CNCプロジェクトの微調整:仕上げ加工ガイド

Surface finish or finish machining, a critical aspect of machining, delves into the fine details of perfecting a workpiece’s external quality and functionality. This precise process involves a meticulous surface adjustment, either by material removal or addition, to meet the highest standards of appearance and performance. If you’re already acquainted with the fundamentals of finishing machining, you’ll appreciate the importance of every detail. In this article, we’ll delve deeper into precision finishing machining, unraveling the nuances of this high-precision endeavor. We’ll explore the key considerations, benefits, functions, and pitfalls to avoid when striving for that exact and refined outcome. Whether you’re an industry professional or a budding enthusiast in precision […]

機械加工における中仕上げによる生産の最適化

The manufacturing industry highly values the role of semi-finishing. This crucial process involves refining a product to a specific level of completion before reaching the final finishing stage. It is pivotal in ensuring the end product meets the required specifications and standards, enhancing quality and aesthetics. Various industries, from automotive parts to aerospace components and medical devices, widely use semi-finishing. In this article, we will take a look at the intricacies of semi-finishing, its methods, and its pivotal role in delivering top-notch manufacturing outcomes. Join us in uncovering the essential aspects of this intermediate machining stage and its importance in the production process. Understanding the Mechanics of Semi-Finishing in Intermediate […]

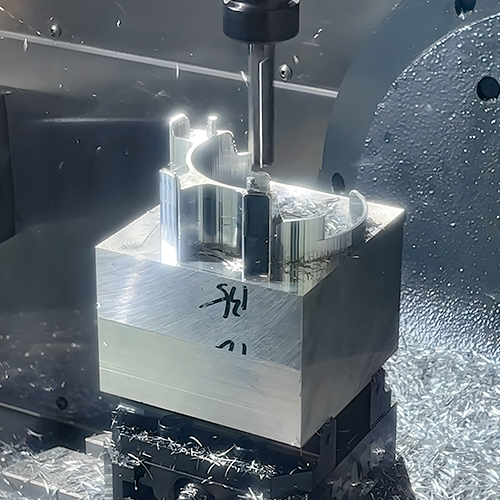

未加工から洗練へ:粗加工の方法を探る

Rough machining is a process that involves swiftly and efficiently eliminating excess material to bring your workpiece one step closer to its final design. This CNC machining approach employs larger cutting tools, making broad and powerful cuts to eliminate any unwanted material from a workpiece quickly. The result may be a coarser surface finish, but the goal is efficiency and speed. However, it’s much more than its name suggests; it’s the robust bridge between the raw material and the meticulous precision required in subsequent machining phases. In this article, we’ll talk about the important things to think about, the advantages, what rough machining does, and the usual errors people make […]

セラミック製造:セラミック製造とは何か、そのプロセス、主要な考慮事項

セラミック製造は複雑で魅力的なプロセスであり、高度な材料と技術を駆使して、家庭用品から航空宇宙・防衛用途のハイテク部品まで、さまざまな製品を作り出します。セラミック製造の最も一般的な方法のひとつが射出成形で、高い精度と再現性で複雑な形状やデザインを作り出すことができます。この記事では、射出成形プロセスを通じて、さまざまな製品を製造するためにセラミックがどのように使用されるかについて、順を追って説明します。セラミック材料の特性以下は、セラミック製造を標準的で非常に最適な製造ソリューションとする特性です:硬度:セラミックは丈夫で、摩耗や引き裂きに対して非常に耐性があります。[...]

射出成形ゲートに関する詳細ガイド

射出成形用金型は設計も製造も難しいが、その本質的な概念は簡単に理解できる。金型は2つの面で構成され、一方の面にはキャビティとコアがあり、そこにプラスチックが射出される。プラスチックは、その名が示すように、ランナープラスチックを供給するスプルーを介して金型に注入され、ゲートを通って金型のキャビティに入る。射出成形のゲートは、キャビティ/コアへのプラスチックの文字通り入り口であり、金型を左右する。金型が小さすぎれば充填されず、大きすぎればプラスチックの充填が困難になる。

