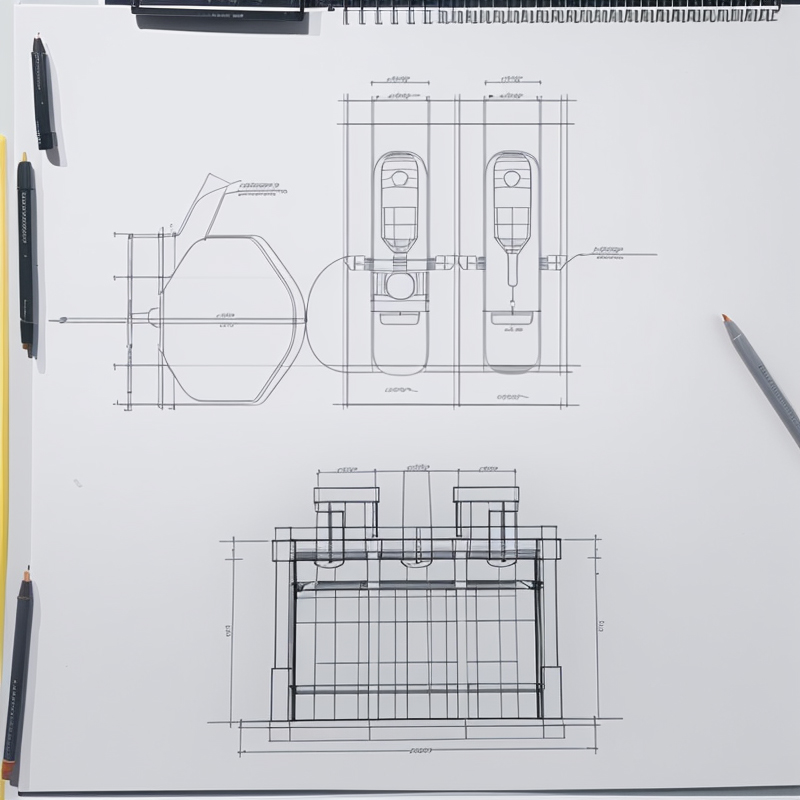

ボスのデザイン主要要素、設計ガイドライン、よくある問題と解決策

射出成形におけるボス設計を理解し、プラスチック成形部品の重要な要素、設計指針、解決策に焦点を当てる。

適切な素材で製品設計を成功させる戦略

美しい製品を作るための金型メーカーとのコラボレーションを中心に、製品デザインにおける素材選択の役割について説明しよう。

デザインにおけるブラインドホールとスルーホールを使いこなす

Explore blind holes and through holes from this guide specifically aimed at professionals aiming to improve your parts design skills.

医療機器の設計と製品開発における一般的なステップ

医療機器の設計と製品開発における重要な段階を発見し、品質と厳しい規制へのコンプライアンスを確保します。

プロトタイプのコストまたは価格に影響を与える要因

ラピッドプロトタイプのコストに影響する主な要因をご覧ください。ラピッドプロトタイプの価格を理解し、見積もるための簡潔なガイド。

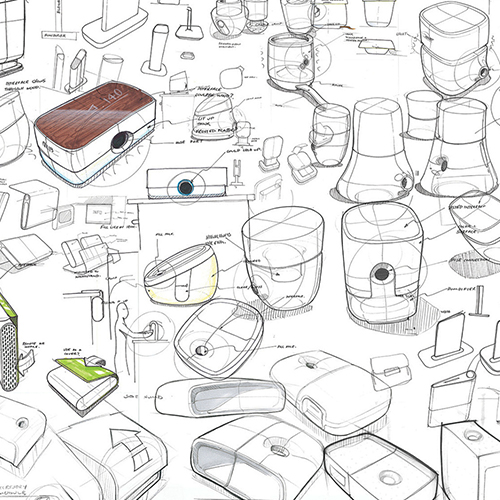

インダストリアル・デザインにおけるプロダクト・スタイリング・デザインのABC

インダストリアルデザインにおけるプロダクトスタイリングデザインの世界を探求してください。ユニークで機能的、そして審美的に魅力的な製品へと導きます。

初心者として、どの製品デザイン・ソフトウェアを選ぶべきか?

CAID、RhinoからCATIA、SolidWorksまで、製品設計ソフトウェアと、美的設計および構造設計におけるそれぞれのユニークな役割を比較します。

射出成形用プラスチック部品設計の一般原則

Experienced product designers deeply understand injection molding processes and consider numerous factors in plastic part design. This article focuses on essential elements such as wall thickness, draft angles, ribs, holes, pillars, snaps, interference fits, and tolerances in plastic molded part design. Wall Thickness In Plastic Parts Design Determining the appropriate wall thickness is crucial. Other features like ribs and fillets reference the wall thickness. The wall thickness of a plastic product depends on various requirements, including the external forces it must withstand, support for other parts, properties of the plastic material, weight, electrical performance, dimensional accuracy, stability, and assembly requirements. Typically, the wall thickness for thermoplastic materials ranges from 1 […]

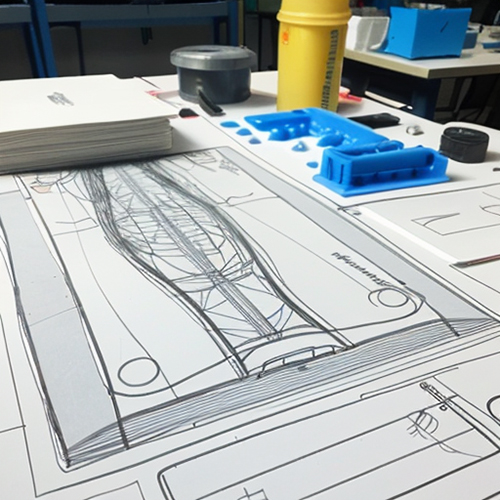

優れた製品構造設計に必要な基礎知識とは?

Product structural design refers to the process of designing the physical aspects of products, such as digital devices and home appliances, after their external appearance has been conceptualized. How to understand the definition of “Product Structural Design” This design phase bridges the gap between the aesthetic design and the manufacturing process. For instance, in the case of an electric egg beater, once the external design detailing its shape and color is finalized, the next step involves structural design. This includes using 3D modeling to incorporate internal components like the motor, circuits, and switches into the design. The process extends to dividing the outer shell into parts, creating molds for injection […]

成功する製品開発のステップ

アイデアの創出から発売後の評価まで、製品開発を成功させるためのステップを起業家や製品管理者向けに解説。