Injection molding companies, which employ injection molding, spend a lot of time and energy developing the final product. Although these resources are expensive, the returns are worthwhile. Because the plastic mold design determines the shape of the finished product, molds are crucial to the manufacturing process. Different materials are potentially used in this mold-making process and for conducting injection molding thoroughly.

Moreover, since the injection mold-making technique enables inexpensive mass production of things in a reduced time, it accounts for the vast majority of plastics created today. It’s a cyclical procedure wherein new molds are used anytime old ones are worn out or no longer suitable for making the desired shape.

But what do these molds primarily do, how are they made, and what is the material often used to design the plastic mold? This detailed guide will tell you everything and much more. So keep reading!

What is Plastic Mold Design?

A plastic mold design or design molding plastic is a process in which the plastic injection mold is designed and produced for further usage. This plastic injection mold design, as manufactured, allows the production of products in the same design or shape as the mold. To successfully conduct this process, companies hire skilled designers and engineers to design and build the mold.

To what extent a molding process is fruitful and whether or not the final product has flaws depends on the state of the mold used in the process. Several things must be thought about before a mold can is made. Let’s explore some crucial aspects that should be considered before you move to the injection molding mold design production phase.

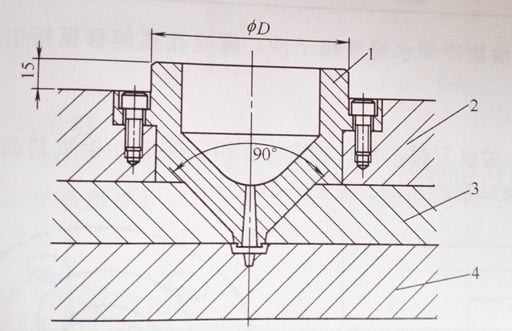

- Sprues: When using sprues, the orifice of the sprue must always be greater than the nozzle’s to avoid leaks.

- Steel: Steel (either hardened or pre-hardened), beryllium-core alloy, and aluminum are commonly used as mold materials. The cost of different mold materials must be considered. Speaking of which, steel construction is more expensive but will last the longest. Yet, steel’s long lifespan and low replacement cost make it a cost-effective material. The choice of steel also depends on the customer’s requirements.

Tips: Learn more about the lifespan of a mold. Please click to understand the injection mold life cycle.

- The Gate: gates wear out quickly. Therefore, keep that in mind while making a mold. Inserts that are both changeable and long-lasting must be incorporated into the gates’ construction. D-2 steel, CPM-10V, and carbide are the most popular choices for these inserts’ materials of construction. As such, the gate’s diameter must be big enough to let plastic that has melted into a liquid flow through and fill the hole. Where the gates are placed is also an essential factor to be considered during the injection mold design phase.

- Shrinkage: The materials’ shrinkage allowance must be considered when you design molding plastics to avoid faults in the final products.

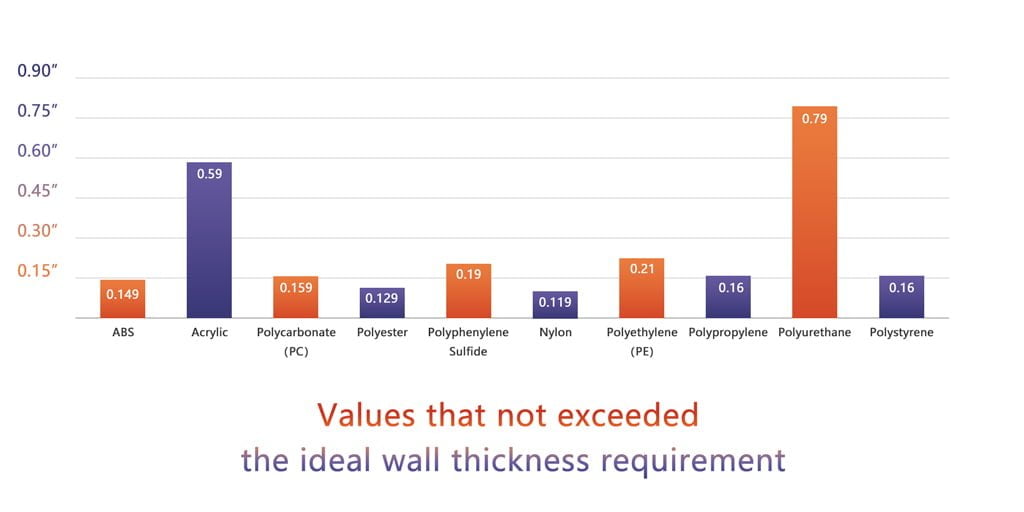

- Wall Thickness: The rate at which a mold cools is proportional to its wall thickness and the thinness of its walls. For the design molding plastic to cool at an even rate, designers need an exact calculation of the wall thickness. You can better understand the ideal wall thickness requirement that you should follow as per the table below:

- Draft: To remove the molded components, a draft must be built into the cavity and the core.

