の世界に初めて足を踏み入れるのであれば 射出成形 製造業界で「スプルー・ブッシング」という言葉を聞くと、混乱するかもしれない。簡単に言えば、次のような部品である。 射出成形機 生産において重要な役割を果たしている。

しかし、スプルー・ブッシングがどのように機能するのか、スプルー・ブッシングを使用しながら最高の生産利益を確保するために考慮すべきことは他にもあります。これらの詳細について興味がありますか?それでは、スプルーブッシングのすべてを学びましょう。

スプルー・ブッシングとは?

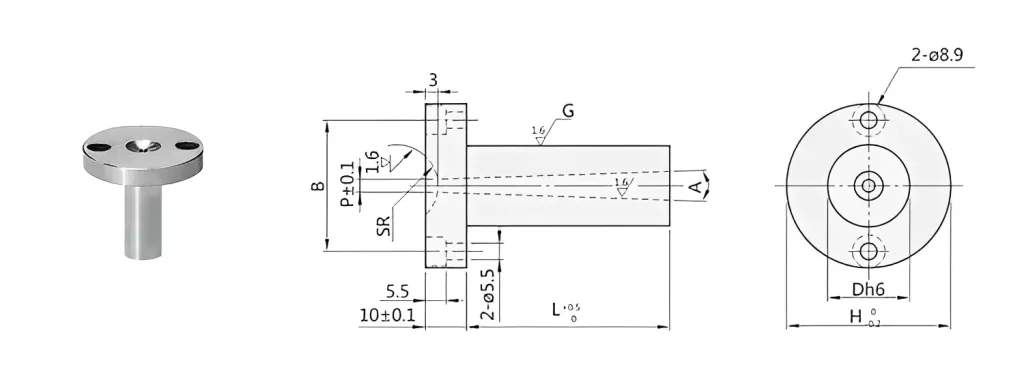

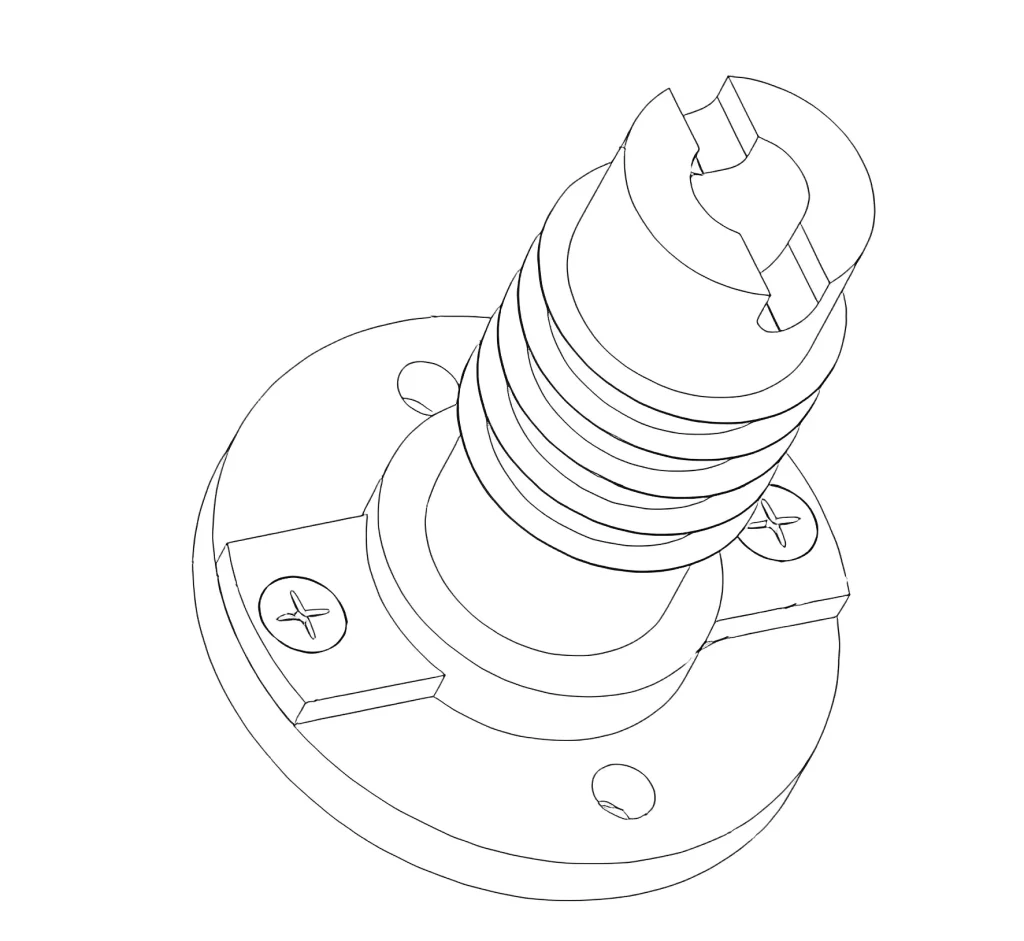

スプルーブッシュはスプルー内部の部品です。硬化鋼で作られており、押出ノズルを受け入れるのに役立ちます。スプルーブッシュは、溶融プラスチックがそれぞれの金型キャビティに移送されるために必要な開口部を提供します。これらの部品はスプルーの剛性を高め、冷却時間の短縮に貢献します。スプルーは、ピッカーやその他の産業用ロボットが成形品を取り出す際に拾い上げるため、頑丈でなければなりません。

