What Causes Ejected Mark In Injection Molded Parts & How Can You Solve It?

People typically define ejector pin markings as glossy or white impressions on the surface of an injection-molded object. These markings exhibit various levels of glossiness, including dark or shadow-like impressions without any convex or concave features. People can observe these markings directly opposite the ejector pin location. This detailed guide will explore the cause and […]

Identifying and Correcting Short Shots – A Common Problem Faced During Injection Molding

Are you a professional working in the manufacturing industry? Or do you plan to enter the injection molding manufacturing sector as a skilled machine operator? Either way, understanding the injection molding process and the common issues that may occur, including short shots, is crucial. Now injection molding is a highly popular manufacturing process. However, despite […]

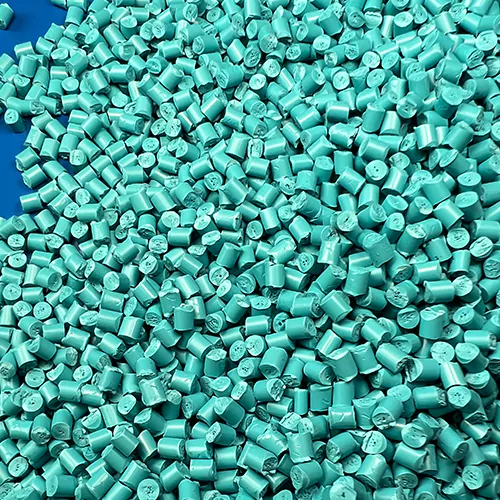

How to Manage the Color Difference Of Injection Molded Parts

In general, chromatic aberration is a prevalent fault in plastic injection molding. And it is found in the injection molding process. But that’s not all the defects that may occur in such parts related to their color differences. As we all know, several factors influence the color difference of finished injection molded parts. It’s no […]

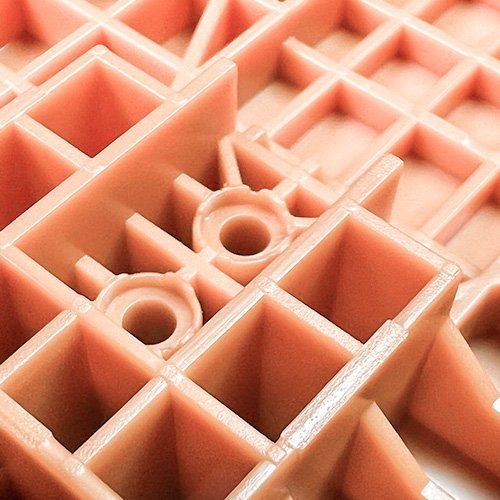

Injection Molding Defects: The Most Complete Types And Solutions

Are you concerned that you might overlook some of the most common injection molding defects during production? One of the most beneficial approaches to producing components is injection molding. Some advantages are high productivity, rapid production, adaptability to different sizes and shapes, and automated procedures. What’s more, the dimensions of injection-molded goods are often consistent. […]

Injection Molding Flash: Causes & Solutions And How To Avoid

Flash is one of the most often occurring defects in injection molding. The thin layer of plastic forms when two different mold surfaces meet to create a boundary. There may be a difference in growth and other characteristics at these locations, which may enhance the risk of a flash. Managing flash from injection molding is […]

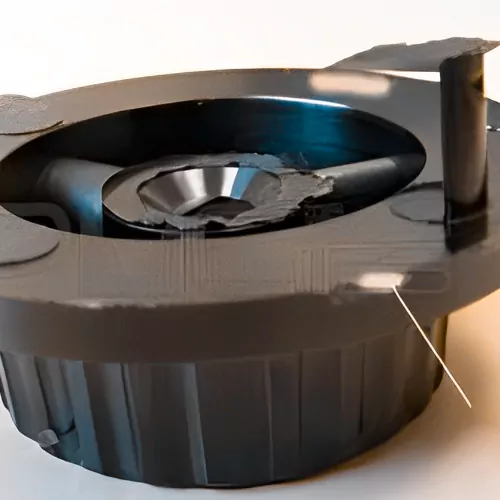

Sink Mark in Injection Molding: Reasons And Solutions

A sink mark is a typical injection molding flaw that can appear in the thicker dimensions of a molded part or object. Thankfully, with the right ways, you can prevent the sink mark from occurring in the injection molded parts. Now, if you’re new to exploring sink marks and how to avoid sink marks in […]