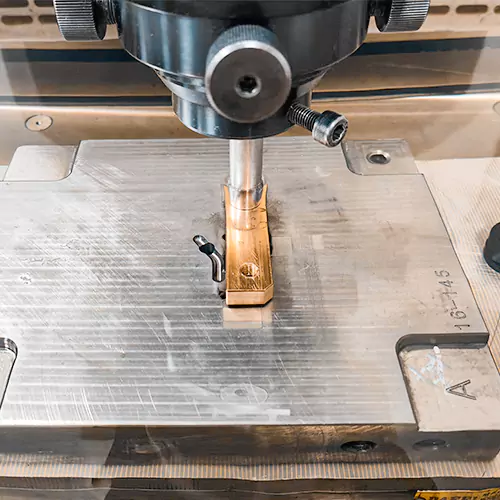

EDM加工:操作、特性、コンポーネントを理解する

製造する製品に特殊な寸法や素材、その他の仕様が必要な場合、標準的な製造方法を使用するとコストが高騰する可能性があります。ベアリングや部品保持用の開口部や面取りがあるブロックを加工するには、複雑なフライス加工、旋盤加工、穴あけ加工が必要です。企画や設計の段階で、プロトタイプ用の部品を1つか2つ作る場合はどうでしょう?放電加工のようなサービスは、フライス加工や旋盤加工のような伝統的な加工技術に代わる、時間と資源の効率的な方法かもしれません。この製造プロセスでは、誘電体浴液で隔てられた2つの電極間で連続する電流放電が、ワークピースから余分な材料を除去します。この包括的なガイドでは、我々は[...]を

オンデマンド製造の仕組み

製造業」という言葉は、複雑な機械が様々な商品を連続的に生産する大規模な製造工場や組立工場と結びつけられているのが一般的だ。このような製造アプローチは一般的で伝統的なものだが、従来の製造に内在するいくつかの制限を解決するため、急速に普及しつつある製造モデルがある。これはオンデマンド製造と呼ばれている。オンデマンド製造」とは何か?カスタム製造やクラウド製造とも呼ばれるオンデマンド製造は、必要なときに必要な量だけ製造する製造システムである。この新しい技術は、大量生産され、販売、流通、納品されるまで施設に保管される従来の製造とは異なる。[...]

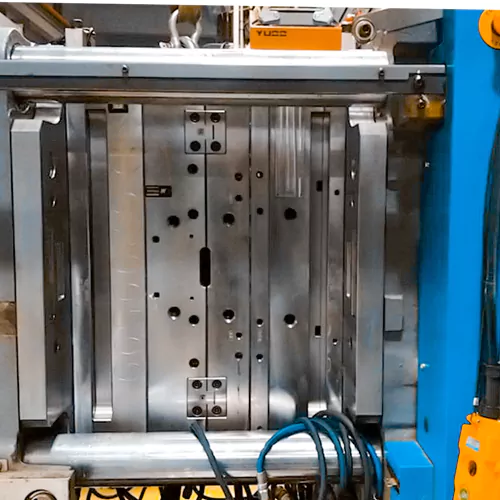

金型部品の完全な紹介

射出成形は、主にプラスチックの製造工程における現象である。これは、金型またはマトリックスとしても知られる固定枠の助けを借りて、液体または可鍛性の原料を成形する製造工程である。金型とは、通常は金属でできた中空の空洞の容器のことで、そこに液状のプラスチック、金属、セラミック、ガラスなどを流し込む。その他の金型部品は、プラスチックの製造工程で使用される。さまざまな成形プロセス プラスチックは合成物質であり、さまざまな成形技術によってあらゆる形状に成形することができる。これらの成形工程では、さまざまな金型部品が使用される。いずれの工程も、[...]を使って作業することを必要とする。

自動車産業における金型の1分間交換

SMED(Single Minute Exchange of Die)とは、金型交換や段取り替えの時間を最小限に抑えるプロセスです。これは、段取り替えプロセスにおいて不要な部分を特定し、排除することを意味します。産業機器の一部を交換する必要がある場合、ダウンタイムはコストがかかり、予期せぬ事態を招く可能性があります。SMEDは、無駄を省き、生産性を向上させ、コストを削減することができるため、リーン生産に不可欠である。しかし、この戦略を採用するには、単純なフルフォームの意味だけでなく、この戦略が何であり、何をもたらし、どのように提供するかについて、もっと多くのことがある。それでは、すべてを詳しく説明していこう。金型1分交換の基本:SMEDシステムは[...]です。

プラスチック射出成形用金型:最も基本的なガイド

小型、中型、大型のプラスチック部品の製造には、プラスチック射出成形用の金型が最もよく利用される製造技術である。射出成形機、未加工のプラスチック、そして金型がその手順で使用される。成形機で溶融プラスチックに加熱された後、プラスチックはキャビティに射出され、そこで冷えて固まり、完成品が形成される。自動車、医療、小型エンジン、配管、工業、農業など、ほぼすべての産業でプラスチック部品が使用されている。製造業者は、プラスチック射出成形用の最新金型を利用することで、超高品質のプラスチック部品を可能な限り速いスピードと高い精度で作ることができる。