When ejector pins in injection molding were introduced to industrial processes, it sped up production, automated procedures, and produced higher-quality goods. Additionally, it has helped make product designs more uniform. The injection molding method still has many issues that need to be fixed, like ejector pin marks, even though it has improved manufacturing procedures. This will ensure that the final products are superior and more potent. As a result, this article explores ejector pins 101 and how to improve its design for better-performing goods.

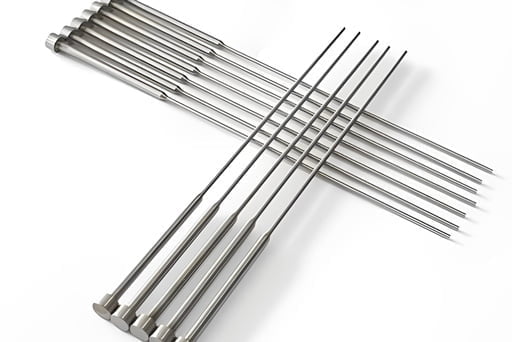

Ejector Pin for Injection Molding: What Is It?

Injection mold ejector pins are essential while making components. These are a crucial part of the injection molding process’s ejection system in the mold, which decides how the finished goods will turn out.

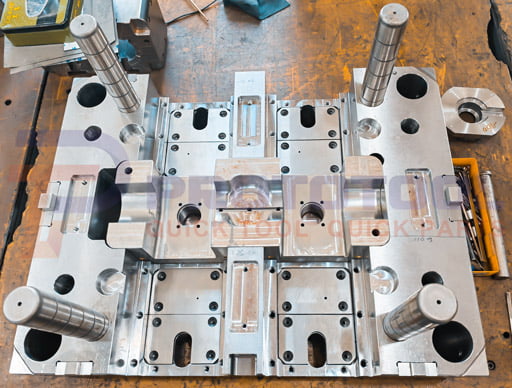

A metal mold is injected with molten plastic to take the shape of the mold during the manufacturing process, known as injection molding. As a result, ejector pins entail removing finished pieces from dying molds. The A and B sides make up the two components of the metal mold. Both halves of the metal mold are split apart when the molten substance in the mold has cooled, enabling the solid plastic to be removed. The design of an injection mold allows the A-side half to be lifted when it is opened, leaving the formed portion and the B-side.

The ejector pin marks that force the produced part out of the mold are situated on the B-side portion of the mold. Finished products frequently have a dent left behind by the pin mark of an ejector mold.

Different Ejector Pin Styles:

The quality of the ejection mechanism in the injection mold’s construction directly impacts the finished plastic product’s quality. A poor design will result in several flaws, like ejector pin marks in injection molding in the plastic part, including cracks, warping distortion, and whitening of the plastic part. The most crucial link in the ejection design is choosing the appropriate ejection type. We usually use the ejection force and resistance to maximize the ejection type, number, and position. The sorts you’ll discover most frequently suitable for the process are listed below.

Ejector pin in black:

Nitride H13 pins cannot be used in working temperatures beyond 600°C, which is why manufacturers created these ejector pins. The black ejector pin has a black coating on its surface, making it self-lubricating and able to resist temperatures of up to 1000°C. It is a pricey ejector pin that can be used with a metal ejection mechanism in car molds.

Pins for through-hard ejectors:

Heat treatment is used on these injection mold ejector pins to maintain uniform hardness across the pin’s diameter. The majority of through-hard pin applications are for the plastic ejection system in molds because they can tolerate operating temperatures of up to 200°C.

Ejector pin with case hardening:

They are much tougher pins than the through-hard pins and are appropriate for die-casting ejection systems in molds. Also, they are known as Nitride H13 pins. Nitrated to 65–70 HRC, case-hardened pins can endure temperatures of more than 200°C.

Design Considerations For Injection Molding:

The design of an injection mold must ensure that it performs as expected. A design flaw might cause a part to break or to have injection molding ejector pin marks, which would be too expensive or difficult to fix. Therefore, it is crucial to implement a well-structured design, and there are a few things to think about.

