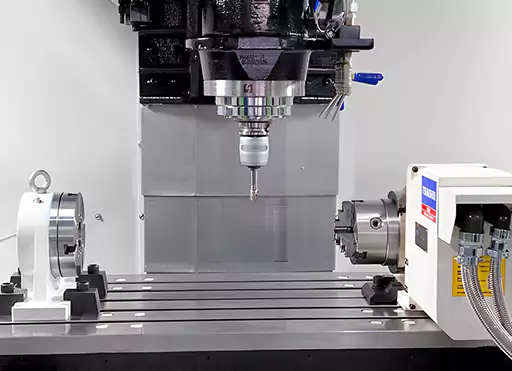

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining.

A 4-axis CNC-Maschine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities.

Without further delay, let’s dive into the details and uncover everything you need to know about these advanced machines.

What is a 4-Axis CNC Machine?

A computer numerically controlled (CNC) machine typically removes material from a workpiece to obtain the desired design, such as fräsen, Drehen, or routing center. Concurrently, a 4-axis CNC machine has four axes, three allowing for linear motion and one for rotation. A workpiece is shaped using a cutting tool mounted on a spindle that may be moved.

4-axis Replacements for entry-level CNC machines, CNC centers shine when working with massive quantities of material or sophisticated designs.

Working of 4-Axis CNC Machine:

To begin, basic CNC machines with three linear axes allow a spindle to be moved in three dimensions: X, Y, and Z. To put it another way, the cutting tool can move in different directions like back and forth, side to side, and up and down. An A-axis is found in a sophisticated CNC center.

Axis A is a rotating movement rather than a linear movement. It allows a workpiece to be rotated about the X-axis. As a result, the material can be removed from the front of a workpiece and any area of its surface and at any angle.

The fourth axis necessitates additional programming, complicating the preparatory stage. There aren’t many programming solutions designed to take a 2D or 3D model and turn it into a set of instructions for a CNC machine to follow, allowing for properly coordinated 4-axis operations. As a result, modern machines want a more professional approach, frequently assured by full-fledged CAM software that goes beyond main coding methods.

The A-axis is essential for most machining processes because it considerably improves a single machine unit’s variety of operations.

4-Axis CNC Machining Types:

Continuous Machining

Continuous mode CNC-Bearbeitung, instead of index 4-axis CNC machining, allows for removing material with a spindle even when a workpiece is being rotated about the fourth axis. Most of the time, it is used in lathes and turning centers, which are types of machines that produce symmetrical workpieces when viewed from the axial perspective.

Having pre-programming knowledge is preferable to operate such machines because it is more complex than index one machining. Primarily because the rotating and cutting operations, which are often carried out with various tools all at once, must be properly synchronized.

Index Machining

Index mode, also referred to as access mode or continuous mode, is a feature found on all 4-axis machines. When in indexing mode, the cutting tool remains inactive until the 4th axis has returned to its starting position. Various brakes, also called “indexers,” are utilized to ensure that the axis remains in a specific position before advancing to the next stage of the workpiece shaping process.

Die Vorteile:

Purchasing a 4-axis CNC machine is a wise investment for companies that aim to enhance their production procedure. The ability of a 4-axis machine to handle more complicated forms and designs can help the production process move forward more quickly. Some advantages of a 4-axis CNC machine include the following:

Better Accuracy and Precision

Because it can move in all four directions, a CNC 4-axis machine can generate more exact and precise outputs than those produced by a 3-axis machine (A, B, C, and D). Because of this, you can control the cutting process more precisely and complex machine shapes with greater freedom.

Less Human Error Issues

Since one computer controls each axis in such machines, operators can make adjustments quickly and precisely without interfering with the work of their colleagues.

Tragbarkeit

A 4-axis machine can operate in more than one area simultaneously. You are free to take it anywhere you see fit. The capacity of a 3-axis machine could be constrained by the dimensions of the shop in which it is housed.

Novel Design Principles

A 3-axis machine will never be able to manufacture the same designs that a 4-axis machine can create. You can create computer-generated models of real-world items or structures with the help of this program. Additionally, you may use it to develop intricate shapes and then bring those designs to life as tangible models.

Projects You Can Manage Using 4-Axis CNC Machining

You can accomplish many applications most effectively with 4-axis CNC machining. One of the cooperative projects involves the fabrication of individualized machine parts and components. Among these options is the production of replacement parts to enhance functionality or productivity. Creating the necessary components for manufacturing a finished product, such as an appliance, may also fall under this category. Other popular projects include:

- 3D modeling and printing.

- The creation of prototype or concept models.

- The manufacture of custom carvings such as hobby signage.

- Other typical projects include modeling in 3D and printing it.

The production of one-of-a-kind tools or dies is another use for 4-axis CNC machining. For a particular manufacturing method or application, this may necessitate the creation of a one-of-a-kind tool or die. For instance, in order to accurately complete the finishing of a surface, such as the bottom of a gear, it may be necessary to construct an eccentric tool or die.

In the above scenario, a four-axis CNC machining center could be instructed to mill one side of the component. The component could be rotated through ninety degrees, and the other side could be machined utilizing the same configuration.

Die aerospace industry is another one that makes use of 4-axis machining. Machining for the aerospace industry often includes turning, milling, and drilling, amongst other techniques. Because of its great precision, this machining is particularly useful for fabricating the numerous minute gears utilized in aerospace vehicles like aircraft and spacecraft.

3-Axis and 4-Axis CNC Machine: Which Should You Choose?

Considering your project and production demands, it is easier to pick the right CNC machine. However, if you’re unsure which machine is preferable for investment when you’re planning to offer CNC manufacturing services, you can consider the following:

- Precision and Accuracy Demands of the Parts: You can meet such part demands using 4-axis machines rather than 3-axis machines. This is because it is much simpler to stabilize all three axes on a machine with four axes.

- Teil Größe: Larger Parts are preferred for machining on 4-axis machining because they can accommodate the size of the part and give a more precise output. This is because 4-axis machines can handle the size of the item.

- The Level of Complexity of the Part: Machining on four axes is preferable for things with a high level of complexity since it enables more movement and produces more intricate shapes.

- Dauerhaftigkeit: 3-axis machines are better suited for operations requiring lighter duty and higher milling speeds. This is because it enables the use of a more compact cutter head and reduces the amount of vibration that can occur during the cutting process.

- Tooling: Sanding belts, spindles, and drill jigs are the types of softer tooling most suited for 3-axis machines. This is because these toolings have a greater degree of flex, making the tooling more prone to fractures and bending.

Schlussfolgerung:

4-axis CNC machines are more sophisticated iterations of the standard 3-axis machines. Adding an axis, the A-axis, gives modified centers the ability to rotate a workpiece along an axis other than the X-axis. A technique such as this broadens the scope of possibilities that can be provided by CNC machines, making it possible for these machines to make complicated patterns at lower prices and higher rates of production.

Complex four-axis machining intends to block the additional axis before cutting, while the continuous axis enables the machine to carry out turning operations. On the other hand, more sophisticated centers require more capable software to get a CNC equipment unit ready for material shaping. The use of 4-axis CBC centers has the potential to replace their 3-axis counterparts completely and is becoming increasingly common in all areas of industry.