Spray coating encompasses spray painting, spray oiling, and spray zinc. In this context, spray painting and spray oiling are considered the same process and will be collectively referred to as spray painting. Powder coating, also known as plastic spraying, is a different process and will be referred to as powder coating in this article. Spray zinc, often used for large architectural steel structures or high-demand metal workpieces, will not be the focus of this discussion. Let’s talk about powder coating vs painting in prototype today.

Among all the surface treatment types mentioned, spray painting is arguably the simplest. It involves pouring paint into a specialized spray painting device and using a spray gun to coat the workpiece. The piece is then left to dry naturally or is dried using high heat. Thus, it’s a relatively straightforward physical process.

The equipment and techniques used in these processes vary, leading to differences in texture and cost.

Differences Between Spray Painting and Powder Coating

Let’s briefly outline their key differences:

Spray Painting vs. Powder Coating: Spray painting is a technique of dispersing liquid paint, commonly referred to as paint into fine dust particles which are blown on the surface of an object using compressed air. Powder coating, on the other hand uses compressed air to spray powder in a high-voltage electrostatic field. The powder particles are then drawn towards the surface of the object using an electric field.

The Correct Term for Powder Coating: Powder coating as a process is properly referred to as “electrostatic powder coating.” It’s not the sort of task that can be accomplished using just an ordinary spray paint gun. Equipment for powder coating comprises a powder supply barrel using compressed air, a High-voltage electrostatic generator and an electrostatic spray gun. Outdoor and indoor powders are the plastic powder used in this process. The main kind is Outdoor powder made of epoxy resin, which in terms of composition differs fundamentally from the paint.

Analysis of Characteristics For Comparing Powder Coating vs Painting

Powder Coating Process

1. No Solvents in Powder Coatings:

Powder coatings do not contain any solvents and are 100% solid. This aspect addresses pollution issues caused by solvents during manufacturing, transportation, storage, and application. It improves the working conditions for operators and benefits their health.

2. Simplified Coating Process:

The powder coating process involves just three steps: spraying the powder, curing, and cooling, allowing for a one-step film formation. This simplicity significantly streamlines the coating process, shortens the production cycle, and enables product output on the same day. In electrostatic powder coating, the integration of automatic coating machinery and a recycling system can lead to automated production, saving energy and resources and enhancing productivity.

3. High Utilization Rate of Powder Coatings:

Powder coatings can be directly applied to the surface of the object and cured by baking to form a coating. Unused powder can be collected and reused, with a utilization rate of over 95%.

4. Durable and High-Performance Powder Coatings:

Powder coatings can be made from resins that are insoluble at room temperature or high-molecular-weight resins that cannot be liquefied. This results in high-performance coatings with various functionalities. The absence of solvents in the preparation or film formation process prevents pinholes in the coating, making it denser.

5. One-Time Coating Possibility:

A single application of powder coating can achieve a film thickness of 50 to 300 μm without the dripping or sagging issues common with thick paint applications. It also avoids solvent pinholes and defects associated with thick film coatings, and offers high edge coverage. In contrast, paint typically requires multiple applications to achieve a similar thickness or quality.

6. Challenges in Color Changing:

Unlike paint, which can be mixed on-site, the color of powder coatings is predetermined at the factory. Changing the color requires altering the powder coating formula, making quick color changes challenging. Electrostatic spraying necessitates thorough cleaning of the spray gun, powder feeder, spray chamber, transport pipes, and recycling system during color changes, especially when switching between dark and light colors.

7. Difficulty in Achieving Thin Films:

Due to the principles of electrostatic spraying, the thickness of powder coatings is generally above 50 μm. Even with high-quality powder coatings and optimal conditions, achieving a film thickness below 40 μm is challenging.

