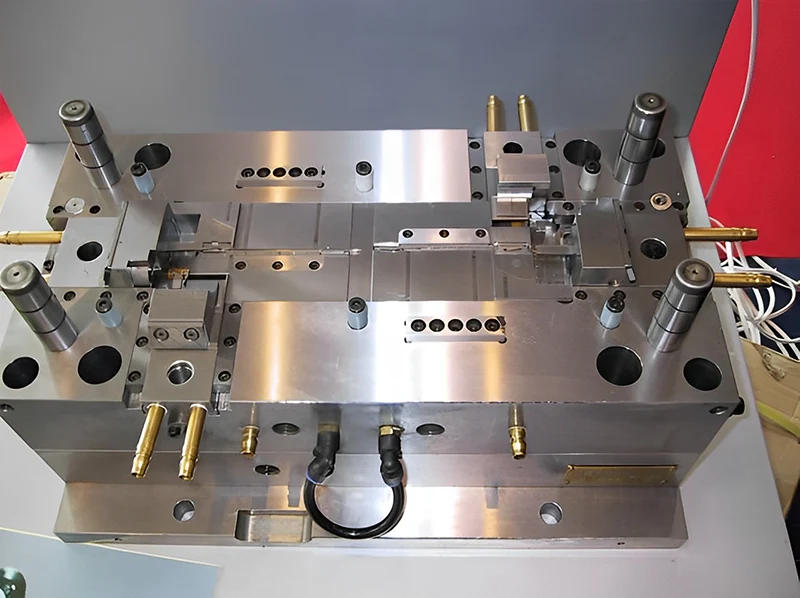

Molds are an essential part of making a lot of plastic items in the field of plastic manufacturing. Most of the time, these carefully made hollow forms are made of stainless steel. They are used as a base for injecting plastic material, which makes it possible to shape parts precisely as needed.

Among all the different kinds of molds, the multiple-cavity mold stands out as an advanced option, making it possible to create multiple parts simultaneously. This significantly improves production efficiency and output.

This article details multi-cavity molds, including how they are made, their benefits, and how they help improve plastic-making. By looking at the main factors affecting how accurate and reliable they are, we show the technical details that make multi-cavity molds a popular choice for high-volume production in many industries.

The Need for Multi-Cavity Molds:

A multiple-cavity mold has more than one space for the same part, and each production run makes more than one part. Utilizing a multi-impression mold speeds up the production of the desired quantity of parts, as it allows for quicker manufacturing of each batch. This approach increases productivity and yields a more favorable return rate for larger production runs.

You can also make better use of the injection molding cycle time and make more parts from the same mold within the shot promise with a mold with more than one cavité du moule. At Prototool, our multi-cavity molds ensure you get quality parts while keeping precise standards and maximizing cycle times.

