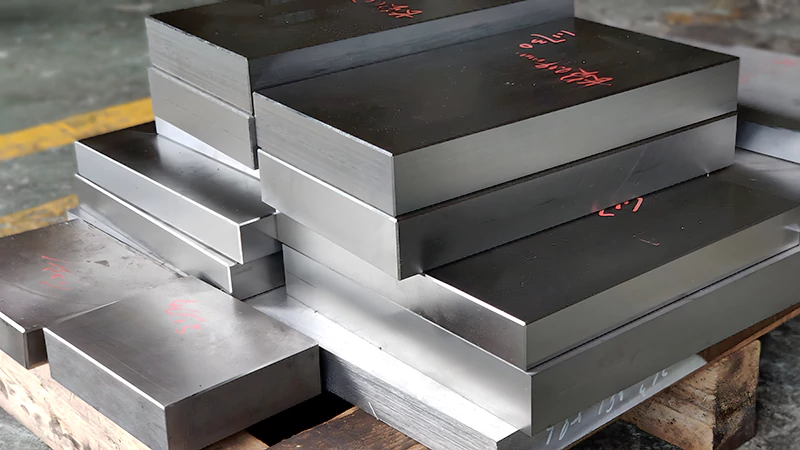

Stainless steel is now one of the most widely utilized machining materials. From everyday products to cutting-edge tools, stainless steel machining is at the heart of it all. Unlike working with wood or softer materials like ABS, mastering stainless steel machining requires unique skills.

This durable alloy boasts high hardness and tensile strength, demanding a grasp of specialized stainless steel metalworking techniques. In this article, we’ll take you through the world of machining stainless steel, exploring its different grades, unveiling the best tools to shape it, and sharing additional insights to help you navigate stainless steel machining.

Before we dive right in, don’t forget to check out our detailed guide on Bearbeitungsteils to get a better know-how of the present-day machining process.

What is Stainless Steel?

The two main parts of stainless steel are iron and chromium. Sometimes, manufacturers add materials like carbon during stainless steel manufacturing to make it better for certain jobs. However, chromium is the key ingredient in stainless steel, which fights rust and damage like a superhero.

Iron, however, is great because it is very tough. But it also comes with a loophole- being rusty and scratched up easily. This is where chromium comes into play. Simply put, when chromium is added to iron, it makes stainless steel resistant to rust and scratches.

It’s like putting on a cover that keeps the metal looking nice and strong for a long time. This ideally defines the structural properties of stainless steel.

Can Stainless Steel Be Machined?

To begin with the most basic inquiry, you may wonder if stainless steel can be machined. Yes, it certainly can. There are numerous methods for machining stainless steel. Moreover, it can be very simple once you understand its qualities and the necessary machining procedures to utilize during stainless steel machining.

Properties of Stainless Steel

Stainless steel is like the superhero of metals in not getting rusty. It’s made special by having a lot of something called “chromium,” which makes it super good at resisting rust and damage.

Regarding classification, stainless steel elegantly falls into five distinct categories: Austenitic, Ferritic, Martensitic, Precipitation Hardened (PH)und Duplex. Each category unveils a fundamental, versatile alloy, serving as a canvas for tailored modifications that birth specific traits for diverse applications.

To show how different they are, here is a look at the properties of each category, along with a few famous stainless steel grades that fall into these categories:

| Kategorie | Properties | Popular Grades |

| Austenitic | It is non-magnetic while having exceptional resistance to corrosion and heat. | 304 and 316 |

| Ferritic | It is magnetic and has a lower corrosion and heat resistance than Austenitic stainless steel. | 430 and 446 |

| Precipitation Hardened (PH) | This is the toughest grade of stainless steel that can handle heat treatment. It is also highly resistant to severe corrosion. | 17-4 PH and 15-5 PH |

| Duplex | This type of stainless steel is a stronger mixture of Austenitic and Ferritic stainless steel. | 244, 2304 and 2507 |

| Martensitic | It is magnetic with medium resistance to corrosion, but it’s not suitable for heavy corrosion environments | 416, 420 and 440 |

How to Select the Right Stainless Steel for Machining?

