試作品の表面処理における粉体塗装と塗装の比較

プロトタイプにおける粉体塗装と塗装の主な違い(塗装方法、費用対効果など)をご覧ください。

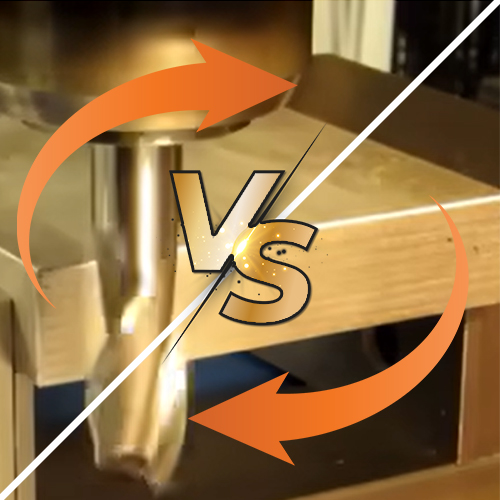

Correct Operation of Conventional Milling and Climb Milling

Explore conventional milling vs. climb milling. Find their applications and benefits. Rely on our CNC milling expertise for optimal results.

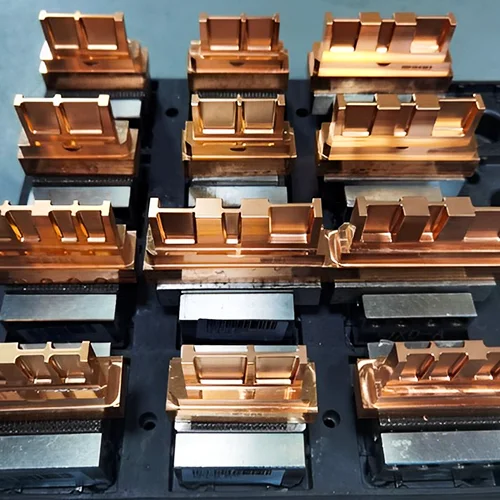

Comparing Electrode Machining Process on Different Materials: How It Works?

Electrode machining is among the newer metal processing techniques, compared to rotating cutters, shearing, and forging. This machining process passes rapidly pulsed high-voltage electrical discharges (sparks) across the gap between the electrode and the grounded workpiece. As a result, it helps remove the material from the workpiece by erosion. This way, even the most complex and intractable material can be cut and machined with very little bulk heating and virtually no application of macro forces, provided that the material is electrically conductive. This results in very low distortion and no addition of meaningful residual stresses to the workpiece. But wait! Why should you opt for electrode machining for your production […]

CNC離型は手動離型より優れているのか?

CNC離型は、射出成形金型から部品を取り出すための自動化されたアプローチである。これにより、技術者は機械加工プロセスを効率的に行うことが容易になります。多くの技術者はCNC離型とその仕組みについて詳しく理解していませんが、理解不足は生産工程での問題につながる可能性があります。CNC加工のプロフェッショナルである私たちPrototoolは、脱型を詳しく理解するお手伝いをいたします。そこで、この脱型アプローチについてのすべてを学ぶために、このまま読み進めてください。医療業界におけるCNC加工の利点と応用 CNC脱型の簡単な概要:CNC脱型は、CNCアンモールドまたはCNCリリースとしても知られ、プロセス [...] です。

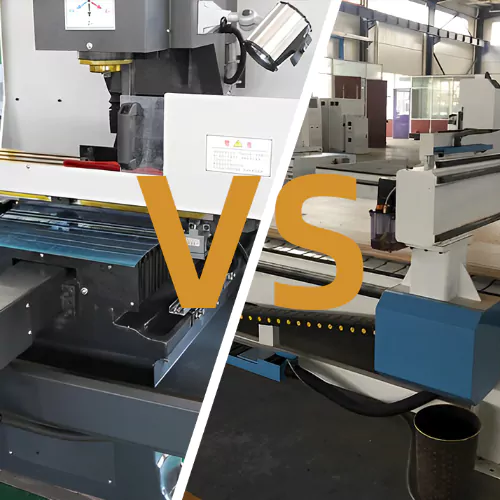

CNCレーザー切断機101:詳細な購入ガイド

レーザー切断に飛び込む最初の経験は、少し圧倒されたままに感じるかもしれません。どんな選択肢があるのか?どんな材料を使うべきか?このCNCレーザー切断機の設定をどの材料に使うべきか?この包括的なガイドでは、最高のCNCレーザー切断機を利用し、取得するための本質的な側面を掘り下げる。 それでは、この驚くべきツールに関する豊富な知識を得るために熟読を続けてください。レーザーカッターとは何ですか?レーザー切断は、主に熱処理手順です。このプロセスでは、集光されたレーザービームが材料を溶かします。同軸ガスジェットを使用して溶融材料を排出し、スリットを作成します。レーザービームまたは加工物 [...]...