- Mold Filling: The gate position in a mold should be crafted so that the cavity is filled from thicker to thinner regions.

- Cooling System: If you want to shorten the cooling cycle time during the plastic injection mold design process, you must drill holes in both the cavity and the core.

- Polishing: When polishing the sprue, the runners, the hollow, or the core, it is essential to follow the direction of material flow.

These critical aspects can help make your plastic mold design process a success or a failure. So if you carefully consider these aspects, it can be easier to follow the entire plastic injection mold design manufacturing process, as discussed below.

How to Make A Plastic Mold Design for Injection Molding:

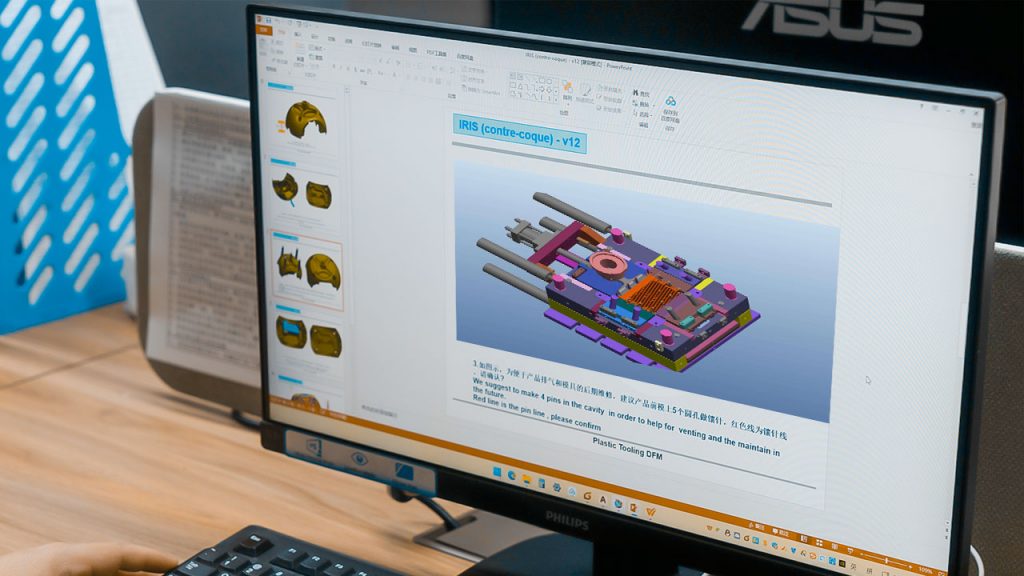

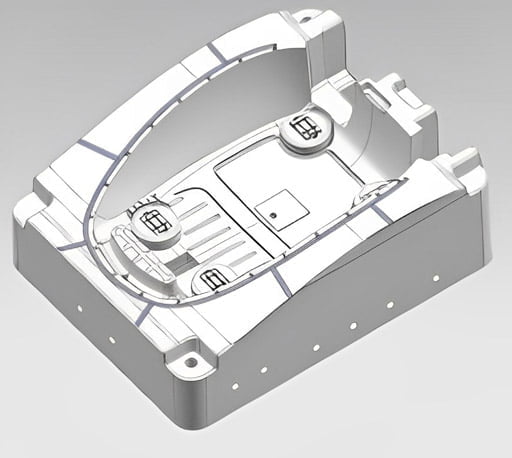

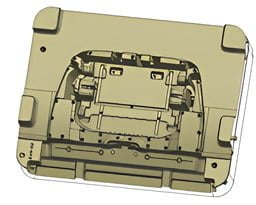

Step 1: Read the mold specification for injection mold design. These specifications typically include and can be seen:

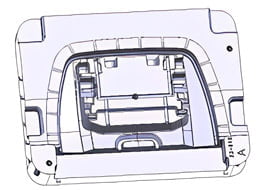

Step 2: Analyze the Product. For this, you need to consider the following:

- The structural analysis mainly includes structural analysis and the analysis of the tripping mechanism.

- Analysis of drawing Angle.

- Glue feeding analysis (Moldflow).

Step 3: Determine the Inner Mold Size. You can do this by considering the following:

- Several factors affect the safety value, like product size, cavity thickness, height, etc.

