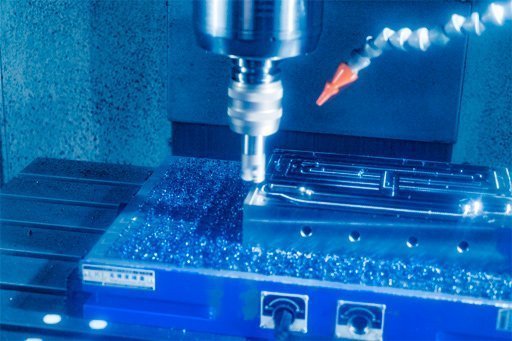

If you have been in contact with the CNC processing industry, you may have heard the words “milling” and “turning,” so what is milling? Milling refers to a high-efficiency processing method that can cut workpieces by the use of rotating multi-edge cutting tools. When working, the cutting tool rotates, and the workpiece is fixed. Milling is generally carried out on milling machines or boring machines, suitable for machining planes, grooves, various shaped surfaces (such as splines, gears, and threads), unique shapes of molds, etc.

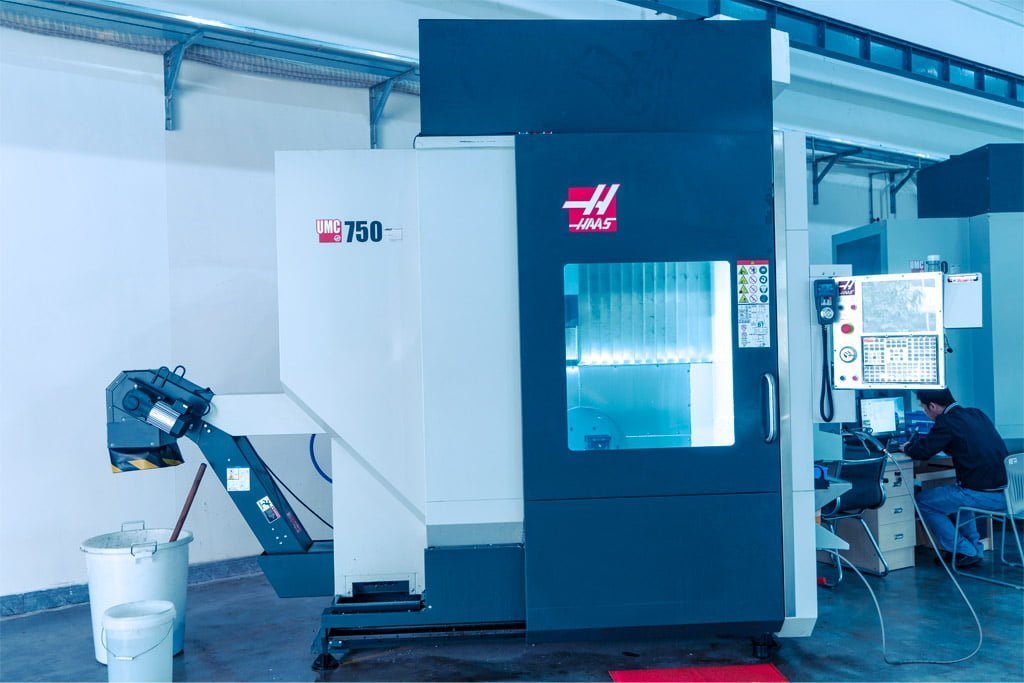

What Is a Milling Machine?

The most typical method of material cutting and boring is processing. A processing shaper is a rotating barrel-shaped device used by processing machines, whether operated manually or by CNC. Its size and structure can change and are held in a shaft. The main distinction between a processing machine and another boring machine is the ability to cut at different angles and move different tomahawks. Thus, there are a few different types of processing devices that are classified according to the number of development tomahawks:

The x- and z-tomahawks can have spaces and openings carved out using 2-axis processing equipment. When all is said and done, this machine will simply and uniformly chop (yet just in one course).

3-axis processing machines add the y-hub. This collection of processing equipment is the most well-known. Although you can cut upward and in any direction, a circle, for example, requires that each half be completed in turn. It is because cutting from below is unrealistic, even with three tomahawks.

Because they add the ability to turn the x-hub like a machine, 4-axis processing machines are more complex. Turn in the x- and y-tomahawks is consolidated by 5-axis processing equipment. The most comprehensive processing device available is this one. You may use it to mold bones, aircraft parts, car models, medical supplies, and anything else you can think of.

Although a PC operates them, CNC processing machines can have several tomahawks (between two and five). No manual labor is necessary.

Types of Milling Machines

Today, we understand that any processing machine run by a PC qualifies as a CNC machine. However, in other hub configurations, there are still a few different types of processing equipment, both manual and CNC:

Horizontal Mill: Although this processing device resembles an upward factory, in reality, the shaft is positioned equally, not upward. Even factories, though generally thought of as less versatile than vertical plants, are more suited to longer or heavier pieces of work. A large-scale plant has the additional capability of turning the z-hub on its head (making it a 4-axis processing machine).