8. Slightly Inferior Surface Smoothness:

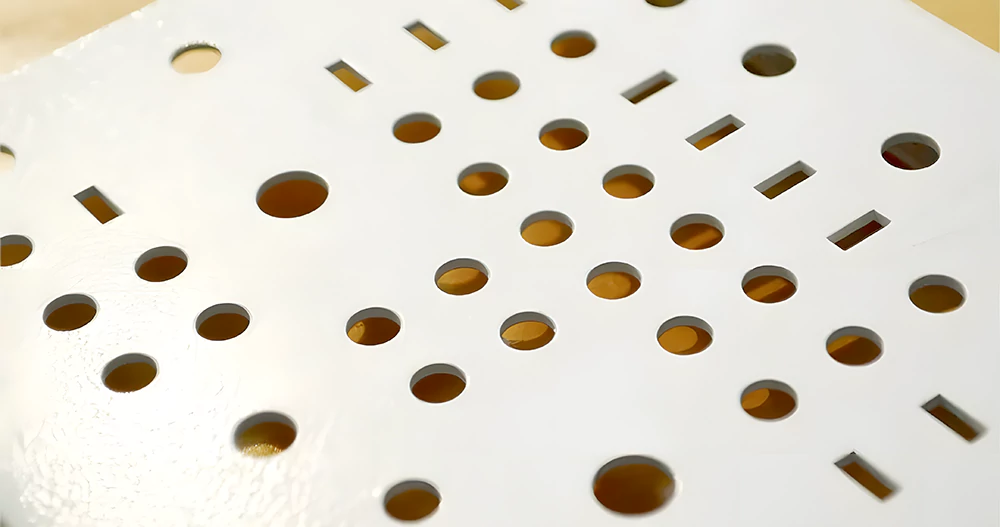

Powder coatings, which rely on heat-induced melting and leveling on the object, have a higher melting viscosity. This can result in a slightly orange-peel texture, making the coating less smooth than paint.

9. Certain Limitations:

The limitations of the powder coating process are mainly in three areas: First, since the curing temperature of powder coatings is generally above 160°C, this restricts their use on heat-sensitive products like plastics. Second, as most powder coating processes use electrostatic spraying, the object must be conductive. Non-metallic objects require conductive treatment and must withstand temperatures above 160°C.

Spray Painting Process

1. Wide Variety of Paints:

China categorizes paints into seventeen major types, with thousands of varieties available, and new types are continually emerging. Users can select the most suitable paint based on product performance, usage, and environmental factors to achieve optimal coating results.

2. Comprehensive Process Techniques:

Spray painting adapts well to various methods, including brush painting, dip coating, flow coating, roller coating, knife coating, air spray painting, high-pressure airless spray painting, electrophoretic painting, and electrostatic spray painting. Among these, brush painting, air spray painting, and electrophoretic painting are widely used.

3. Lower Initial Equipment Investment:

Spray painting equipment mainly includes spray guns, air compressors, oil-water separators, and necessary air hoses. Compared to the substantial investment required for powder coating equipment, spray painting involves less initial capital, lower production costs, and quicker capital recovery.

4. Simplified Pre-treatment Process:

In spray painting, thanks to the excellent rust-prevention properties of primers and their good adhesion to both substrates and topcoats, the corrosion resistance of the coating is significantly enhanced, ensuring the longevity of the coating. Only degreasing and derusting treatments are needed before applying the primer, thereby simplifying the pre-treatment process, saving production costs, and improving efficiency.

5. Longer Production Cycle and Higher Overall Cost:

Spray painting involves more steps than powder coating. During application, it requires the use of primers, putties, thinners, and topcoats, with drying time needed between each step. Some paints also require heat drying. Therefore, considering material consumption, energy use, and labor costs, the overall cost of spray painting is higher than powder coating, and the production cycle is longer.

6. Poor Environmental Performance:

Harmful to Operators’ Health: Paints contain organic solvents that can volatilize into the air during application and curing. Air spray painting produces a significant amount of overspray and paint mist, which is harmful to health, necessitating the use of protective masks by operators.

7. Higher Fire Hazard Compared to Powder Coating:

Spray painting poses a higher fire risk than powder coating for several reasons: First, the organic solvents in paint are highly volatile and can easily ignite or explode upon contact with open flames or sparks. Powder coatings do not contain organic solvents, thus presenting a lower risk. Second, the flash point, ignition point, and ignition energy of paint are lower than those of powder coatings, leading to faster combustion spread. Lastly, the ventilation equipment, working environment, and operational procedures in air spray painting are generally less advanced than in powder coating, increasing the risk of fire.

It’s important to note that while spray painting has a higher fire risk than powder coating, in the rare event of an explosion, the intensity and destructive power of a powder coating explosion can be much greater than that of liquid paints.

Powder Coating vs Painting Overall Comparison

Environmental Impact: Powder coating is often seen as being less detrimental to the environment than standard spray painting. It emits lesser amounts of volatile organic compounds (VOCs) that are harmful to human health and the environment.

Durability and Finish: Generally powder coating gives a thicker and more even finish than spray painting. It is more resistant to chipping, scratching and other wear and tear making it great for items requiring a hard finish.

Application Efficiency: Powder coating is more efficient in the application process. Extra powder can be salvaged and reused, thereby reducing wastage. However, spray painting tends to result in overspray and will require more accuracy for an even finish.

Curing Process: Powder coating curing process is faster compared to traditional spray painting. Heating allows for cure-coated items to be ready much faster.

コストを考慮する: Although this initial setup cost for powder coating can be more due to the equipment needed it will actually work out cheaper in ring term because of its efficency, life span and lower waste.