Are you considering the usage of a CNC machine for your production demands? Whether you’re familiar with a CNC machine or opting for it for the first time, understanding the machine and its tools is essential to achieve efficient production outcomes. In addition, you can’t make or give production decisions to your processing manufacturer, like Prototool, without being familiar with what you need. Hence, a CNC machine comprises various tools. Each of these tools is used in different capabilities and production requirements. So, if you’re unaware of how they work and what outcomes they provide, making effective production/customization decisions can be challenging. This article will cover a detailed guide on a CNC fixture and its types so you can choose the ideal CNC fixtures before proceeding with CNC machining. Keep reading to learn more.

What is a CNC Fixture:

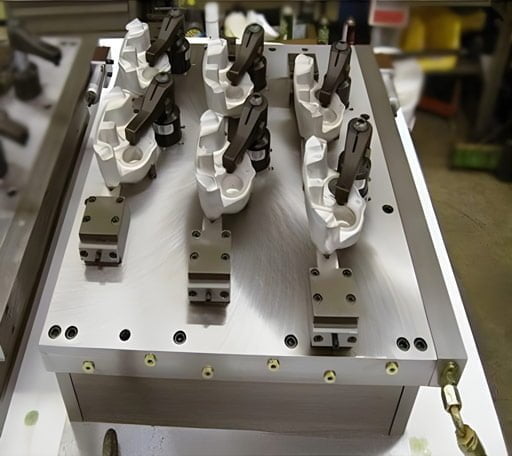

Before we proceed with the types of CNC fixtures and how you can pick the right one for CNC machining, it’s essential to know what CNC fixtures are in the first place. Precisely speaking, CNC fixtures are an agent of stability and placement. It is used as a tool in CNC machining, known as a work-holding device with several applications.

These applications of a CNC fixture are based on appropriately fastening, supporting, or mounting a workpiece or product on a CNC machine. As a vital tool for ensuring conformance and interchangeability, a CNC fixture is critical for managing and maintaining the production process in CNC machines. With CNC fixtures, the production process can be handled smoothly and efficiently per the production demands and product requirements.

CNC work-holding devices also lower the effort humans require throughout the manufacturing process. As a result, manual input and costs are also reduced with the presence of CNC fixtures in CNC machining. Due to this reason, many people relate CNC fixtures with jigs, which is another crucial tool in CNC machining. They are, however, not the same.

Where a jig guides the cutter’s movement, CNC work-holding fixtures, on the other hand, do not guide cutters. Instead, during the production process, they solely secure, support, and stabilize the workpiece, making the production process error-free, accurate, and efficient. Furthermore, with CNC work holding fixtures, the tool travels in tandem with the workpiece. In contrast, jigs in CNC machines keep the tool stationary.

Types of a CNC Fixture:

Moving forward, the performance and concept of a CNC fixture may seem simple, but it isn’t limited. Based on the power source, machining operations, and uses, there are different types of CNC fixtures used in CNC machining. Let’s explore each of them below in detail:

CNC Fixtures Based on Uses:

Among the wide range of CNC fixtures, a certain amount of these tools are used based on the different types of uses and outcomes they offer in the production process. Varying on the product type and how it should be manufactured, ranging from a simple surface finishing process to a metal surface finishing and much more, you can choose a CNC fixture per its applications. Below are five types of CNC fixtures that fall into this category:

- Special Fixtures:

A special fixture is a CNC fixture explicitly designed for a particular workpiece. They provide a significant benefit in terms of stability when utilized with a specific workpiece. These fixtures also provide faster functioning and more ease during use in CNC machining.

- Universal Fixtures:

Universal CNC fittings may be used on any workpiece and are easily adjustable. To accommodate any workpiece, each component of the fixture is adjustable and interchangeable. As a result, universal fittings, as the name implies, have an extensive scope and use. They can work with any workpiece and help manage and stabilize various surface finishing methods and other tasks/processes.

- Modular Fixtures:

A modular fixture can be quickly rebuilt and reconfigured to accommodate any workpiece. They are made of replaceable parts and are perfect for handling various work pieces. After the operation is completed, you can remove the fixture. Modular fixtures provide for a more efficient and adaptable production process.

