazmente el exceso de material para acercar la pieza a su diseño final. Este enfoque de mecanizado CNC emplea herramientas de corte más grandes, realizando cortes amplios y potentes para eliminar rápidamente cualquier material no deseado de una pieza de trabajo. El resultado puede ser un acabado superficial más basto, pero [...]

Fabricación cerámica: Qué es, el proceso y consideraciones clave

La fabricación de cerámica es un proceso complejo y fascinante que implica el uso de materiales y técnicas avanzadas para crear una amplia gama de productos, desde artículos para el hogar hasta componentes de alta tecnología para aplicaciones aeroespaciales y de defensa. Uno de los métodos más populares para la fabricación de cerámica es el moldeo por inyección, que permite crear formas y diseños complejos con [...].

Guía detallada sobre la puerta del moldeo por inyección

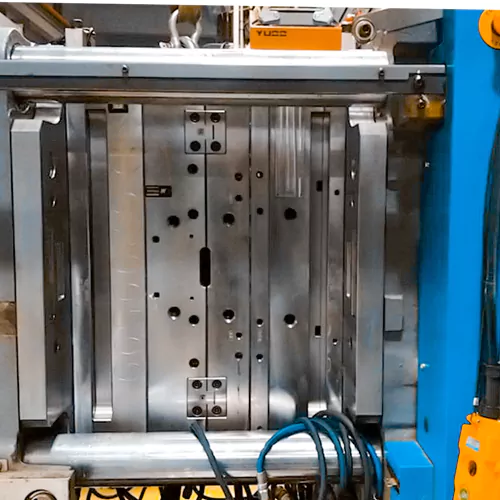

Aunque las herramientas de moldeo por inyección son difíciles de diseñar y fabricar, sus conceptos esenciales son sencillos de comprender. El molde consta de dos caras, una de las cuales tiene una cavidad y un núcleo en el que se inyecta el plástico. El plástico -que, como su nombre indica, se inyecta en el molde a través de un bebedero que alimenta [...]

Mecanizado por electroerosión: Comprensión del funcionamiento, características y componentes

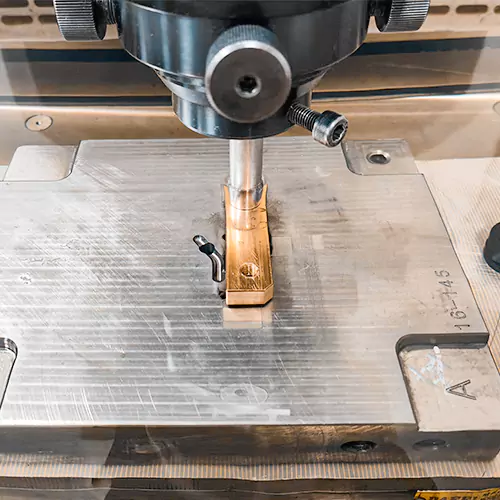

Los costes de utilizar métodos de producción estándar pueden dispararse si necesita dimensiones, materiales u otras especificaciones inusuales para su producto fabricado. El mecanizado de un bloque con aberturas y chaflanes para cojinetes o componentes requiere complicados procesos de fresado, torneado y taladrado. ¿Y si crea una o dos piezas para su prototipo cuando aún está en [...]

¿Cómo funciona la fabricación bajo demanda?

El término "fabricación" suele asociarse a plantas de producción y ensamblajes a gran escala con complicadas máquinas que producen continuamente diversos productos. Aunque este enfoque de fabricación es común y tradicional, un modelo de fabricación en rápido crecimiento está ganando popularidad, ya que resuelve varias de las limitaciones inherentes a la fabricación tradicional. Se trata de la fabricación bajo demanda. [...]

Introducción completa de las piezas de molde

El moldeo por inyección es principalmente un fenómeno de los procesos de fabricación del plástico. Es un proceso de fabricación que consiste en dar forma a una materia prima líquida o maleable con la ayuda de un armazón fijo, también conocido como molde o matriz. Un molde es un receptáculo de cavidad hueca, generalmente de metal, en el que se introduce líquido [...]

Cambio de troqueles en un solo minuto en la industria del automóvil

SMED o Single Minute Exchange of Die es el proceso de minimizar el tiempo de cambio o preparación. Implica identificar y eliminar cualquier aspecto innecesario del proceso de transición. Cuando es necesario sustituir una pieza de un equipo industrial, el tiempo de inactividad puede ser costoso e inesperado. El SMED es esencial para la fabricación ajustada, ya que puede eliminar [...]

Moldes Para Inyección De Plástico: La Guía Más Básica

Para la fabricación de piezas de plástico pequeñas, medianas y grandes, la técnica de fabricación más utilizada son los moldes para inyección de plástico. En el procedimiento se utiliza una máquina de moldeo por inyección, plástico sin procesar y un molde. Tras calentar el plástico fundido en la máquina, éste se inyecta en la cavidad, donde se [...]