Machines used for plastic molding for plastic pallets have made their place in a revolutionary shift in the industrial landscape, replacing conventional wooden pallets with innovative plastic alternatives. But is it really helpful? Honestly, the emergence of advanced plastic pallet machines not only enhances production efficiency but also optimizes space utilization and promotes environmental friendliness.

Not sure how? Then you’re at the right place. In this article, we’ll explore that and more in detail. So, keep reading to learn all about the benefits and usage of plastic molding for plastic pallets.

When Plastic Pallets Are Used?

Plastic pallets find extensive application across various industries, especially in supply chain logistics, due to their durability, versatility, and hygienic design. As the demand for injection-molded plastic pallets continues to rise, manufacturers are exploring efficient production methods, with plastic molding standing out as a key technology.

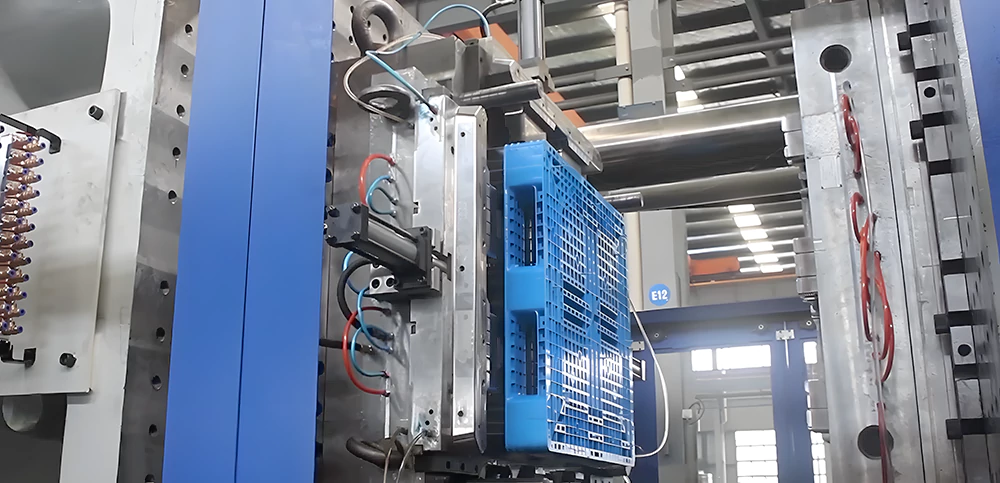

High Rigidity and Stable Clamping System

Plastic pallet injection molding stands out for its capability to achieve high rigidity. This is meticulously ensured through stress analysis, coupled with a stable clamping system employing four hydraulics.

This results in minimal mold deformation, precise accuracy, and sustained parallelism, effectively preventing any undesirable mold tilting. This not only guarantees the structural integrity of the plastic pallets but also contributes to their long-lasting durability.

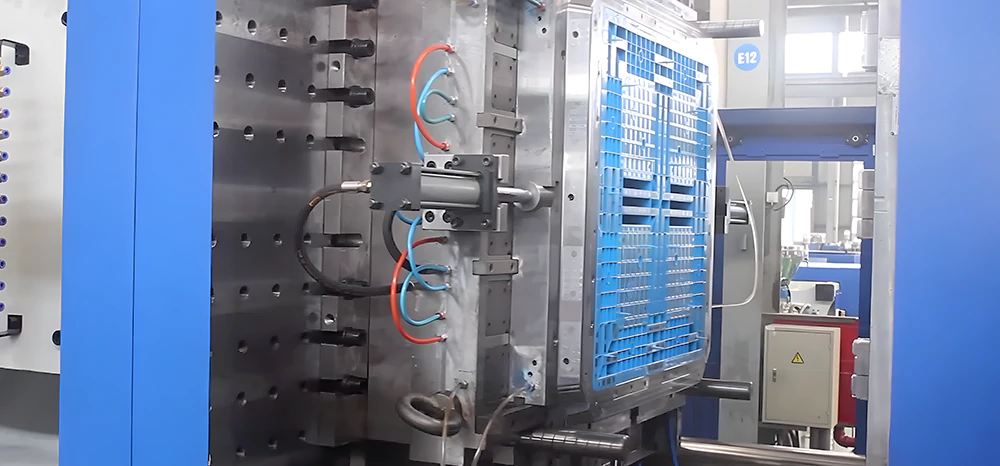

Faster Mold Changing Speed

One of the standout features, as exemplified in machines like CLF’s TPII Injection Molding Machine, is the accelerated mold-changing process. This is a game-changer for manufacturers involved in small-volume, large-variety production scenarios.

The specifically designed structures facilitate quicker and smoother transitions between molds, minimizing downtime and maximizing overall production efficiency.

