ダイカスト stands out as a prominent metal casting technique, characterized by the application of high pressure to molten metal within a 金型キャビティ, drawing parallels to the injection molding of plastics. This method is especially favored for producing a vast number of small to medium-sized castings, making it the most widely used among various casting processes. Compared to other casting techniques, die casting boasts a smoother surface finish and superior dimensional consistency. However, it’s crucial to note that improper operations and parameters can lead to a myriad of ダイカストの欠陥.

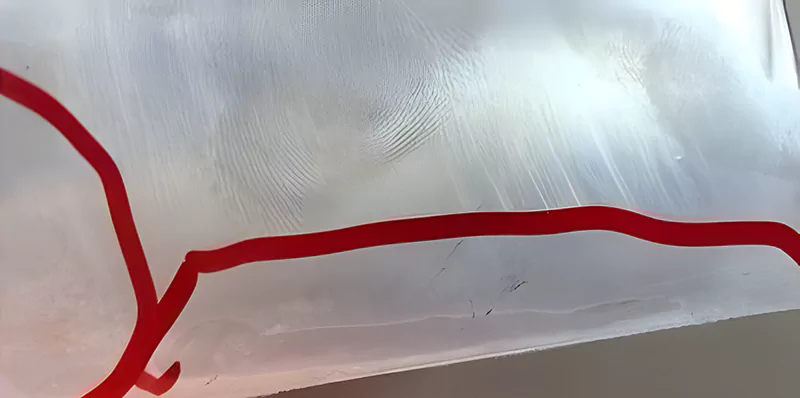

Flow Marks and Patterns in Die Casting

When examining the surface of die-cast parts, one might notice streaks that align with the direction of the molten metal flow. These streaks, distinct from the base metal color, exhibit non-directional patterns and do not show signs of progression.

Understanding the root causes of these flow marks is essential to mitigate such die-casting anomalies. Here are some primary reasons behind their formation:

Key Causes of Flow Marks

- Low 金型温度: An insufficiently heated mold can lead to premature solidification of the molten metal, resulting in these streaks.

- Poor Gating Design and Inadequate Sprue Positioning: The channels guiding the molten metal into the mold, if not designed optimally, can disrupt the flow, leading to these defects.

- Low Material Temperature: If the molten metal isn’t hot enough, it might not flow smoothly, causing irregularities on the surface.

- Slow Filling Speed and Short Filling Time: A slow or inconsistent pour can result in uneven cooling and solidification, leading to visible flow marks.

- Inefficient Pouring System: An improperly designed system can hinder the smooth flow of molten metal, causing these patterns.

- Inadequate Venting: Without proper venting, trapped air can disrupt the flow of the molten metal, leading to surface imperfections.

- Improper Spraying: Inconsistent or improper spraying can affect the temperature and flow of the molten metal, leading to these defects.

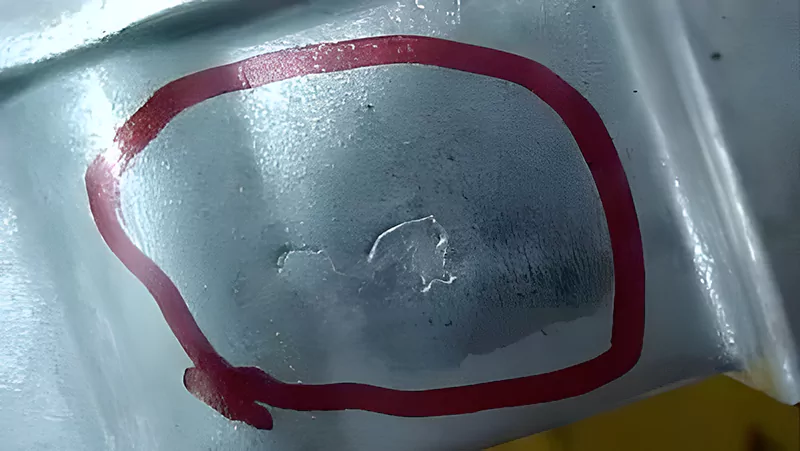

Dendritic Cracking in Die Casting

Upon inspecting die-cast parts, one might notice a network or tree-like pattern of cracks on the surface. These dendritic cracks can become more pronounced and widespread with an increasing number of casting cycles.