Equal wall thickness:

Molten material flows readily and without resistance when poured into a mold with uniform wall thickness, filling the cavity of the wall and taking on the mold’s predetermined shape. The thinner portion of the molten material will cool as a result of the mold walls’ unevenness. As a result, the material will shrink as the thicker piece cools, causing tension to concentrate and finally leading to cracking when the section is removed.

The problem can be fixed by coring and inserting gussets, though, if your design does not permit uniform wall thickness. To maintain consistency along the wall, the molten plastic is removed from a large area using a technique called coring. Gussets are reinforcements that you place on the wall as support structures to thin out the wall.

The type of substance:

The product’s intended usage should determine the kind of material that is employed. Thickness, flexibility, and hardness are all different types of materials. The intended use of the component and its design would depend on the material type selected. Certain materials can be curved into shapes in addition to being able to be thickened. Additionally, before selecting the sort of material, you should think about these.

Establish draft angles:

An injection mold‘s two sides might have a slant added to them called a draft angle. The plastic may be easily removed from the mold because of this tiny distortion in the mold’s shape. When extracting the item from the mold, a draft mold has to be present to provide friction resistance.

The easy release of pieces from the in-mold ejection system would be ensured by allowing more draft angles. A lack of draft angles would cause the item to be removed with significant ejector pin marks, as well as scrapes on the mold wall.

Locations of the gates:

The entrance sites for the molten plastic into the mold are called injection molding gates. A gate, however, leaves a pin mark as the item cools, and this pin mark is frequently still noticeable even after the dent has been removed. The design team can use an edge gate to solve this problem, making the dents that occur less obvious. The extension on the ejection pin allows for the injection of the molten substance as well. After cooling, the ejector pins may push the pin mark that forms on the gate when the item is removed from the mold after cooling.

Undercuts should be minimized:

In the design of the mold, undercuts are protruding elements that prevent either side from being removed. Since they prohibit direct part ejection from the mold, undercuts are a required and unavoidable part of mold design.

The creation of interlocks or latches that permit simple removal or assembly, however, can eliminate undercuts. Fewer amounts of undercuts in a mold-based ejection system are required to the best of the design team’s ability.

Aim for round edges:

There are many benefits to having rounded corners on both the inside and outside of the part. It lessens the area of concentrated stress and keeps the component from shattering. Sharp edges prevent molten plastic from flowing freely through the die, and when the plastic cools, it pulls up against the edges and is challenging to remove. The formation and removal of goods are improved and easier with round-edged pieces, which are also more affordable to create.

Popular Errors and Fixes:

There are some flaws in injection molding that uses ejector pins. The potential flaws and the necessary fixes are listed below.

- Ejector pin marks:

The “dents” are ejector pin marks caused when removing the item from the mold. This pin mark may cause the products to break while being used. As a result, it’s critical to design an ejection system into the mold to avoid ejector pin markings.

- Injection mold ejector pins should be positioned so that the force of ejection is continuous throughout the portion.

- To prevent ejector pin marks defect, place the ejector pins on hard components like metal inserts, pillars, and ribs.

Instead of placing the ejector pins on slopes, design the portion with flat surfaces.

- Breaks:

Ejector pins frequently break because there is a mismatch between the force needed to eject the part from the mold and the pin’s strength. It takes force to expel the components from the mold. Sometimes the length of the pin, which is not supported, causes the required force to be greater than the pin’s strength, resulting in breakage.

The use of more ejector pins with bigger diameters is, therefore, the most effective treatment for ejector pin breaks. By doing this, the force needed is distributed evenly across all of the pins, which lowers the likelihood of breaking.

- Jetting:

When molten material is injected into a mould quickly or with a small gate size, jetting—which causes the shape to be distorted—occurs. Remedying this entails:

- Increasing the gate’s size and regulating how the molten material flows into the mold.

Conclusion

Ejector pins play a crucial role in the injection molding process, which design experts cannot overlook. It is so that ejector pin marks and other flaws are avoided, which is important for the created product in the mold. As a result, it’s critical to put your trust in a business that understands Design for Manufacturing, understands how to employ ejector pins, and has a proven track record of handling ejector pins injection molding design.

For the injection molding of your ejector pins, Prototool can ensure optimum designs. For manufacturing guidance, speak with their support staff, as they will go above and beyond to ensure you have a positive and dependable experience using their services.