Dominar la precisión: Una inmersión profunda en la inspección dimensional en el moldeo por inyección

El artículo se centra en la función clave de la inspección dimensional en el moldeo por inyección y analiza el uso de tipos de equipos para la medición.

¿Cuáles son las piezas moldeadas más comunes de los vehículos eléctricos?

Consulte la lista de piezas moldeadas habituales en vehículos eléctricos. Haga clic para saber cómo fabrican estos avanzados componentes las empresas de moldeo por inyección.

Tendencias del moldeo por inyección: Lo que hay que tener en cuenta en 2024

La industria del moldeo por inyección está en constante movimiento, adaptándose a las tecnologías emergentes, a la evolución de las demandas del mercado y a la creciente conciencia medioambiental. En este dinámico panorama de tendencias de la industria del moldeo por inyección, varios desarrollos clave en la industria del moldeo por inyección han tomado protagonismo. A medida que nos acercamos al umbral de 2024, es crucial seguir de cerca [...]

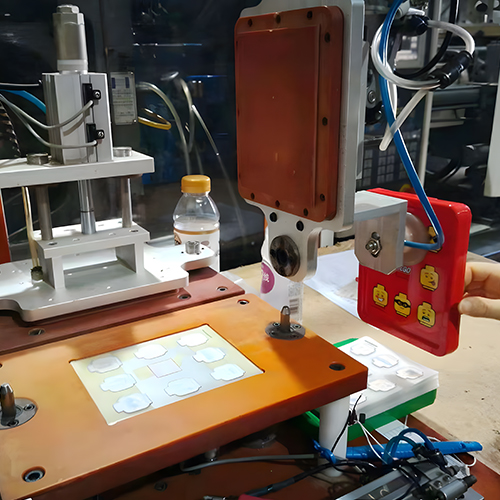

El proceso de etiquetado en molde

Explore el etiquetado en molde (IML) con Prototool: un cambio radical en la producción de envases por su durabilidad, calidad y eficacia.

Guía para la autodegradación en el moldeo por inyección

Explore la autodegradación en el moldeo: carreras de apertura del molde, su principio, ventajas de la compuerta de precisión, 3 consejos y comparaciones de acabado del molde.

6 formas de lograr rebajes en el moldeo por inyección

Sumérjase en la función del moldeo por inyección. Conozca su significado, domine 6 técnicas y afronte los retos habituales con eficacia.

Producción de componentes de auriculares mediante la técnica de moldeo por inyección 2K

Headphones often consist of multiple components, each with distinct color or material requirements. The two-shot injection molding technique has emerged as a game-changer in meeting these diverse needs. This advanced production method ensures that headphone components are not only aesthetically pleasing but also durable and of high quality.

Protocolos de seguridad en el taller de moldeo por inyección

Aprenda las normas de seguridad de moldeo por inyección en el taller. Una buena planta lidera con prácticas de primer nivel y prioriza la seguridad en todas las operaciones.

Normas y recomendaciones sobre tolerancias de moldeo por inyección

Explore las normas y las mejores prácticas para establecer tolerancias de moldeo por inyección. Profundice en los factores que afectan a las tolerancias y obtenga asesoramiento experto.

Tipos de técnicas de moldeo por inyección para electrodomésticos

Explore las seis técnicas fundamentales del moldeo por inyección de electrodomésticos y comprenda los entresijos que conforman el sector.