Products made of plastic for industry and commerce are currently getting better and more varied. As a result, it is up to producers to raise the caliber of molds. It is due to the direct role that molds have in determining the quality of a product. Plastic injection mold polishing became necessary as a result of this.

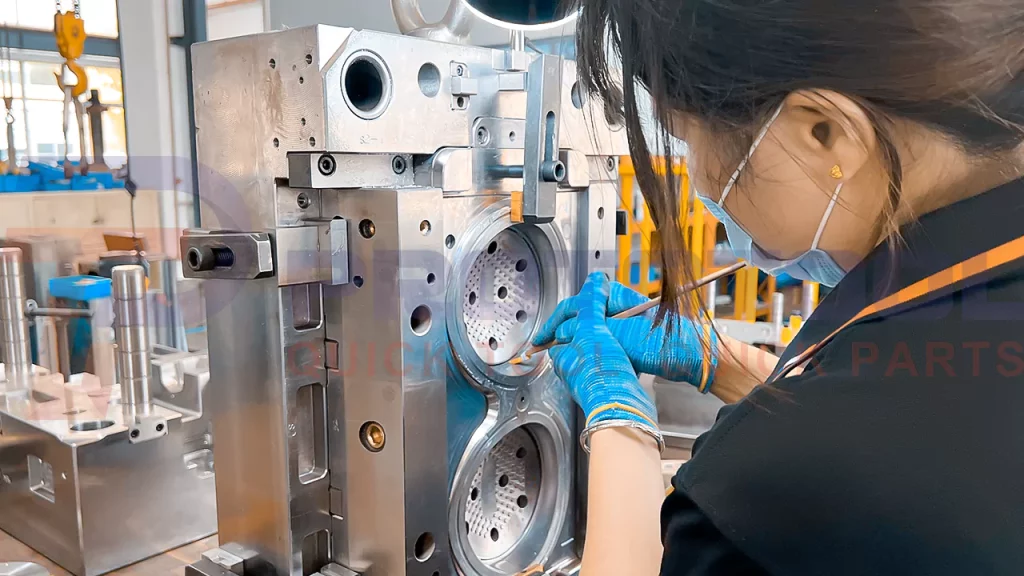

One of the last actions conducted by a mold maker is polishing the cavities and cores of a new mold tooling. People frequently forget to do this step. However, mold polishing is an essential operation to improve the quality of molds, so it’s important to comprehend the mold polishing procedure. These mold polishing processes will be explained in this article. Additionally, you will discover the best methods for maximizing the benefits of the mold polishing procedure.

Mold polishing: What is it?

An approach that aids in obtaining smooth mold surfaces is plastic injection mold polishing. This is accomplished by cutting and deforming plastic to remove the convex portions of the mold. In most cases, manual polishing methods for molds employ sandpaper, wool wheelsund whetstone strips.

Additionally, manufacturers will employ super-precision polishing techniques when the material needs a high-quality Oberflächengüte. It is accomplished by applying solutions with abrasives firmly and quickly to the workpiece surface using specialized mold polishing equipment. As a result, this approach makes it possible to achieve a surface roughness of Ra 0.008 micrometers.

Surface finishing for polishing purposes is very different from surface finishing for other sectors. Mirror processing is a common name for this kind of polishing. It adheres to strict requirements for geometric precision, smoothness, and polishing.

Plastic Injection’s Value Polishing mold

Techniques for polishing molds are crucial for making plastic molding tools. It greatly impacts the quality of the mold and the plastic component in addition to the mold itself.

Two main goals are typically the focus of mold polishing. The Kunststoffmaterial is firstly ejected quickly and smoothly. Molders can quickly and simply remove and demould plastic components because of the smooth surface finish of the mold. Consequently, you can be confident that the plastic will not adhere to the mold. You can stop injection molding problems from happening with this method.

Additionally, the aesthetics of the finished product are enhanced by a smooth mold surface. The wear and corrosion resistance of the plastic surface is simultaneously enhanced. Effective plastic mold polishing processes typically result in shorter injection cycle times.

Different Plastic Injection Mold Polishing Techniques

- Polishing a mold mechanically:

The primary method for polishing molds involves mechanically scraping away protruding (convex) elements from a workpiece’s surface to achieve a smooth one. Tools like oilstones, sandpaper, and wool wheels aid this laborious process.

In procedures with high surface requirements, ultra-precision polishing methods are used. Abrasives are forced into the workpiece surface for high-speed rotation in this situation, together with special injection mold polishing tools. Ra 0.008 micrometer, the greatest value for polishing molds, is this technology’s surface roughness.

- Polishing of ultrasonic molds:

The polishing of hard, fragile materials is accomplished using this method for plastic injection mold polishing. In this instance, the material is pretreated with the abrasive suspension before being exposed to an ultrasonic field. Ultrasonic waves are used by the suspension to hone and polish the workpiece’s surface. No workpiece deformation is a result of ultrasonic polishing because of its tiny macroscopic force.

- Polishing fluid for mold:

This method employs a flowing fluid containing abrasive particles to erode the workpiece surface. The hydrodynamic grinding process is assisted by hydraulics. Low pressure allows the polymeric component in the medium to flow. Frequently, silicon carbide powder makes up the abrasive particles.

- Polishing magnetic mold:

In order to form a brush under the influence of the magnetic field, magnetic abrasive is used in magnetic polishing. With better processing efficiency, this technique grinds the workpiece. It is a straightforward procedure that produces high-caliber results. Surface roughness of roughly Ra 0.1 micrometer is achieved using the right abrasives.

