When it comes to producing plastic components for various uses, one of the most widespread methods is known as plastic injection molding. Manufacturers need a plastic injection mold designed according to the product that needs to be produced.

Now a typical question asked by those looking for a manufacturer is, “How much will the plastic injection mold cost?” It is also not unheard of for people to inquire about potential means through which the project’s overall cost can be decreased.

On the other hand, the solution is not always so cut and dry. This is because injection molds’ complexity, design, material choice, and sustainability concerns can vary greatly. The estimates provided for the various injection molding projects are different due to these various circumstances.

For a better sense of the investment that will be required and to prepare for methods to save expenses, it is crucial to understand the components that contribute to the costs connected with plastic injection mold. In this article, we will learn about all the effective ways that can help reduce mold costs.

8 Tips to Reduce Injection Mold Cost:

Start by Performing a Mold Flow Analysis:

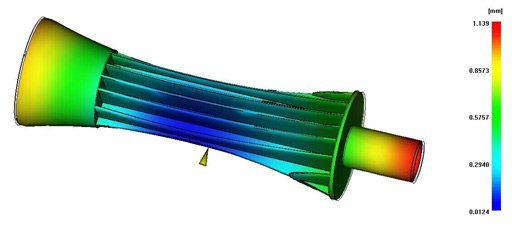

Few things can raise the cost of a plastic injection mold more than discovering flaws in the Formgestaltung after utilizing the Spritzgießmaschine. Professional software conducts a mold-flow study to simulate the molding process, incorporating mold design and the specific plastic formula.

Tips: know more about mold flow analysis

In the finished product, this digital prototype can illustrate essential product attributes. Potential air bubbles and shear stress are examples of these. Businesses can enhance their design before spending money on molds or goods since they have taken steps to identify potential flaws.

Plan the Mold Modifications:

Mold designers find it far easier to remove metal than it is to add it. As a result, a metal-safe design strategy relies on occasionally removing metal but never reinserting it. This is significant since injection molds frequently undergo multiple revisions before creating the right result.

Simplify or Remove Non-Essential Characteristics:

Molding in logos, textures, and other elements may help distinguish products and aid branding. In contrast, adding each extra touch to a mold will result in additional costs that raise the cost of injection molding.

Molding is sometimes required for compliance with legislation or other product requirements. Some prudent design methods might help keep excess costs to a minimum. Arial and Verdana are two mil-friendly fonts for numbers and letters, respectively. Also, keep the fonts at least 20 pt., and the cuts no deeper than.015-inch.

Opt for Designing Self-Mating Parts to Save Money on Injection Molds:

Sometimes the same piece can serve as both the front and back of a product. Consider the design of a container with a top and bottom snap together. Instead of creating two independent components, one portion that can link to the other from any direction might do the same.

Instead of making two separate molds, the top and bottom can be made from the same mold. Rather than sending half as many parts to the injection molding machine, it is more efficient and cost-effective to make twice as many.

Consider Overmolding to Reduce Manual Labor on Parts:

Simpler designs are less expensive than more sophisticated ones. Adding new features, on the other hand, may cost more but save money in the long term.

Consider the necessity of using gaskets to produce a seal. Businesses may pay more for injection molding if the Umspritzen that includes the gasket is included. At the same time, this feature may save you from overpaying for manpower to manually add the item afterward. In this scenario, paying a little bit extra for a more feature-rich plastic injection mold can deliver a more cost-effective choice for the complete manufacturing process.

Reduce or Eliminate Cosmetic Details:

Cosmetics, like non-essential features, can improve look and aid in branding. Each firm must assess if the potential benefits outweigh the additional costs.

Consider Multi-Cavity Molds as an Alternative to Manual Labor:

Separate components for various items may have traditionally been made individually and assembled afterward. It is sometimes more practical to construct any or all of these components as a single solid piece. They will not have to be screwed or glued together later. This technique can frequently result in a more durable finished product.

You can also opt for the option to mold two container components together and attach them using a molded hinge. This can reduce or eliminate the labor required to attach them afterward manually.