Choosing the right stainless steel for your machining needs involves considering several important factors. Stainless steels were initially used in applications like gun barrels, cutlery, and nitric acid tanks. Over time, more compositions were developed to meet specific requirements, such as better corrosion resistance, higher strength, and heat resistance.

For instance, Type 304, a commonly used stainless steel, has variations like Type 316, chosen for its greater corrosion resistance in marine settings. Type 305 is better for cold forming, while Type 303 is the more machinable version of Type 304.

Five key criteria should be evaluated to pick the best stainless steel, listed below by priority:

- Corrosion or Heat Resistance: This is the primary reason for choosing stainless steel. Consider the environment and the level of corrosion or heat resistance needed.

- Mechanical Properties: Pay attention to strength at different temperatures. The balance between corrosion resistance and strength guides selection.

- Fabrication Operations: Consider how the product will be made, including machining, forming, and welding. The most challenging operation usually takes precedence.

- Total Cost: Look at the big picture, considering the material, production costs, and long-term benefits of a durable product.

- Availability: Determine if the material is readily available by contacting steel service centers or mills.

While the main focus is on meeting end-use needs, don’t overlook the stainless steel manufacturing aspect, particularly machining.

Specifically, It’s crucial to keep in mind that stainless steels are special kinds of metal blends that have at least 10.5% chromium along with iron. Moreover, other elements like nickel, molybdenum, columbium, or titanium are potentially added to it during melting to enhance specific properties. Considering these aspects, you can confidently select the right stainless steel for your machining projects.

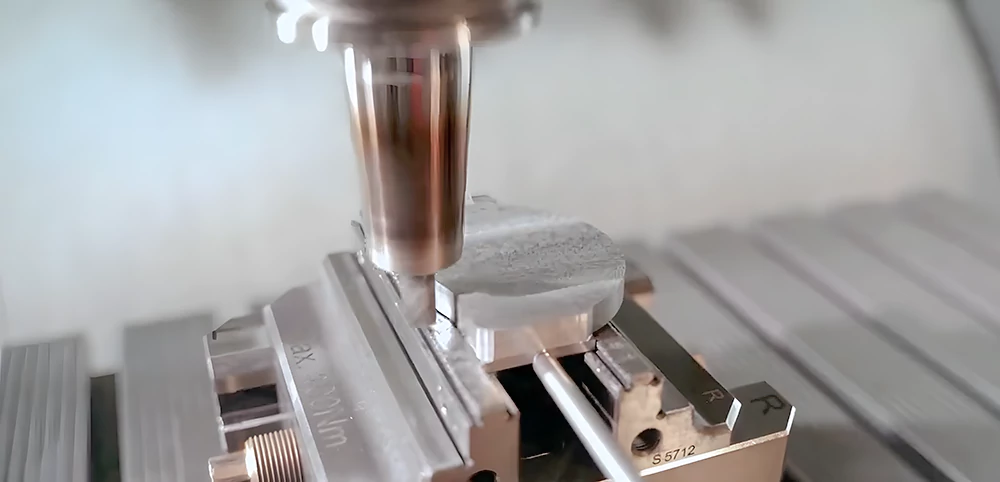

Tools for Machining Stainless Steel

Understanding the tools for working with stainless steel is essential for successful machining. Whether you’re shaping, smoothing, or creating slots, the right tool selection is key. Let’s explore the various tools and techniques for machining stainless steel:

Traditional Roughing

For classic roughing, using a four or 5-flute end mill is recommended. While five-flute tools allow faster feed rates, four and 5-flute styles are great for roughing.

Slotting

Efficiently removing chips during slotting is important. Opt for four flute tools for better chip evacuation. Tools with chip breaker geometry work well for slotting stainless steel as they clear away smaller chips more effectively.