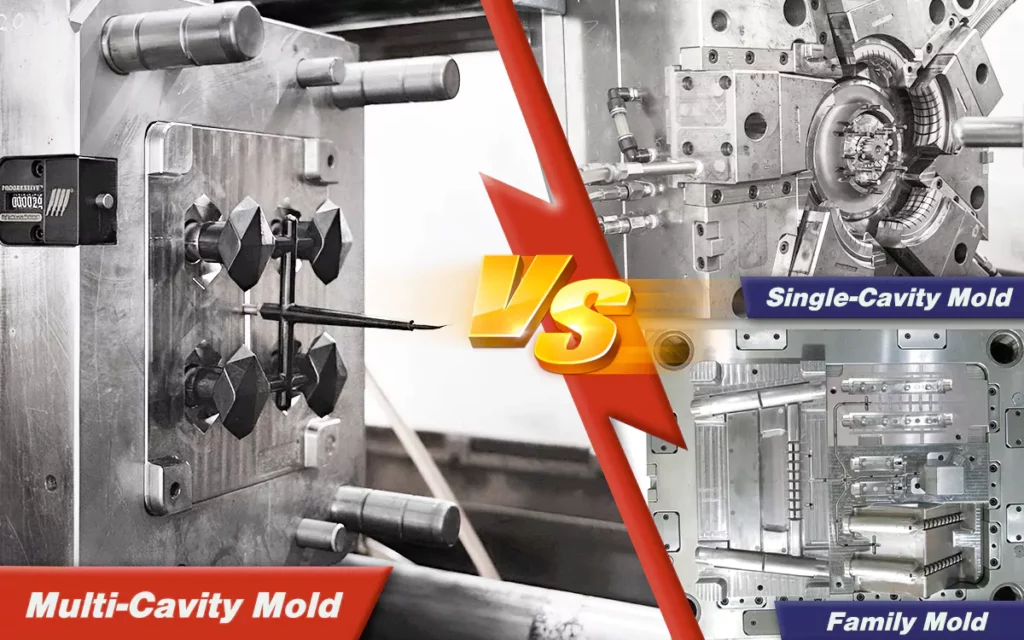

Single-Cavity Mold vs. Multi-Cavity Mold vs. Family Mold

Understanding the different types of molds used in moulage par injection is crucial to ensure you use the tools needed to produce a specific part. To help you understand that, here is a table to help you differentiate between single-cavity, multi-cavitéet moisissure familiale:

| Mold Type | Production Speed | Suitability | Use-Case |

| Multi-Cavity Mold | In one casting cycle, it can make several identical parts simultaneously. | Efficient for making a lot of things at once, cutting down on cycle time and cost per part. | Ideal for things that are in high demand and always meet the same standards. |

| Single-Cavity Mold | Each molding turn makes one part. | This mold fits parts that are complex and have low to medium production rates. | It offers more freedom in design and makes prototyping easy. |

| Family Molds | Family molds make it possible to make different parts with the same mold. | They are effective for small to medium-sized production runs with different parts. | They cost less to make tools and take up less room. |

Understanding The Differences of Each Mold Type:

When the primary determinants of production involve time and substantial demand, opting for a multiple-cavity mold frequently emerges as the preferred choice. This approach simplifies the rapid and simultaneous creation of numerous identical components, consequently resulting in elevated efficiency levels and diminished per-part expenditures.

However, the original cost of multi-impression molds is higher because they require more materials, labor, and energy. This makes them a better choice for manufacturers who need to make many products.

On the other hand, single-cavity molds are a good choice for smaller-scale productions where cost-effectiveness and shorter wait times are most important. These molds have a basic design and are easy to keep up with. However, because their cycle times are slower, they might not be the best choice for production de masse.

Family molds are useful for making prototypes and different product lines because they can make different parts simultaneously. However, the different shapes of the parts in a family mold can cause unbalanced filling et possible flaws in the cast. Careful consideration of this aspect is necessary during the design process.

Also, after casting, the different parts of a family mold must be separated by hand, which takes more work than single or multiple-cavity molds, where each part is made separately. As a result, family models may need more work after production, which could affect how well production works overall.

Ultimately, the choice between single-cavity, multi-cavity, and family molds depends on what needs to be made, how much needs to be made, how long it will take to get to market, and how much it will cost. When manufacturers know the pros and cons of each type of mold, they can make choices that align with their production goals et improve the molding process.