Flexibility of Customization

The two-plate design incorporated in plastic molding for plastic pallet machines introduces a new level of flexibility for customization. Take, for instance, the TPII series, allowing mold exchange from the side.

This provides additional space and simplifies the process, making it an attractive investment for plastic pallet manufacturers aiming for distinctive designs. The flexibility offered in customization ensures that each plastic pallet can be tailored precisely to meet diverse industry needs.

A successful example is the collaboration of a prominent Taiwanese brand specializing in plastic pallets. By refining the cooling system design and strategically reducing product cycle time, there was a remarkable 40% decrease in overall cycle time.

This translated into an impressive feat – the production of an 11 kg plastic pallet in a mere 90 seconds. This success story underlines how advancements in plastic pallet injection molding can lead to significant improvements in production efficiency and output.

The Plastic Pallet Injection Molding Process

The plastic pallet manufacturing process through injection molding involves several crucial phases:

Precise Material Input

The journey begins with the introduction of plastic into the injection molding machine through a meticulously controlled hopper system. This step ensures precision in material input, laying the foundation for creating high-quality injection-molded plastic pallets.

Melting and Injection

The plastic material undergoes a transformative process involving heating bands and friction force, resulting in its transition to a liquid state. This molten plastic is then injected into a carefully crafted mold or cavity, taking on the precise shape required for the plastic pallet. Efficient cooling and hardening follow suit, facilitated by a state-of-the-art refrigeration system.

Types of Injection Systems

In the realm of plastic pallet manufacturing, two primary injection systems play a crucial role:

- Low-Pressure System: This system involves injecting the mold cavity with a blend of plastic material and an inert gas. The outcome is a cellular core enveloped by rigid plastic. This method proves ideal for crafting plastic pallets with an optimal strength-to-weight ratio, ensuring both durability and cost-effectiveness in production.

- High-Pressure Injection: Widely employed in the manufacture of high-density polyethylene (HDPE) or polypropylene (PP) plastic pallets, the high-pressure injection system is a precise method known for delivering a high gloss finish to the final product. Notably, this eliminates the need for additional post-production treatments, streamlining the manufacturing process.

Thermoforming Plastic Pallets

The thermoforming process is another prominent injection-molded plastic pallet manufacturing process, particularly suitable for large-scale production. The process involves heating plastic to a pliable temperature, forming it over a mold, and allowing it to cool. The thermoforming process offers two main techniques: vacuum thermoforming and pressure thermoforming.

Blow Molding Plastic Pallets

Blow molding, focusing on forming hollow parts, is a distinctive process that produces plastic pallets with excellent resistance to low temperatures. It involves melting plastic material, forming a parison, clamping it into a mold, and inflating it with compressed air. Blow-molded plastic pallets are known for their durability and impact resistance.

Choosing the Right Manufacturing Process

Selecting the most suitable injection molded plastic pallet manufacturing process involves evaluating various factors:

- Quality of the Plastic Pallet: Different processes yield varying qualities; choose based on the desired characteristics.

- Cost Considerations: Assess tooling, equipment, labor, and energy costs to align with budget constraints.

- Production Capacity: Opt for a process that meets production demands and offers scalability.

- Surface Finish and Design Tolerance: Consider the aesthetic and functional requirements of the injection molded plastic pallets design.

Tips for Designing Plastic Pallets Using Plastic Molding

Intricate and Customized Pallet Designs

Innovative design is a crucial benefit of plastic molding for the production of plastic pallets because this technology allows creating complex and customizable patterns that meet special needs. Plastic molding for plastic pallets enables precise shaping of size, structure, and features, allowing for versatility in handling different loads.

Whether it’s delicate items requiring special care or heavy loads demanding stability, plastic-molded pallets offer a tailored solution for diverse applications. This customization enhances efficiency in material handling practices across various industries.

Durable and Resistant to Wear and Tear

Injection molded plastic pallets manufactured through molding processes exhibit remarkable toughness, withstanding extensive wear and tear inherent in industries like warehouses and logistics. These pallets prove resilient in challenging conditions, such as exposure to moisture and chemicals, making them more durable than traditional wooden pallets. Their ability to endure heavy loads without deformation or damage ensures a longer lifespan, contributing to cost savings and sustainability.

Consistent, Precise, and Uniform Dimensions and Weight

The plastic molding process ensures a high level of consistency and precision in the dimensions and weight of injection molded plastic pallets. This uniformity is crucial in industries like food and beverage, pharmaceuticals, and retail, where efficient stacking, storage, and transportation rely on standardized pallet sizes.

Additionally, the overall quality, durability, and resistance to impact remain consistent across all pallets produced through molding, meeting the demands of rigorous conditions.