Understanding the root causes of dendritic cracking is essential for producing high-quality die-cast parts. Here are the primary reasons for the emergence of this defect:

Main Causes of Dendritic Cracking

- Cracks on the Die Casting Mold Surface: The presence of even minor cracks on the mold surface can lead to the formation of dendritic patterns on the cast part.

- Uneven Preheating of the Die Casting Mold: If a mold isn’t heated uniformly, it can cause the molten metal to solidify unevenly, leading to dendritic cracks. Ensuring consistent and proper preheating is crucial to prevent such defects in die-cast parts.

Cold Shuts in Die Casting

Cold shuts are one of the common imperfections in the die-casting process. When inspecting die-cast parts, you might notice distinct, irregular, and linear indentations on the surface. These indentations can either be penetrating or non-penetrating. They are typically narrow and elongated, and sometimes, their adjoining edges appear smooth. Under external forces, there’s a possibility that these areas might break or separate.

Understanding the root causes of cold shuts can help in mitigating this die casting anomaly. Here are the primary reasons for the emergence of this defect:

Main Causes of Cold Shuts

- Incomplete Metal Fusion: When two streams of molten metal meet but don’t fully merge, and there are no impurities between them, the resulting bond can be weak. This scenario often leads to the formation of cold shuts.

- Low Pouring or Mold Temperature: If the temperature of the molten metal or the die casting mold is too low, it can prevent the metal streams from merging properly, resulting in cold shuts.

- Improper Gate Location or Extended Flow Path: The position of the gate or an overly long flow path can hinder the smooth flow of molten metal, increasing the chances of cold shuts.

- Slow Filling Speed: A slow pouring speed can make the hot metal harden too soon and not completely fill the mold, which can result in cold gaps or defects. Ensuring an optimal filling speed is crucial to prevent such casting imperfections.

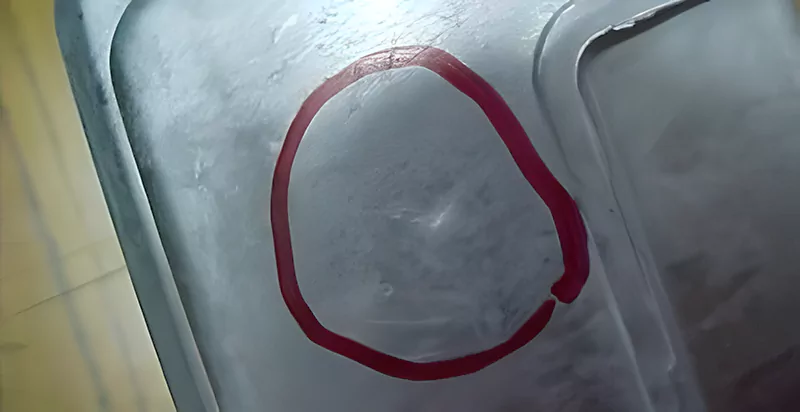

Shrinkage Defects (Sink Marks)

Visual Inspection:

Upon examining the surface of thicker sections of die-cast parts, one can observe smooth indentations that resemble the shape of a saucer.

Causes of Shrinkage Defects:

1. Contraction-Induced Issues:

- Improper design of the die-cast part leads to significant thickness variations.

- Incorrect positioning of the ゲートシステム.

- Insufficient pressure during the casting process and short holding time.

- Overheating in certain areas of the ダイカスト金型.

2. Inadequate Cooling System Design:

The design of the cooling system plays a pivotal role in the solidification of the molten metal. An inefficient design can lead to uneven cooling, which in turn can cause shrinkage defects.

3. Premature Mold Opening:

Opening the mold too early, before the metal has solidified completely, can lead to sink marks on the part’s surface.

4. Excessive Pouring Temperature:

Using a molten metal temperature that’s too high can exacerbate the shrinkage issue. It’s crucial to maintain an optimal temperature to ensure uniform solidification and minimize casting anomalies.

Recommendations for Avoiding Shrinkage Defects:

To mitigate the risk of shrinkage defects, it’s essential to focus on the design phase. Ensuring uniform wall thickness, optimizing the gating system, and maintaining the right casting parameters can go a long way in producing high-quality die-cast parts. Regularly monitoring and adjusting the process variables, coupled with routine mold maintenance, can further enhance the casting quality and reduce the occurrence of such flaws.

Die Marks

Visual Inspection:

On the surface of the castings, there are traces left from contact with the die casting mold cavity or step-like marks appearing on the surface of the castings.