Vertical Mill: This three-pivot processing device has an arm that connects the shaft to a table that serves as a work surface. The shaft is positioned upward and connected to the table and the arm in an upward segment. Typically, the table moves in all directions along the z-pivot to meet the fixed arm. However, the type of vertical factory determines how the table and shaft move in sync with one another. In a vertical turret plant, the table travels along the x- and y-tomahawks while the shaft is immobile. The table in a vertical bed factory must be moved along the x-pivot, whereas the shaft in the y-hub can follow the arm’s length.

Types of Milling Tools

There are many configurations of devices that perform different cuts for each machine. The device may be changed mid-work by a few more extensive, advanced devices. Selecting the best tool for the work is important because different apparatuses are designed for different materials. Failure to do so might result in unwanted damage to the material, the instrument, or both.

We should consider steel and wood: If you choose a tool made of steel that is too thick, you risk losing the piece of wood you were cutting. In the meantime, you will undoubtedly end up damaging the tool and the machine if you utilize wood tools made of steel. As previously said, the most important tool is a processing shaper, which resembles a bore but has teeth designed to remove material other than through entering. Cutters can fluctuate in size, form, and placement of their teeth.

CNC Milling Machine Operations

A CNC handling cycle is appropriate for delivering very accurate, highly flexible parts in a model, one-off, and small to medium production runs. Some handling machines can achieve up to more critical flexibilities than +/ – 0.0005 inches, even though parts are often transported with safeguards going from +/ – 0.001 inches to +/ – 0.005 inches. Due to the handling framework’s adaptability, it may be used for a variety of activities as well as for a variety of part features and plans, such as gaps, chamfers, strings, and pockets. The most popular CNC handling positions include:

- Structure processing

- Rakish processing

- Plain processing

The term “face processing” refers to operations in which the hub of rotation of the cutting tool is positioned in opposition to the workpiece’s outer layer. The cycle uses face processing cutters, which feature teeth on the device’s face and the edge. The edge teeth are primarily used for cutting, while the face teeth are used for finishing applications. Face processing is typically used to create level surfaces and contours on the finished object and is capable of producing more outstanding finishes than other processing techniques. This contact is supported by processing devices that are both vertical and even. Face processing includes side and end processing, which employs separate end and side cutters.

Plain Milling

The term “plain milling,” also known as “surface milling ” or “chunk milling,” refers to operations in which the exterior layer of the workpiece is lined up with the center of an upheaval of the mechanical cutting assembly. The cycle makes use of common processing cutters, which feature teeth that are sliced outward. Depending on the processing application’s requirements, such as the cut’s depth and the workpiece’s size, both narrow and broad cutters are used. More slender cutters are used to make more substantial cuts, whereas larger cutters are used to cut larger surface areas.

Suppose a straightforward processing application requires evacuating a lot of material from the workpiece. In that case, the manager first proposes a coarse-toothed shaper, moderate cutting speeds, and fast feed rates to give the unpleasant math to the hand-created thing. The overseer will then present a superior toothed shaper, quicker cutting velocities, and more slow feed rates to deliver the completed part’s subtleties.

Angular Milling

Rakish milling, also known as angular milling, refers to processing operations in which the pivot of revolution of the cutting apparatus is positioned relative to the outer layer of the workpiece. In order to produce accurate highlights like chamfers, serrations, and depressions, the cycle uses single-point processing cutters that are calculated in light of the particular plan being machined. The creation of dovetails, which makes use of 45°, 50°, 55°, or 60° dovetail cutters in consideration of the dovetail’s plan, is one typical use of precision milling.

Form Milling

Form milling refers to operations involving irregular forms, surfaces, and designs, such as components with fully bent or bent and level surfaces. The cycle makes use of fly cutters or framed processing cutters designed for a particular application, such as curved, recessed, and corner adjusting cutters. Creating hemispherical and semi-round depressions, dabs, and shapes, as well as many-sided plans and intricate elements, with a single machine setup, are a few examples of common uses for Form milling.

Other Milling Machine Operations

We can use processing machines to complete other machining and processing operations in addition to the ones already mentioned. Examples of the various processing machine tasks that are available include:

Straddle milling: “straddle milling” refers to operations where the machine device cuts at least two equally sized workpiece surfaces in a single pass. In this cycle, two cutters are used on a comparable machine arbor, arranged so they can process both sides of the workpiece concurrently, one on each side.

Gang milling: What is Gang milling? The term “Gang milling” refers to processing operations that make use of at least two cutters, typically with different sizes, shapes, or widths, on an identical machine arbor. Every shaper can perform the same cutting activity or one entirely different from it, leading to more erratic plans and intricate components being produced in a shorter time.

Why Is CNC Milling Important?

Numerous concerns are taken into consideration by modern breakthroughs and CNC processing equipment that can’t be solved swiftly by traditional methods. The innovation progresses in a more productive and compelling way to the working system. For instance, the most typical method of cutting metal for automotive or even aviation parts would be far less secure without CNC processing equipment. One can access and create high-quality designs that are easily converted into Cartesian directions with the aid of PC tools. Even interactivity helps to reduce prototyping costs!