Cheaper Shipping Costs

Plastic-molded pallets possess a significant advantage in terms of weight, as they are lighter compared to their wooden counterparts. The reduced weight contributes to more efficient transportation, leading to cost savings in shipping.

The lighter pallets are more convenient to maneuver thus decreasing the impact on workers and lessening injuries tied with heavy lifting. Moreover, the absence of splintering eliminates the risk of product damage during transit, further enhancing the cost-effectiveness of plastic-molded pallets.

Make the Pallets Non-Porous and Easy to Clean

Plastic-molded pallets, by design, are non-porous, lacking tiny gaps that might absorb liquids, odors, or contaminants. This property ensures that they are suitable for use in industries, where hygiene is essential as food and pharmaceutical sector.

The non-porous nature of these pallets prevents propagation of bacteria, molds or other pathogens, ensuring a clean and safe work environment. Additionally, the smooth and seamless surfaces simplify the cleaning process, allowing for easy removal of dirt, dust, or spills through various cleaning methods.

A Comprehensive Guide to Making a Plastic Pallet Mold in 5 Easy Steps

Step 1: Product Design of Plastic Pallets

In the initial phase, thoroughly understand the specific requirements of the plastic pallet. Consider factors such as intended use, load-bearing capacity, and industry standards. Ensure that the finished product meets all standards and specifications by addressing potential problems with molding procedures.

Step 2: Plastic Pallet Mold Gate Design

When designing the plastic pallet mold gate, use CAE tools to analyze the multi-point gate design for potential defects. Optimize the gate design to avoid excess weight issues during transport. Additionally, consider using integral hot runners to evaluate their effectiveness in reducing material leakage and ensuring an efficient material flow during molding.

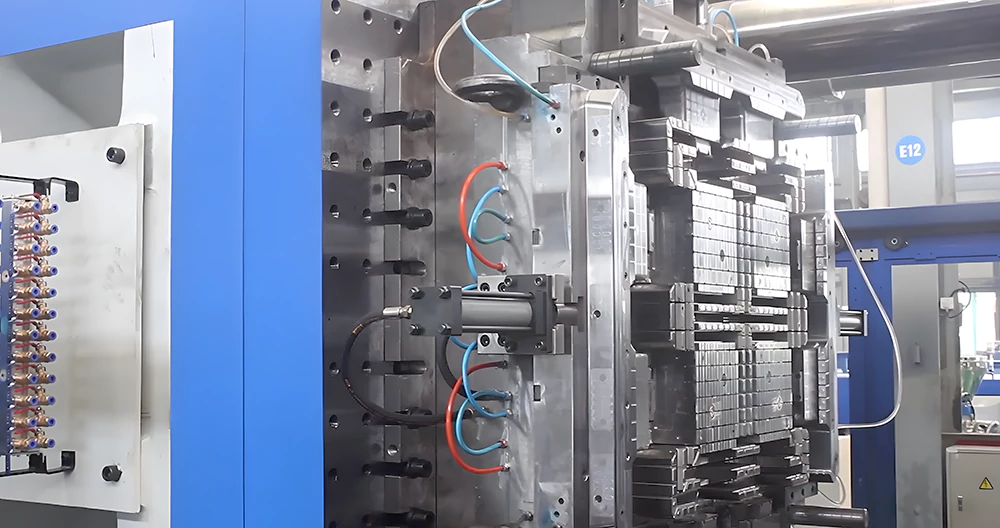

Step 3: Designs for Plastic Pallet Mould Inserts and Inserts Waterway

Focus on designing molds with high-precision inserts for both moving and fixed mold parts. Utilize CAD software for detailed and precise insert designs. Ensure even material flow through each section by designing an efficient waterway system within the inserts. Optimize the cooling system to prevent heat-related shifting during the molding process.

Step 4: The Ejection Design of the Pallet Mold

Incorporate a large number of ejector pins into the design, strategically placing them based on the product structure. Choose ejection positions with good structural support for smooth and efficient ejection. Select high-quality pin accessories that fit smoothly with the insert, and connect enough rods from the plastic machine to provide even force and minimize deformation during the ejection process.

Step 5: Selection of Pallet Mold Steel

Evaluate steel hardness, toughness, and processing costs based on mold requirements. Verify the correctness of the ordered steel before fabrication to ensure structural integrity. Before fabrication, ensure the selected steel meets the criteria for successful mold fabrication.

Conclusion

As the demand for injection molded plastic pallets grows, manufacturers face the challenge of optimizing production efficiency and sustainability. Plastic molding, especially injection molding and thermoforming process, emerges as a key solution, offering a balance between cost-effectiveness, customization, and environmental considerations.

Note: For expert CNC manufacturing and injection molding services, Prototool stands out as an industry leader, providing comprehensive solutions for plastic pallet production.