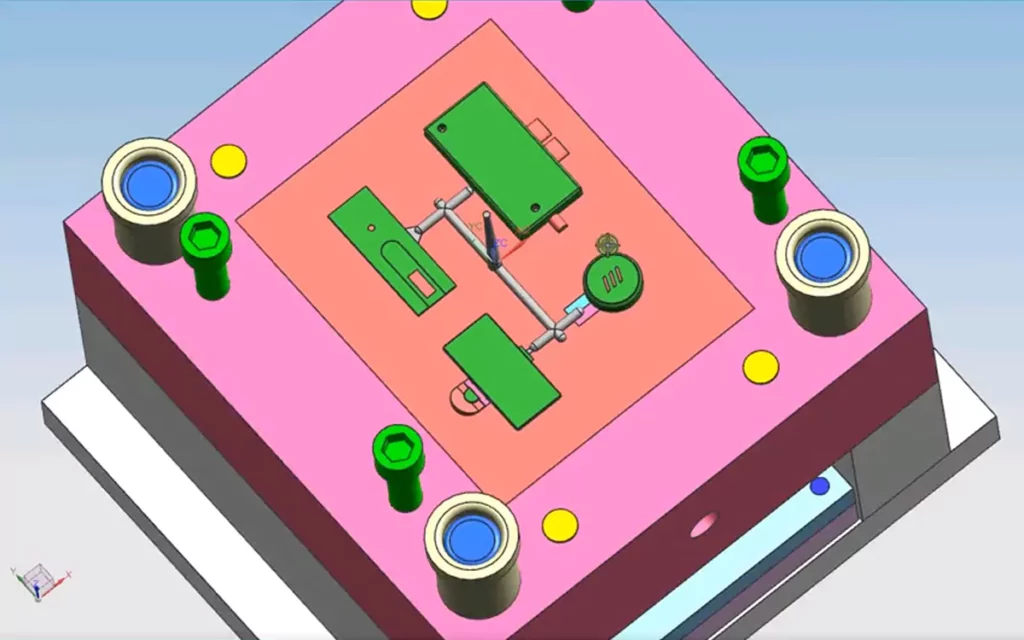

Tips to Improve Multi-Cavity Mold

Switching from a single-cavity mold to one that can make two, four, or eight parts at once seems like a simple way to boost production and cut costs per part. Nonetheless, the successful utilization of a multiple-cavity mold demands meticulous preparation and a keen focus on intricacies to guarantee its effective performance and the production of high-quality components. Let’s look at some essential ways to make multi-impression molds better.

Considerations for Gating:

- Proper gate design is vital for smooth plastic flow and even the filling of holes in molds with more than one cavity.

- Manufacturers frequently utilize tab gates, also known as edge gates, in multi-cavity molds due to their straightforward positioning and ability to handle flow stress effectively.

- Pin-style and hot-tip gates, often used in single-cavity molds, may not be suitable for multi-cavity injection molds because they are more complicated and could cause uneven flow.

Gate Placement Optimization:

- When transitioning to molds with multiple cavities, adjusting the gate’s original placement might be necessary to accommodate alterations in the part orientations.

- Working with application engineers early can help determine the best way to place gates on multi-cavity injection molds.

Optimizing the Design:

- For parts to work well in multi-cavity molds, they may need to be changed or tweaked from how they work in single-cavity molds.

- Adjust the multiple-cavity mold gate, use side-actions, add pickouts, or choose caoutchouc silicone liquide (LSR) to improve the design of a multi-cavity injection mold.

- Materials that flow well, like LSR, work well in molds with multiple holes. This makes family molds easier to use.

Side Actions and Pickouts:

- Side actions can be helpful for molds with only one cavity, but they can be hard to control when there is more than one cavity because of how the material flows.

- Pour production en grande quantité, inserts ou pickets that must be added by hand can be time-consuming and inefficient, so they must be carefully thought out or designed differently.

Additional Considerations:

- Follow general rules for injection molding, like angles de dépouille, wall width, material choiceet finition de la surface.

- Before investing in multi-cavity casting, prototyping parts with a single-cavity mold can help confirm designs, improve quality, and find cost-effective solutions.

Advantages of a Gradual Change:

- Use single-cavity molds to try different versions of pièces moulées before going on to multi-cavity molds to find the best design.

- Gradually switching to molds with more than one cavity helps speed development, get products to market faster, and lower potential problems.

By considering these tips and working with experienced application engineers, you can improve the designs of their multi-cavity injection molds. This will help make molding more efficient and make high-quality parts for less money.

Understanding Your Market and Product Demand Before Choosing a Mold Type

It’s always smart to know your market and have a clear idea of how much demand there is for your product. This way, you can create and make your product to save money. When it comes to injection molding, this is especially true.

Since making a mold takes a long time and costs a lot of money, product teams must research and choose the mold that fits the product and market demand the best.

But if you ever feel stuck, our expert designers and manufacturers can assist you at Prototool.