- Combination Fixtures:

This type of CNC fixture comes in a variety of sizes and styles. Therefore, it is perfect for handling a variety of workpieces of various sizes and forms depending on the machine equipment.

- Assembled Fixtures:

After evaluating a workpiece, an assembled fixture can be put to use. The main reason behind this is the fittings of this type of CNC fixture. This fitting is designed to meet the needs of the workpiece. Hence, a unique approach is used for assembling these fixtures in the CNC machine. Moreover, depending on the situation, you can remove or reuse them.

CNC Fixtures Based on Power Source:

Some common types of CNC fixtures used in CNC machining, based on the power source of these fixtures that fit different types of the machine, include:

- Electric fixture

- Manual fixture

- Pneumatic fixture

- Magnetic fixture.

- Vacuum fixture

- Hydraulic fixture

CNC Fixtures Based on Machining Options:

Lastly, the wide range of CNC fixtures used in different types of machines today, as per their structure and tool installation design, include:

- Turning Fixtures

- Milling fixtures

- Boring fixtures

- Drilling fixtures

- Grinding fixtures

Based on CNC machining processes, you may draw a valuable conclusion about CNC fixtures. It is possible because every CNC machining procedure that necessitates the use of a fixture has a name. For example, a CNC machine based on surface finish or primarily focusing on machining surface finish may employ a CNC fixture to aid the surface finishing process. Likewise, a specific CNC fixture can be used for metal surface finishing CNC machines.

Choosing the Right CNC Fixture for CNC Machining:

Once you’re familiar with CNC fixtures and their various types, you can quickly explore which type of CNC fixture fits well with which application demands. Below are a few factors that you can consider as per the manufacturing demand to ensure that you pick the right CNC fixtures for CNC machining:

· Combination Clips/Building Blocks

Combination clamps, often known as “building block clamps,” are made up of several clamp elements with standardized designs, various functions, requirements, and sizes. “Building blocks” (different machine tool fixtures) can be readily constructed to meet processing needs.

Modular fixtures minimize design and manufacturing time, significantly reducing production preparation time, reducing the small batch production cycle, and enhancing production efficiency. Furthermore, the modular fixture offers excellent positioning precision, considerable flexibility, reusable energy and material savings, and cheap usage costs.

· Grips Hydraulic/Pneumatic:

Hydraulic/pneumatic clamps are specialized clamps that employ hydraulic or pneumatic components as power sources to position, support, and compress work pieces.

The fixture ensures the workpiece’s positioning precision, the machining accuracy is high, and the positioning and clamping operation is quick, saving time for workpiece clamping loosening. In addition, it has the benefits of compact construction, multi-station clamping, high-speed heavy cutting, automated control, and so on. Because of these benefits, hydraulic/pneumatic clamping is ideal for CNC machine tools, machining centers, and flexible production lines, particularly for high-volume processing.

· Electric Permanent Magnet Clip

The electromagnetic permanent magnet clamp is a new type of clamp built utilizing the most recent magnetic circuit concept and new permanent magnet materials such as neodymium iron boron as the magnetic source. The clamping and releasing procedure takes roughly 1 second, significantly reducing the clamping duration. With gripping forces exceeding 450Kgf, these clamps are appropriate for small and large-scale manufacturing.

The electric permanent magnet clamp may significantly reduce clamping time, multiple clamping times, and clamping efficiency. In addition, many machining methods have demonstrated that an electromagnetic permanent magnet CNC fixture may significantly increase the overall machining efficiency of CNC machine tools and machining centers.

It offers benefits such as quick clamping speed, ease of implementation of multi-station clamping, multi-face processing, stable and dependable clamping, energy savings, automated control, and so on. These benefits make this CNC fixture ideal not only for small-batch manufacturing but also for big-batch production.

· Fixture Base:

The smooth clamping seat may effectively minimize the manufacturing cycle of specific fixtures and manufacturing preparation time. As a result, it reduces the complete mass production cycle and enhances production efficiency. At the same time, the customized jig’s production cost may be decreased. As a result, the smooth clamping base is ideal for high-volume manufacturing with short cycle times.

Conclusion:

That’s all to our detailed guide on CNC fixtures and everything you need to know to pick the right CNC fixture for effectively handling machining tasks without any errors or defaults. In case of further queries, feel free to contact our professionals.