CNC Mill vs. Router – Comparing Speed, Function, Accuracy, Cost, and More!

According to Fortune Business Insight, the global CNC machine market was estimated to be worth USD 83.99 billion. This market is further expected to grow to USD 140.78 billion by 2029. That said, CNC machines are common automated machines manufacturers use to process materials and create diverse products. But how do you know which CNC machine suits your product’s production demands? Specifically, common machines like CNC routers and CNC mills help make manufacturing tasks easier and more efficient. For choosing one of these machines, it’s important to understand their differences and cost estimates. In this guide, we will discuss a detailed comparison between CNC mill vs. router and how these […]

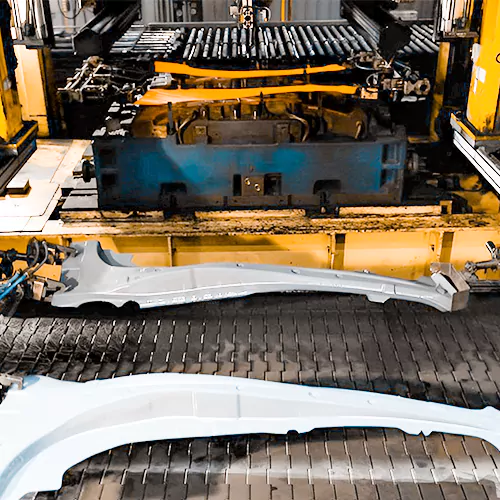

熱成形と射出成形 - どちらが優れているか?

あらゆる産業で使用されているプラスチックは、自動車のボディ部品から人体部品まで、さまざまな用途に適応性と強度を提供する。それぞれの用途には、仕様に沿った部品の成形が可能な独自の製造技術が必要です。熱成形と射出成形は、プラスチック部品を作るための最も一般的な製造方法の2つであり、用途に応じて明確な利点があります。予算と生産ニーズに合った製造工程をお探しなら、熱成形の違い、利点、工程、そして一般的な射出成形との違いを把握することが重要です。お客様のお役に立つために、この製造工程とどのような違いがあるのか、そのすべてをご紹介します。

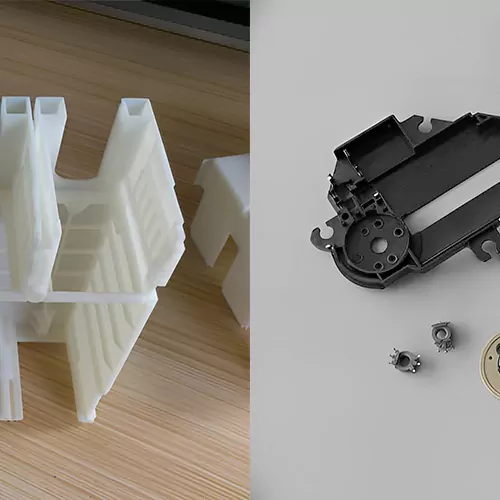

3Dプリンティングと射出成形、どちらが優れているか?

あなたのプロジェクトでは、すでに制作方法の候補を検討していることだろう。では、どの製造方法がベストなのでしょうか?3Dプリントと射出成形、そしてその理由は?この詳細なガイドでは、射出成形と3Dプリントの2つのプロセスを比較対照し、それぞれの長所と短所を明らかにすることで、プロジェクトに命を吹き込むための選択をお手伝いします。正しい製造の選択をする3Dプリントと射出成形は、どちらも優れた製造方法ですが、非常に異なるものであり、多様なプロジェクトを完成させるのに役立ちます。これは完全にあなたの要件に依存します。射出成形の方がより専門的であるように見えても、状況は変化しており、3D印刷は[...][...]になりつつある。

プラスチック製品の肉厚:最も推奨されるリファレンス

射出成形プラスチック製品の肉厚は、その品質に大きく影響します。肉厚が薄すぎると、強度と剛性の要求を満たし、大型で複雑な製品のキャビティに充填することが難しくなります。肉厚が厚すぎると、原材料を無駄にするだけでなく、プラスチック製品の内部にすぐに気泡が発生し、製品の外観に凹みなどの欠陥が生じます。同時に冷却時間も長くなる。その結果、経済的な観点から、プラスチック製品を薄くすることは非常に重要です。プラスチック射出成形用金型を製作する際には、プラスチック製品の厚みが成形工程の要求に合っているかどうかを検討する。もし

最高のデジタル製造企業の条件とは?

Today, we are in the midst of the fourth industrial revolution, which is being propelled by the overall digital manufacturing processes. Creators and consumers can use software to create digital twins of physical products, big and small. Augmented and virtual reality makes it possible to see and try these things. Cloud computing facilitates global electronic sourcing of the product’s components. Every component’s usage can be tracked and monitored along the supply chain. During this period, digital manufacturing companies mushroomed one by one. The fourth industrial revolution will likely be driven by the digitization of all stages of production. As opposed to earlier processes, which were spurred by new production techniques, […]