- Determining the height of the internal mold during plastic injection mold design

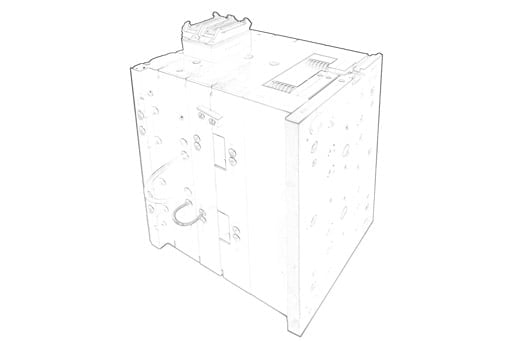

Step 4: Determine Mold Size. In this process, after finalizing the type of resin you want to use in the mold, you can ideally determine the appropriate size requirements as per the following method:

- In principle, the size of the internal die should not exceed the edge of the thimble plate. It is better to make the internal die 5-10 cm smaller than the edge of the thimble plate during plastic mold design.

- The distance between the center of the return pin and the edge of the inner mold should be 5-10 cm larger than the diameter of the return pin.

- The thickness of plate ‘A’ can have enough space for lucky water, and the thickness of plate ‘B’ should also be considered under the injection pressure to resist deformation, which generally does not need to be calculated but is determined by experience.

Structure Plastic Mold Design and Mold Marking Process to Design Molding Plastic:

In this process, the following things should be considered:

I. Processing Technology of the Factory:

- CNC (also known as computer gong, processing center)

- Electric discharge Machining (EDM)

- Wire cutting (EDW)

- Traditional processing technology: turning, milling, drilling, planning, grinding.

II. Once all the above-mentioned machining needs are fulfilled, you must proceed with the inner mold inserts to start the assembly process. This process can be ideally dealt with:

- Convenient Processing

- Convenient Material Selection

Choosing the suitable material for the molded product before proceeding with the injection molding mold design manufacturing process is crucial. Using the list below, you can pick an ideal material as per its abbreviation and raw material. Of course, you should also consider the parameters of these different materials.

| Raw Material | Abbreviation |

| Acrylonitrile Butadiene Styrene | ABS |

| Acrylonitrile Butadiene Styrene / Polycarbonate | ABS/PC |

| Engineered Thermoplastic Polyurethane | ETPU |

| High-Density Polyethylene | HDPE |

| Liquid Crystal Polymer | LCP |

| Low-Density Polyethylene | LDPE |

| Linear Low-Density Polyethylene | LLDPE |

| Nylon 6 | PA6 |

| Nylon 66 | PA66 |

| Nylon 12 | PA12 |

| Polybutylene Terephthalate | PBT |

| Polycarbonate | PC |

| Polyetheretherketone | PEEK |

| Polyetheretherketone | PEI |

| Polyethylene Terephthalate | PET |

| Copolyester | PETG |

| Acrylic | PMMA |

| Polylactide | PLA |

| Polypropylene | PP |

| Polyphenylene Ether / High Impact Polystyrene | PPE/PS |

| Polyphenylene Sulfide | PPS |

| Polystyrene | PS |

| Polysulfone | PSU |

| Polyvinyl Chloride | PVC |

| Styrene Butadiene | SB |

| Thermoplastic Elastomer | TPE |

| Thermoplastic Polyurethane Elastomer | TPU |

| Thermoplastic Vulcanizate | TPV |

Exhaust System

III. Surface Treatment Process. This process should involve the following:

- Surface drying lines

- Mirror surface treatment (mold saving and polishing)

IV. Air Avoidance and Rounding Related to Assembly. This is the process of handling structural design and selecting the ideal metal to finalize the injection molding process. First, you should consider the metal selection factors should in this process:

- Mold life.

- Precision requirements and appearance requirements of products.

- The size and complexity of the product.

- Cost of mold making.

In the End:

Following this guide in every stage of plastic injection mold design manufacturing, you can ideally conduct effective and reliable results in the end. However, even when you’re fully aware of the process, aspects involved in producing designed molded plastics and using plastic mold design for injection molding can be very complex and tricky.

Therefore, to ensure that nothing goes wrong and you acquire the results of injection molded plastic you desire, it’s crucial to rely on a team of professionals familiar with the different tasks involved in this production.

All in all, having skilled design engineers, programming engineers, product engineers, mold technicians, die-saving polishers, spark machines, wire-cutting operators, and procurement staff are crucial. Each of these experts is needed for specific roles, ensuring that every phase of the injection molding mold design is handled accurately, safely, and efficiently.

Since professional injection molding companies have an entire team of professionals working together in this production process, you can rely on them for careful and professional performance and results.