Injection molding is a common industrial technique that facilitates the creation of complex and precisely crafted plastic components. Several parts work collectively to guarantee proper mold alignment and functioning. A guide pin is an essential part of these mechanisms.

We will explore the usage and importance of a guide pin in injection molding, highlighting their contribution to precision, efficiency, and overall quality.

Usage of Guide Pins:

A guide pin, also known as an alignment or locating pin, are cylindrical components that aid in the alignment and positioning of mold halves in injection molding machines.

They are typically installed on one mold half, commonly the moving half or “B-side,” and fit into corresponding guide bushings on the mold’s stationary half or “A-side.” The guide pin ensures accurate alignment during the mold closing and opening cycles.

Importance of Guide Pins in Injection Molding:

1. Precise Mold Alignment:

One of the primary functions of guide pins is to facilitate precise mold alignment. By providing accurate positioning and guiding the mold halves, guide pins ensure that the mold cavities align correctly, maintaining dimensional accuracy and part quality.

Proper mold alignment minimizes the risk of defects, such as flash or incomplete filling, resulting in consistent and high-quality molded parts.

2. Improved Part Consistency:

Guide pins contribute to consistent part production by ensuring that the mold halves are aligned consistently for each cycle. This consistent alignment helps maintain uniform wall thickness, part dimensions, and overall part quality.

By minimizing variations, guide pins enhance part consistency, reduce scrap rates, and meet customer specifications consistently.

3. Reduced Mold Wear:

Efficient guide pins minimize friction and wear between the mold halves during the opening and closing cycles.

By providing smooth and controlled movement, guide pins help distribute forces evenly, reducing stress and wear on the mold components. This increases mold longevity, reduced maintenance requirements, and cost savings.

4. Enhanced Operational Efficiency:

Guide pins play a crucial role in enhancing the operational efficiency of injection molding machines. Their accurate alignment allows for faster mold closing and opening cycles, reducing overall cycle times.

By reducing downtime and maximizing production output, guide pins contribute to increased efficiency and improved productivity.

5. Mitigation of Mold Damage:

Improper alignment in injection molding can damage mold, leading to costly repairs or replacements.

A guide pin secures the plastic injection molding process against such damage by ensuring precise mold alignment. By preventing misalignment or collisions between mold halves, guide pins help maintain the integrity of the mold, reducing the risk of downtime and associated expenses.

6. Ease of Mold Assembly and Disassembly:

Guide pins simplify the mold assembly and disassembly processes. Their precise alignment enables easy and accurate reconnection of the mold halves, ensuring proper positioning.

This ease of assembly and disassembly saves time and effort during mold maintenance, reducing the overall downtime and allowing for quicker mold changeovers.

Machining of a Guide Pin:

The machining process of guide pins comprises numerous processes to produce precise and dependable components necessary for correct mold alignment in injection molding.

It includes:

Material Selection:

The first thing that must be done in the machining process is to decide what material will be used for the guide pins. Hardened tool steels, such as D2 or M2, stainless steels, or other alloys with great strength and wear resistance, are common for guide pins.

Other options include titanium and zirconium. Several criteria, including the molding method, the operating circumstances, and the anticipated loads, determine the choice of material.

Also Read: Metal Injection Molding: Everything You Need To Learn

Stock Preparation:

After the chosen material, the stock will be prepared to be machined. The selected material is normally available, depending on the application, as either round bars or cylindrical stock. The stock is examined to identify any flaws or blemishes that might affect the quality of the end product.

Turning is the most important machining operation for guide pins because turning is how they are made. During this process stage, the stock material is installed in a lathe machine, and a cutting tool is used to form the guiding pin and remove surplus material.

The lathe machine rotates the stock, and the material is removed by a cutting tool simultaneously to obtain the desired diameter, length, and shape.

Dimensional Accuracy and Tolerances:

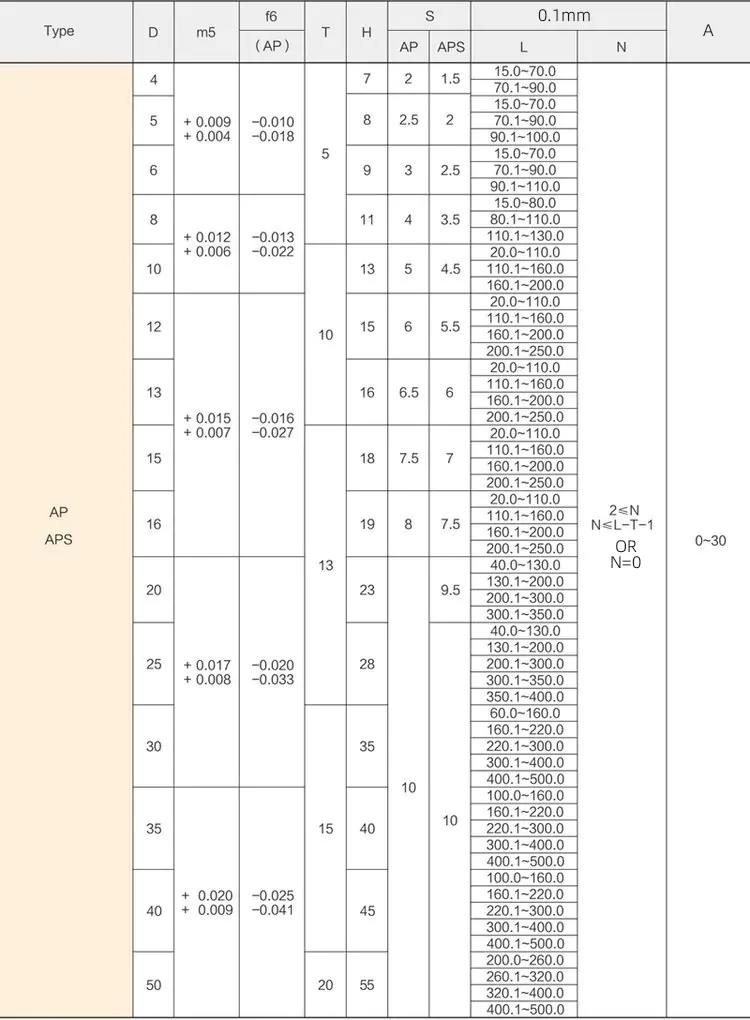

Both precise dimensional accuracy and tight tolerances are maintained throughout the turning process. To ensure that the mold components and guide bushings are properly aligned, the dimensions of the guide pins must be identical to those of the guide bushings.

Furthermore, technicians must pay careful attention to the diameter, length, and concentricity to ensure that the guide pins have an accurate fit and alignment within the injection mold.

Surface Finish:

Achieving a smooth surface finish on guide pins is essential since doing so decreases the amount of friction and wear during the mould operation.

To attain the necessary level of surface smoothness, we may subject the guide pins to additional machining processes, such as polishing or grinding, after the turning step has been completed. This step reduces the likelihood of the mold components being damaged while ensuring smooth movement.

Treatment with Heat:

Heat treatment procedures are common in the industry to improve the guide pins’ level of hardness and wear resistance. The processes of quenching and tempering are examples of common heat treatment methods.

These processes help strengthen the guide pins’ strength and longevity. The guide pins are subjected to heat treatment to withstand the strains and pressures exerted during the injection molding.

Inspection and Quality Control:

Following the machining and heat treatment operations, the guide pins are inspected comprehensively to guarantee high quality and adhere to the specified parameters.

To ensure that the guide pins meet the specified requirements, dimensional measurements, inspections of the surface polish, and hardness tests are carried out. Before the guide pins are allowed to be used, any deviations from the standard or deficiencies in the design are found and corrected.

Surface Coating (Optional):

In certain circumstances, the performance of guide pins can be further improved by putting them through surface coating processes.

It is possible to apply coatings such as titanium nitride (TiN) or diamond-like carbon (DLC) to improve the surface’s hardness, decrease friction, and increase resistance to wear. These coatings offer additional protection against wear, extending the guide pins’ useful lifespan.

Production Issues Caused Due To a Defective Guide Pin:

If a defective guide pin is used in injection molding, it can lead to several issues and negatively impact production. Here are some consequences that can occur:

1. Misalignment of Mold Halves:

A defective guide pin may not provide proper alignment between the mold halves. As a result, the mold halves may not be precisely aligned during the closing and opening cycles. This misalignment can lead to uneven plastic material distribution, causing defects such as flashes, short shots, or incomplete mould cavity filling. Misalignment can also result in excessive wear or damage to the mold and other guide components.

2. Increased Friction and Wear:

Defective guide pins may have surface imperfections, incorrect dimensions, or inadequate hardness. This can increase friction and wear between the guide pin and the bushing. The increased friction can lead to accelerated wear of the guide pin and guide bushing, causing dimensional inaccuracies, reduced lifespan, and potential damage to the mold and other components. Increased wear can also contribute to excessive play or binding, resulting in poor mold alignment and operational issues.

3. Binding or Sticking:

If a defective guide pin does not fit properly into the guide bushing or has surface irregularities, it can lead to binding or sticking of the mold halves during the opening and closing cycles. This can result in difficulties in mold operation, increased cycle times, and potential damage to the mold or guide components. Binding or sticking can also cause inconsistencies in part quality and lead to production delays or interruptions.

4. Inconsistent Part Quality:

Defects in a guide pin can also result in inconsistent part quality. Misalignment, excessive wear, or binding caused by defective guide pins can lead to variations in part dimensions, surface defects, or poor part aesthetics. Inconsistent part quality can impact product functionality and customer satisfaction and increase scrap rates.

5. Increased Maintenance and Downtime:

Defective guide pins may require more frequent maintenance and replacements. The increased wear and operational issues caused by defective guide pins can result in increased downtime for mold adjustments, repairs, or replacement of guide components. This can disrupt production schedules, increase costs, and decrease overall productivity.

6. Mold Damage:

Using a defective guide pin can lead to mold damage. Misalignment or binding issues caused by defective guide pins can result in collisions between mold halves, excessive forces on mold components, or other forms of damage. Mold damage requires costly repairs and can lead to extended downtime and loss of production.

Conclusion:

Guide pins are integral to injection molding and crucial in achieving precision, efficiency, and high-quality molded parts.

By enabling precise mold alignment, reducing wear, enhancing operational efficiency, and protecting the mold from damage, guide pins contribute significantly to the success of injection molding operations.

Manufacturers must understand the importance of utilizing well-designed and accurately manufactured guide pins to maximize their benefits and ensure optimal performance in the injection molding process.