Fertigstellung

To achieve polished stainless steel parts, go for end mills with a high flute count and a helix angle over 40 degrees. Finishing end mills with five or more flutes are ideal. For more aggressive finishing, consider end mills with 7 to 14 flutes.

High-Efficiency Milling

High-efficiency milling (HEM) is great for stainless steel, especially with the right tools. Chipbreaker roughers, available in 5 or 7 flute styles, are an excellent choice for stainless steel milling. Standard 5-7 flute variable pitch end mills also work well for HEM toolpaths.

HEV-5

One versatile tool for stainless steel is the HEV-5 end mill by Helical Solutions (Check Spiralfräsen). It’s fantastic for finishing, HEM toolpaths, slotting, and roughing. Available in square, corner radius, and long reach styles, the HEV-5 is a well-rounded choice for your tool collection, optimizing it for stainless steel machining.

Difference Between 304 and 316 Stainless Steel

When machining stainless steel, understanding the differences between grades is essential. Let’s delve into the distinctions between 304 and 316 stainless steel:

304 Stainless Steel

- Also known as A2 stainless steel.

- Contains 18-20% chromium and 8-10% nickel.

- Economical and easier to fabricate.

- Widely used in wheel covers, electrical enclosures, and general steel pipes.

- It is notable for its strength, making it stronger than “mild” steel.

- Less heat-sensitive than grade 302 steel.

- It is resistant to most oxidizing acids, which makes it suitable for easy sanitization.

- Often used in food processing equipment and hot water systems.

- Generally, it does not have any special marking to distinguish it.

316 Stainless Steel

- Also called A4 stainless steel.

- Contains 16% chromium, 10% nickel, and 2-3% molybdenum.

- Renowned as marine-grade stainless steel due to its molybdenum content.

- Highly corrosion-resistant, particularly against chlorides found in seawater and de-icing salts.

- Suitable for marine environments, floating oil rigs, and oil refinery piping.

- More chemically resistant, withstanding fatty acids and sulfuric acid at high temperatures.

- Can endure temperatures up to 1600°F (871°C).

- Typically marked with a six inside a circle for identification.

In summary, the presence of molybdenum sets grade 316 stainless steel apart from 304. This inclusion enhances its corrosion resistance, making it an ideal choice for marine applications and chemically challenging environments.

While 304 stainless steel is economically advantageous and widely used, 316 stainless steel is robust against corrosion and various chemicals. Remember, even though these grades look the same, a material test report is often necessary to discern the difference, as only items made of 316 stainless steel may carry the distinct marking.

What Makes Some Types of Stainless Steel Easier to Machine Than Others?

The ingredients are the key to knowing how to work with stainless steel. So, you can see that each type of stainless steel has its own mix of minerals. But here’s the catch: not all stainless steels are the same regarding how easy they are to work with.

Let’s compare these two things. Take steel of grade 316 and its close relative, 316B. With a machinability value of 60, grade 316 is good for stainless steel component machining. 316B has a grade of 50 and is harder to work with. It’s like comparing two cars with slightly different gas mileage: one gets a little farther on the same amount of gas.

Now, let’s meet grades 304 and 304L. These two are like brothers and sisters because they are both good at making things. They are both 70 on the machinability scale. They have the same talent for being shaped and cut into different parts.

But there is a big star in the world of stainless steel: Alloy 303. With an AISI machinability grade of 150, this one is very easy to work on. To give you an idea of what this means, the normal grade for machinability is 100. So, Alloy 303 is like the student in the machining class who does too much and makes the job look very easy.

Ultimately, working with stainless steel is like working with different recipes. Some kinds are easy to machine, while others might take more work. It all comes down to how their ingredients are put together and how they have been tweaked to do specific jobs.

Wrapping Up!

Stainless steel is a top pick for many industries, especially for making tough machine parts that don’t easily corrode. If you plan to use stainless steel for your next project, feel free to connect with our professionals at Prototool. Get a quote for stainless steel machining today!