Hire Professional and Reasonable Plastic Injection Mold Manufacturers:

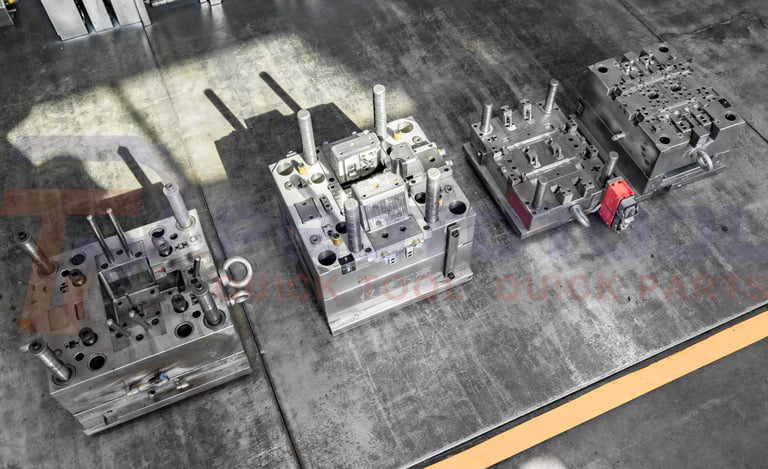

Choosing the best service choice can have a significant impact on both prices and production efficiency. For instance, a good prototyping service plan will cost less overall. Still, it may cost more for each part produced – even if you consider professional and reasonable manufacturing service providers like Prototool. Moreover, prototyping plans may charge for extras like inspection reports and impose other restrictions.

On the other hand, businesses should expect to pay more for production-ready injection molding but less per item produced. These plans should include reports, additional storage, and more flexible options.

Additional Mold Aspects to Consider:

● Wall Thickness & Coring

When you don’t have coring inside your part, you have an uneven Wandstärke and cooling, resulting in Einfallstellen within the park. Because you have more material, there’s a greater volume of material to cool, resulting in a longer Zykluszeit. The longer the cycle time, the higher the cost. You will also experience differential shrinkage because the part will shrink at a different pace in the thick parts, causing your part to go out of tolerance.

● Undercuts

Undercut characteristics make part ejection more difficult and, in some situations, impossible. Remove them if possible, although this may not be practicable if you want a side action, sliding shutdown, or pick out. Consider employing sliding shutoffs and pass-through cores or modifying the separating line and draft angles to make mold construction easier. These lower tooling costs because you avoid adding extra pieces to the injection mold, which raises manufacturing costs. In addition to the increased production costs associated with using hand-loaded inserts, the longer cycle times and manual mold operation may impact your piece part price.

● Annular Snapping

If you had an annular feature on the exterior of the tool in a cross-section, you would need some slide or lifter to get this geometry out of the way with this particular annular snap. There is a technique to get this out of the slide or out of the hollow of your core if you need it to. It is dependent on the material used. Since it will share this area, you can’t do it with glass field material or hard materials like polycarbonate.

Still, with something softer like nylon or even PBT polypropylene, high-density polyethylene, you can get this feature to snap out of the cavity record block. The 1:3 rule applies, stating that the feature should have three times the breadth compared to its height. There are also lead-in and lead-out radii, where sharp elements are fully distributed during expulsion or popping off.

● Drafting

The draft consists of angled wall pieces. The draft is required on injection molded parts because, without it, the object will not come out of the mold smoothly and will leave scrape marks. Also, if your section is textured or contains geometry, it will be ripped out if it is not sketched.

● Coring Using Pass-Through

Without pass-through coring, clips, snaps, and other similar features necessitate additional lifters or slides to remove the item from the mold. This raises the overall cost of injection mold design. Insert a cutout through the parallel feature for steel to shut off to employ pass-thru coring.

● Die-Lock

Run a draft analysis in the direction the part will come out of the mold to see if it is die-locked. Die-locked parts will require some action to remove the feature away at the mold opening. This will significantly reduce mold prices.

● Shrinkage

Almost every material shrinks and the rate at which this happens must be factored in. Plastics tend to shrink towards their centroid or center mass. Some plastics shrink linearly, so always read the specifications for your specific material. Try introducing a negative draft for better control for materials that shrink unusually.

Tips: know more about Schrumpfung.

Estimated Cost of Plastic Injection Mold Making:

The short answer is that a plastic injection mold can range anywhere from $100 for a 3D-printed low-volume injection mold to over $100,000 for a complex multi-cavity steel mold designed for high-volume production. This is typically the most significant fixed start-up cost associated with injection molding. In contrast, injection molding is the perfect method for mass-producing plastic parts at an affordable price because these expenditures are spread out over hundreds or thousands of individual pieces.

Schlussfolgerung:

It’s important to implement careful planning as you walk the tightrope between enhancing production and mold quality and cutting costs in your plastic injection mold. Making sure that the entire production process is not too heavy on your pocket is possible by cutting costs that won’t compromise the quality of the mold and final manufactured product.