スプルーブッシュは、ボルトに似た形と大きさをしている。スプルーブッシュはスプルーの取り付けを補助するものであるため、射出圧力が高いときにスプルーが分離しないように、2本のボルトで固定します。スプルーブッシュは、熱間加工で作られます。 スチール SKD61 また、耐熱性、耐摩耗性にも優れている。

スプルー・ブッシュは多くの場合、硬化鋼または銅ベースの合金で作られています。状況によっては、耐摩耗性や耐食性、熱伝導率を高めるために、超硬合金でライニングされることもあります。超硬ライニングされたスプルー・ブッシュは、研磨性樹脂を使用する場合に非常に役立ちます。

スプルーブッシュの主な役割は、射出成形の過程でプラスチック材料が漏れるのを防ぐことです。そのためには、スプルーブッシュをフィードスロートに合わせて適切なサイズにする必要があります。金型スプルーの球面半径(SR)は、射出ノズルの球面半径より1~2ミリ大きくなければなりません。

こちらもお読みください: 射出成形でよくある問題、ショートショットの特定と修正

どのように機能するのか?

射出成形の工程が始まると、使用されるプラスチック材料がスプルーブッシュに送り込まれる。そこから、金型内のさまざまな場所に溶融プラスチックを運ぶ流路であるランナーを通って移動する。溶けたプラスチックが流路の端に達すると、金型は完成する。ランナーは最終的にゲートにつながる。ゲートとは、プラスチック材料を最終製品が作られる金型キャビティに導く小さな開口部である。その ゲート はランナーシステムの末端に位置する。

スプルブッシュは、金型のキャビティが効果的かつ均一に充填されるようにするために不可欠です。溶融プラスチックの流量と圧力を管理し、適切な圧力を維持することでエアポケットや部分的な充填などの問題を防ぎます。さらに、スプルーブッシュは、理想的な加工条件を維持するための温度制御など、他の特性を備えた製品も開発される可能性があります。

型開きの工程では、スプルーとランナーシステム、スプルーブッシュは通常、最終製品から分離され、型開きの前に取り外されます。これは、プラスチック材料が冷えて金型内で固まった後に行われます。このため、製品を原形のまま金型から取り出すことができる。

結論から言うと、スプルブッシュは射出成形で使われる部品で、液状プラスチックが金型キャビティに入るための導管として機能します。この部品はスプルーブッシュとも呼ばれます。射出成形プロセスの重要な一部であり、金型に材料が適切に充填されていることを保証するのに役立ちます。

スプルーブッシングの種類:

射出成形で使用されるスプルブッシュには、2つの一般的なタイプがあります。これらのタイプは、次のとおりです:

● コールド・スプルー・ブッシング

A コールドスプルーブッシング は加熱されず、二次加工で取り除かなければならないスプルーができる。このブッシュタイプは金型に挿入され、成形機のノズルと金型室の間に溝を形成するのに役立ちます。球形の半径とO型の穴の開口部は、コールドスプルーブッシュの最も重要な2つのノズル寸法です。

● ホット・スプルー・ブッシング

コールド・スプルー・ブッシングと同様に、ホット・スプルー・ブッシングも金型内に配置されます。しかし、これらのスプルーブッシュは、金型チャンバーと金型ノズルの間に高温の経路を提供します。さらに、スプルーブッシュ内にある発熱体が、溶融した樹脂やプラスチックがスプルーブッシュを通過する際、高温に保つのを助けます。

設計と運営:

スプルーブッシュの球面半径は通常0.50″または0.75″で、ノズル半径ではなく表面が平らなフラットタイプブッシュもあります。バイヤーはまた、以下を含む他のいくつかの寸法を指定する必要があります:

● シャンクの長さ:

スプルーブッシングヘッドの下側からブッシングの端までのシャンクの長さを測り始めます。全長の測定と同様、この寸法にはノズルは含まれません。

● チップホールドの直径:

ノズルシート上の入口孔の直径は、「O」径としても知られるチップホールド径によって表される。この測定値は、「ゲート径」または「メルトパッセージ径」とも呼ばれることがあります。どのような名称であれ、この測定値は、事実上、ノズル先端と材料がスプルーブッシングに入るところをつなぐホールドです。

