Maîtriser la précision : Une plongée en profondeur dans l'inspection dimensionnelle dans le moulage par injection

L'article se concentre sur la fonction clé de l'inspection dimensionnelle dans le moulage par injection et examine les types d'équipements utilisés pour les mesures.

Quelles sont les pièces moulées les plus courantes pour les véhicules électriques ?

Consultez la liste des pièces moulées les plus courantes pour les véhicules électriques. Cliquez pour savoir comment ces composants avancés sont fabriqués par les entreprises de moulage par injection.

Tendances du moulage par injection : Ce qu'il faut surveiller en 2024

L'industrie du moulage par injection est en mouvement constant, s'adaptant aux technologies émergentes, à l'évolution des demandes du marché et à une conscience environnementale croissante. Dans ce paysage dynamique des tendances de l'industrie du moulage par injection, plusieurs développements clés de l'industrie du moulage par injection ont pris le devant de la scène. Alors que nous approchons du seuil de 2024, il est crucial de garder un œil attentif sur [...]

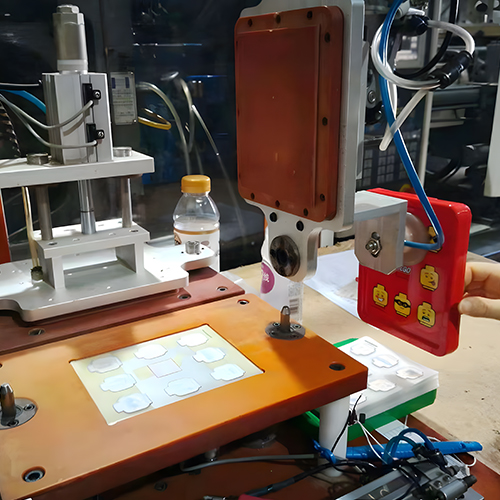

Le processus d'étiquetage dans le moule

Découvrez l'étiquetage dans le moule (IML) avec Prototool : un outil qui change la donne dans la production de conteneurs en termes de durabilité, de qualité et d'efficacité.

Guide de l'autodégradation dans le moulage par injection

Découvrez l'autodégradation dans le moulage : les courses d'ouverture du moule, son principe, les avantages de la porte de précision, 3 conseils et les comparaisons de finition des moules.

6 façons de réaliser des contre-dépouilles dans le moulage par injection

Plongez dans le rôle du moulage par injection. Apprenez leur signification, maîtrisez 6 techniques et relevez efficacement les défis courants.

Production de composants d'écouteurs par la technique de moulage par injection 2K

Les casques d'écoute sont souvent composés de plusieurs éléments, chacun ayant des exigences différentes en matière de couleur ou de matériau. La technique de moulage par injection en deux temps a changé la donne pour répondre à ces divers besoins. Cette méthode de production avancée garantit que les composants des écouteurs sont non seulement esthétiques, mais aussi durables et de haute qualité.

Protocoles de sécurité pour le moulage par injection Dans l'atelier

Apprenez les règles de sécurité du moulage par injection dans l'atelier. Une bonne usine adopte des pratiques de premier ordre et donne la priorité à la sécurité dans toutes ses activités.

Tolérances pour le moulage par injection - Normes et recommandations

Explorez les normes et les meilleures pratiques pour définir les tolérances de moulage par injection. Examinez les facteurs qui influencent les tolérances et obtenez des conseils d'experts.

Types de techniques de moulage par injection pour les appareils ménagers

Découvrez les six techniques essentielles du moulage par injection d'appareils électroménagers et comprenez les subtilités qui façonnent l'industrie.