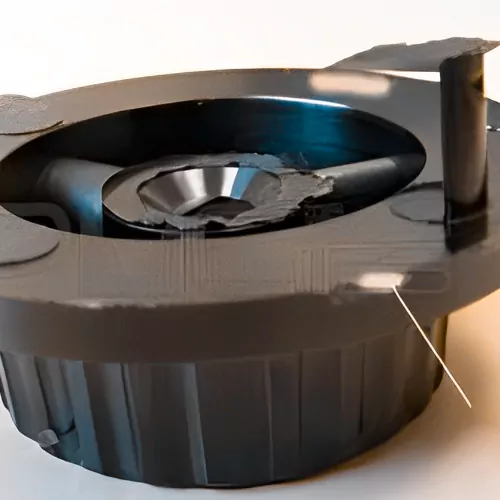

射出成形部品における突き出し痕の原因と解決方法

People typically define ejector pin markings as glossy or white impressions on the surface of an injection-molded object. These markings exhibit various levels of glossiness, including dark or shadow-like impressions without any convex or concave features. People can observe these markings directly opposite the ejector pin location. This detailed guide will explore the cause and solutions of ejected marks. What is an Ejected Mark? An ejected mark, also known as an ejection mark or ejector mark, is a common issue that can occur on injection molded products. It refers to a visible indentation, depression, or blemish on the surface of a molded part caused by the ejection process. During injection […]

Identifying and Correcting Short Shots – A Common Problem Faced During Injection Molding

Are you a professional working in the manufacturing industry? Or do you plan to enter the injection molding manufacturing sector as a skilled machine operator? Either way, understanding the injection molding process and the common issues that may occur, including short shots, is crucial. Now injection molding is a highly popular manufacturing process. However, despite its widespread use and popularity, injection molding has challenges. One common issue in injection molding is a short shot, which can significantly impact the quality of the final product. And as a skilled professional operating an injection molding machine, you need to know what causes short shots in injection molding and how to fix short […]

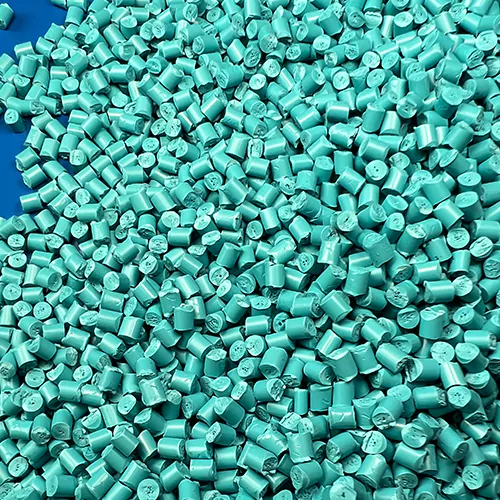

How to Manage the Color Difference Of Injection Molded Parts

In general, chromatic aberration is a prevalent fault in plastic injection molding. And it is found in the injection molding process. But that’s not all the defects that may occur in such parts related to their color differences. As we all know, several factors influence the color difference of finished injection molded parts. It’s no surprise that it’s one of injection molding’s most difficult-to-control technologies. Professional service providers, such as Prototool, understand the types of errors and how to avoid them to supply customers with high-quality injection molded parts. Please continue reading to learn how such businesses do it. How Are Colors Mixed in Injection Molded Parts? · Compounding In this […]

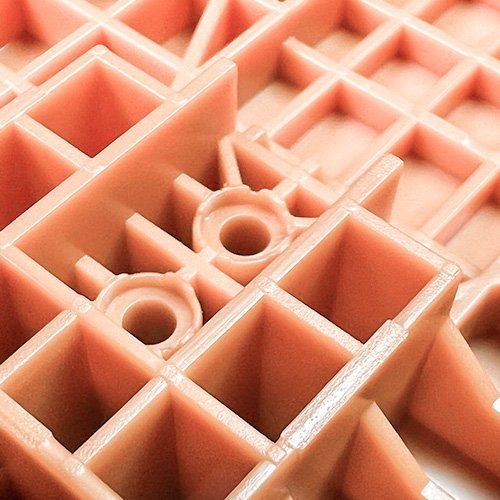

射出成形の欠陥:最も完全な種類と解決策

Are you concerned that you might overlook some of the most common injection molding defects during production? One of the most beneficial approaches to producing components is injection molding. Some advantages are high productivity, rapid production, adaptability to different sizes and shapes, and automated procedures. What’s more, the dimensions of injection-molded goods are often consistent. However, several injection molding flaws still endanger product quality. This article will shed light on the numerous injection molding part flaws and the factors contributing to their occurrence. It also clarifies the many solutions you can practice to prevent these injection molding defects from affecting the product’s quality. Most Common Injection Molding Defects: 1. Burn […]

Injection Molding Flash: Causes & Solutions And How To Avoid

Flash is one of the most often occurring defects in injection molding. The thin layer of plastic forms when two different mold surfaces meet to create a boundary. There may be a difference in growth and other characteristics at these locations, which may enhance the risk of a flash. Managing flash from injection molding is a simple procedure, but it needs additional resources and reduces the overall efficiency of the process. In addition, Injection molding flash removal, which is the process of eliminating flash manually or mechanically, may have a detrimental effect on the product’s quality and may cause damage to the mold, which may result in additional costs and […]

射出成形におけるヒケ:理由と解決策

ヒケは射出成形の典型的な欠陥で、成形部品や成形品の厚い寸法に現れることがある。ありがたいことに、正しい方法で射出成形部品にヒケが発生するのを防ぐことができます。射出成形におけるヒケやヒケを防ぐ方法について初めて知る方は、以下でヒケについて詳しく説明しましょう。ヒケとは?初心者の方や射出成形に慣れていない方にとって、ヒケや射出成形品のヒケの原因はよくわからないかもしれません。しかし、ヒケのある成形品を使用することは、他の製造や [...] 続きを読む