● 全長:

スプルー・ブッシングの全長を測定する場合は、ノズルの測定部分を除いて、始点から終点までの長さを測定してください。

こちらもお読みください: 射出成形におけるスプルーの設計と位置の重要性

スプルーブッシングによくある問題:

スプルーブッシュの何が問題で、どのような問題が起こりうるかを知ることは、これらの部品の機能を理解する上で極めて重要な要素である。

生産工程における2つの重要な目標である加工上の問題を回避し、サイクルタイムを改善するためには、生産現場でスプルー・ブッシングの問題を特定し、解決する方法を知ることが不可欠です。このため、スプルーブッシングの問題を検出し、解決する方法を知ることが重要です。

表面仕上げの問題:

スプルー・ブッシングを検査する際には、錆、傷、孔食、その他の機械痕に注意してください。スプルーブッシュの内径にこのような凹凸がある場合、スプルーがブッシングの中で詰まっている可能性があります。腐食性物質や研磨性物質による孔食が原因である可能性もありますが、このような状況のほとんどは、人為的なミスや機械の不適切なメンテナンスによって引き起こされるものです。

ブッシュの中に詰まったスプルーを取り除こうとすると、内部に傷がつき、エッジにロールが発生する。

真鍮の棒を使ってスプルをノズルシート側から押し出す従来の方法では、その位置で棒を操作するのが難しいため、問題が生じる可能性がある。

この場合、プロパンかMAPガス・トーチで真鍮ネジを熱し、それを金型のパーティング・ラインからスプルーに入れることで問題を解決できる。これで望ましい結果が得られるはずだ。

適切な温度まで冷やせば、真鍮製のペンチでスプルをこじ開けることができる。スプルーはかなり高価なので、ネジ、ドライバー、各種プライヤー、ゲートカッターなど、硬化鋼でできた器具の使用は避けることをお勧めする。

縮小する課題

成型されたスプルーは、わずかに収縮させることによって、ブッシングのテーパー・ロックの一部を減らす必要がある。スプルーがどのような材料で製造され、どの程度しっかりと詰め込まれているかは、スプルーの収縮具合に直接影響します。

浅い成形材料を使用しない場合 縮み そのため、適切な収縮量を達成することは、 問題になりません。フィラーを密に含んだ非晶質材料と液晶ポリマー(LCP)は、このカテゴリーに入る2種類の材料です。

一方、収縮が問題になるのは、成形によってスプルーに材料が詰め込まれすぎて、適切な収縮ができなくなった場合である。ゲートが凍結した後、充填圧力がかなりの時間残っている場合、これは頻繁に発生するものである。

さらに、スプルー回収を急いでいる間にスプルーオリフィスがまだ液体である場合、または着色剤を組み込むために高い背圧が使用される場合、スプルーはオーバーパックになる可能性があります。これに対して、スプルーが回収されている場合は、スプルーがオーバーパックになる可能性があります。

徐々に収縮する可能性のあるもう一つの状況は、サイクル期間がかなり早いにもかかわらず、金型のブッシュが十分に冷却されない場合である。

ノズルシートの問題

各工程の開始時には、スプルーブッシングノズルの目視検査が不可欠である。この検査では、作業者は、エッジの圧延、欠け、亀裂、バリ、へこみ、プラスチック、残留物の蓄積など、故障の可能性が高い兆候を探す必要があります。

各製造工程の後、品質保証のためにノズルシートも検査する必要がある。そうすれば、金型がまだ使えるうちに部品を修理しなければならないかどうかを判断しやすくなる。

ノズルシートの修理について、最も頻繁に利用される方法は、リフェイスツールと超硬カッターの2つである。超硬カッターを初めて使用する前に、刃先の半径を確認する必要がある。

カッターは常に適切な公差で作られているわけではありませんが、スプルーブッシングのノズルシート半径の寸法が正確であることを確認することは、問題を回避するために不可欠です。スプルーブッシングの座面を加工する場合、ロータリー放電加工機を使用すると、溶融プラスチックの流出やキャリッジのブローバックのリスクを低減できます。

スティップル仕上げを採用するのも、将来的なダメージを素早く発見し、補修するための良い方法だ。

結論

スプルーブッシュは、射出ホースから金型キャビティへの溶融材料の流れを円滑にすることで、製造に欠かせないものです。スプルーブッシュは、大きな機械の一部品に過ぎませんが、注意深い監視と適切な整備が必要です。

したがって、製造工程を成功させるためには、その適切な性能に寄与する数多くの部品や側面を十分に認識することが極めて重要である。

について、さらに質問がある。 スプルーブッシュ?私たちの専門家にお気軽にお尋ねください。 プロトツール・ドットコム.