Causes of Die Marks:

Ejection Component-Related Causes

- Wear on the end face of the ejector pin.

- Inconsistent adjustment lengths of ejector pins.

- Poor alignment between parts of the die-casting mold cavity.

Assembly or Moving Part-Related Causes

- Loosening of the inserted parts.

- Wear or loosening of moving parts.

- The side surface of the casting is formed by the interlocking inserts of the moving and fixed molds.

Soldering Marks in Die Casting

Visual Inspection:

Upon examination, one can observe small patches on the die-cast surface where the casting metal has unintentionally fused with the die. These patches, which can be either metallic or non-metallic, can peel off under external forces. Once they detach, the affected areas on the casting surface can appear either shiny or have a dark gray hue.

Causes of Soldering Marks:

- Presence of Residual Material: The die cavity surface may have remnants of metal or non-metallic substances.

- Impurities Introduced During Casting: During the casting process, impurities can be introduced and adhere to the die surface.

Lamination Defects

Visual or Destructive Inspection:

Upon inspection, certain areas of the die-cast part display evident metallic layers.

Causes of Lamination Defects:

- Insufficient Mold Rigidity: During the metal filling process, the mold may vibrate if it lacks the necessary rigidity.

- Plunger Movement Issues: Inconsistencies or crawling phenomena in the plunger’s movement during the shot phase can lead to these defects.

- Improper Gating System Design: The design of the gating system plays a crucial role in ensuring a defect-free casting. An improper design can lead to laminar defects.

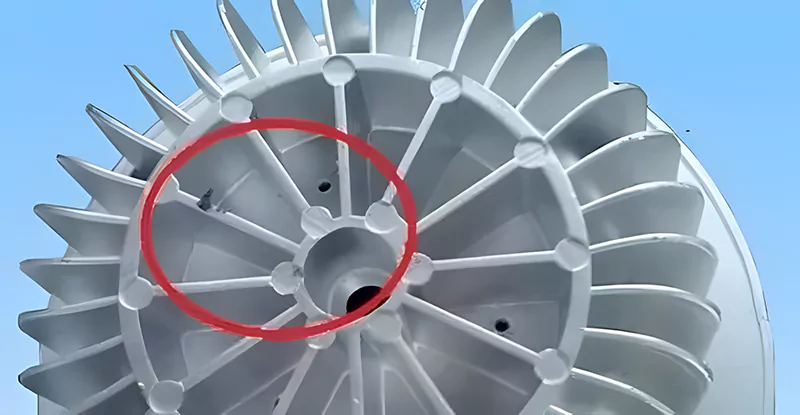

Metal Erosion in Die Casting

Visual Inspection:

Upon examination, certain areas of the die-cast part’s surface display a noticeable rough texture.

Causes of Metal Erosion:

- Gating System Issues: The improper positioning, direction, and shape of the internal gating system in the die-cast mold can lead to turbulent flow of the molten metal, increasing the risk of erosion.

- Inadequate Cooling: If the turbulent areas of the molten metal within the gating system are not cooled sufficiently due to casting conditions, it can exacerbate the erosion effect on the mold’s surface.

Cracking in Die-Cast Parts

Visual Inspection:

When the die-cast component is immersed in an alkaline solution, the areas with cracks appear in a dark gray hue. The damage to the metal matrix and the opening of the cracks can be linear or wavy in nature. These cracks are narrow and elongated, and they tend to propagate or grow when subjected to external forces.

Causes of Cracking:

- Alloy Composition Issues:

- Excessive iron content or insufficient silicon content in the alloy.

- Harmful impurities in the alloy at high levels can reduce the alloy’s ductility.

- Aluminum-silicon alloys or aluminum-silicon-copper alloys with high zinc or copper content.

- Aluminum-magnesium alloys with an overly high magnesium content.

- Casting Process Issues:

- Short mold retention time and brief pressure maintenance time.

- Parts of the casting with significant wall thickness variations.

- Force Imbalance:

- Excessive localized clamping force, leading to uneven forces during ejection.

Navigating the Complexities of Die Casting

There are many other types of die-casting defects, and we will have the opportunity to explain each of them carefully in the future. At Prototool, we pride ourselves on our expertise in die casting services. Our skilled team can fix various defects to ensure the end product is top-notch in quality and durability. We’re dedicated to being excellent and always getting better, making Prototool a dependable partner for your die-casting requirements. Trust us to navigate the complexities of this process and deliver exceptional results every time.