- Polishing of electrolytic molds:

The same principles that underlie chemical polishing also apply to electropolishing. To put it another way, it specifically dissolves the workpiece’s surface to provide a smooth finish. For even more notable effects, it does away with the cathode response influence.

Tips for Polishing Plastic Injection Molds

The polishing of molds is an essential step in the production of plastics. Thus, accuracy is crucial. You can maximize the effectiveness of your plastic injection mold polishing procedures by using the following advice:

- It would be best if you carefully check the workpiece’s surface for any dirt before machining a new cavity. Kerosene or other suitable solvents should be used to clean to make sure the oilstone cutting feature works as intended.

- Beginning with the most difficult areas and working your way down, polish a mold surface. Polishing certain dead corners could be challenging. Hence, before grinding the sides and flat surfaces, start with the deep bottom portions.

- Before smoothing the assembled workpiece, it is advisable to polish each component of a multi-component workpiece separately.

- On workpieces with wide sides or flat surfaces, use an oilstone to smooth out rough lines. Straight steel sheets can be used to inspect for undercuts and unevenness. As a result, you can guarantee the parts’ simple release and avoid any harm to them.

- The best protective effects can be attained by affixing sandpaper or a saw blade to the edge of interacting surfaces.

- For the finest results, polish the mold with an oilstone handle held horizontally. A workpiece will develop rough lines if there are too many steep slopes pressing down on it.

- Particularly when polishing molds using sandpaper that has been bamboo- or copper-pressed, the tool area for the mold should be greater than the sandpaper.

- Mold polishing equipment should closely resemble the mold in terms of shape. By doing this, you can avoid deforming the object when polishing.

Polishing Plastic Injection Molds: Things to Think About

There are a few crucial elements you need to think about before you attempt mold polishing. You can choose the best mold polishing method using this information. Major factors to take into account are

Considering the molding process:

Material made of plastic contracts as it cools. The shrinkage draws those components out from the cavity to assist them in grabbing the core more firmly. In this situation, the plastic item needs to be ejected from the core using the highest demolding power. Ausstoßkräfte der Form und Zyklusdauer steigen erheblich, wenn die Innenflächen nicht glatt poliert sind. Spritzgießen Entformungsschrägen und Formenpolieren gehen häufig Hand in Hand.

Die Kraft, die erforderlich ist, um das Teil aus der Kavität zu ziehen und vom Kern abzustoßen, ist geringer, wenn die Seitenwände des Teils verformt sind. Es gibt jedoch Situationen, in denen die funktionalen Anforderungen an Kunststoffteile die Entformungsschrägen nicht berücksichtigen. Unter diesen Umständen wird das glatte Polieren von Kunststoffspritzgussformen immer wichtiger. Daher ist es wünschenswert, die Spezifikationen für das Polieren der Form festzulegen, insbesondere für Teile, die nur geringe oder gar keine Entformungsschrägen aufweisen.

Kostenfaktoren für das Polieren von Formen:

Das Polieren von Formen ist eine Methode, die mehrere Schritte umfasst, beginnend mit dem Grobpolieren bis hin zum immer feineren Polieren. Je höher die geforderte Oberflächengüte ist, desto mehr Poliervorgänge sind erforderlich. Daher ist jeder Schritt mit entsprechenden Kosten verbunden.

Bei transparenten Spritzgussartikeln muss sowohl die Kavität als auch der Kern hochglanzpoliert werden. Außerdem hat sich der Preis dadurch erhöht. Einigen Brancheninsidern zufolge entfallen etwa 5% der gesamten Werkzeugkosten auf das Polieren des Werkzeugs. Für verschiedene Spritzgießbetriebe kann dies unterschiedlich sein.

Die materiellen Faktoren

Glänzende Oberflächen werden in der Regel mit Kunststoffpolymeren hergestellt. Zum Beispiel, egal was die Oberfläche der Form, Polystyrolstücke glänzender als solche aus Polyethylen niedriger Dichte. Außerdem neigen einige thermoplastische Elastomere, weiche Polyvinylchloride, Polyethylene und Polyurethane dazu, an hochpolierten Oberflächen zu haften. Das Polieren der Form mit einem sanften Strahlen ist für diese Materialien geeignet.

Kunststoffe, die stark und flexibel sind, halten auch ungleichmäßig polierten Oberflächen stand. Diese Stoffe bestehen aus schlagzähem Styrol, Polypropylene, und ABS. Acrylfarbensind jedoch spröde und unflexibel und können keine harten Oberflächenbehandlungen vertragen. Für diese Art von Materialien ist das Ziehpolieren vorteilhafter. Bei der Auswahl des perfekten Kunststoffs müssen Sie darauf achten, dass Sie die geeignete Formendbearbeitung wählen.

Zusammengefasst:

Für die endgültige Qualität von Spritzgussartikeln ist die Qualität der Form entscheidend. Das Polieren von Kunststoff-Spritzgussformen ist eine gute Möglichkeit, das Aussehen der geformten Produkte zu verbessern und eine qualitativ hochwertige Herstellung zu gewährleisten. Um die Vorteile Ihres Spritzgusses zu maximieren, sollten Sie die oben genannten Ratschläge befolgen. Prototool hat es sich zur Aufgabe gemacht, Ihre milliardenschweren Konzepte schnell in marktfähige, ansprechende und für den Verbraucher wertvolle Lösungen zu verwandeln. Für alle Ihre Anforderungen können Sie die besten Lösungen finden. Prototool ergreift zusätzliche Maßnahmen, um zu gewährleisten, dass Ihre Interaktion mit ihren Dienstleistungen unkompliziert und zuverlässig ist.