Manufacturing processes that use additive and subtractive processes have become more prevalent recently. The innovative creation of various parts is now advantageous to numerous businesses thanks to technological advancements. “Additive manufacturing vs Subtractive manufacturing” have different implementation strategies, yet they are interdependent because they are used most frequently. Nevertheless, other factors like production volume and the stage of product development influence the manufacturing technique utilized to make a prototype or part.

The comparison between additive and subtractive manufacturing is a common theme in this insightful article. In addition, we emphasize the key distinctions between Additive manufacturing vs Subtractive manufacturing procedures.

Additive manufacturing: What is it?

The process of producing 3D items via additive manufacturing, also referred to as 3D printing, is carried out in an industrial setting under computer control. Materials are deposited on a base material in layers. Adding materials together to produce a new thing is the main component of this technique. Additionally, the type of material used in additive manufacturing depends on the printing procedure. Alloys of metal, thermoset polymers, composite materials, and thermoplastics are also included in this group.

Moreover, only the aerospace and medical sectors first used AM technology, but this has since changed, and it is now used in a variety of sectors. Further evidence of its ever-expanding reach may be found in end sectors, including heavy machinery, oil, gas, and vehicles.

Processes for Additive Manufacturing:

The procedures used in additive manufacturing are often divided into groups, which include the following:

DED: Directed Energy Deposition:

The process of creating 3D things with this technique is difficult. Additionally, powder or metal wire are frequently used materials. A laser or concentrated beam causes the material to melt and is then precisely poured into the building platform. Until the last stage, the process of the liquid solidifying to form a layer continues.

Using Extruded Materials:

With the help of a glue gun, the technique is effective. Through a coil, the material is sprayed into the printer using this capability. The heat from the nozzle tip melts the material, which is then, layer by layer, applied to the build platform to solidify and create the item. Although it has significant restrictions, this type of additive manufacturing is the most expensive one.

Binder Jetting:

A binder is selectively deposited using this additive manufacturing process onto a powder bed to create solid layers. Additionally, granular materials such as metals, sand, and ceramics must be employed for this kind of 3D printing method.

Binder jetting also utilizes a roller to distribute a powdered substance on the construction platform properly. The powdered substance is then subjected to the method’s subsequent stage, which involves the selective deposition of binder glue. When the formation is complete, the roller spreads a second layer of powder over the first one using glue.

PBF: Powder Bed Fusion:

Different AM techniques, such as Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Selective Heat Sintering (SHS), Electron Beam Melting (EBM), and Direct Metal Laser Melting are all included in PBF (DMLM). In addition, this technology melts and fuses tiny layers of material in three dimensions using lasers, beams, or print heads. After that, it discharges extra product powder.

Lamination of a Sheet:

LOM (Laminated Object Manufacturing) and UAM (Ultrasonic Additive Manufacturing) are the two primary techniques for laminating sheets (UAM). While LOM uses original materials made of adhesive-coated paper sheets, which are the best for modeling objects with a pleasing appearance, UAM uses ultrasonic welding to combine thin metal sheets.

Photopolymerization of VAT:

In a vat of liquid resin photopolymer, photopolymerization creates an item. With the aid of ultraviolet sunlight, the photopolymerization process now cures the microfine resin layer. Then, using a mirror, these light rays are directed in the direction of the object.

Jetting of Materials

Similar to binder jetting, but using wax instead of resin as the binder. Instead of utilizing adhesive on the powder bed, the operation uses a comparable layering of materials to build an object. Wax is left on a construction platform by MJ. The majority of producers favor MJ since it is less expensive and provides superior precision and surface qualities.

Subtractive Manufacturing: What is it?

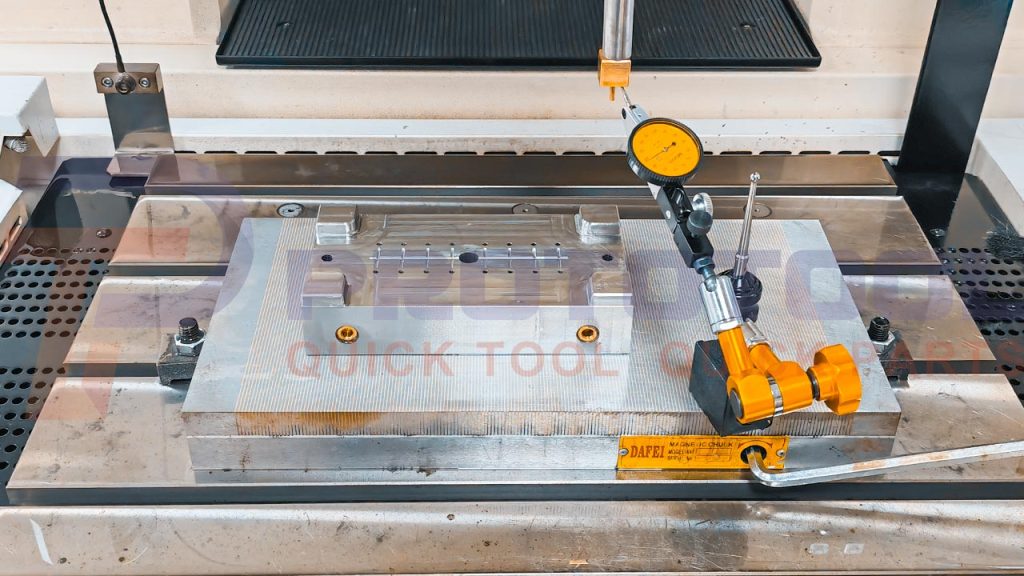

As the name suggests, subtractive manufacturing requires removing components from an object to produce a new one. Additionally, it might mean removing pieces of a solid piece of wood, plastic, or metal. An effective illustration is a milling machine that hollows out plastic or metal. This manufacturing method also enables the designing, prototyping, and manufacturing of materials intended for final use.

It is the ideal way to obtain particular mechanical qualities or finishes for production in both small and large volumes. Wood, aluminum, brass, ABS, POM, nylon, PEEK, PVC, plexiglass, PCA, and Polypropylene are a few examples of the metals or resins it can use. Furthermore, subtractive manufacturing methods make it simpler to match the material’s strength, flexibility, chemical resistance, or other dielectric qualities to the design.

Processes Used in Subtractive Manufacturing Include:

Cutting, machining, and abrading are a few examples of subtractive manufacturing processes that are frequently used. Here are some specifics for each.

CNC Machining:

A method of production known as CNC machining uses pre-programmed computer software to control industrial tools and machinery. With just one set of instructions, this form of subtractive manufacturing can finish three-dimensional cutting tasks. Before a CNC system is activated, however, it is necessary to program the required cuts into the software, which instructs the relevant machinery and equipment on how to carry out the defined dimensional duties.

Although faults are more likely when a CNC machine is cutting in more than one direction at once, the code generator within the numerical system typically assumes that mechanisms are error-free when CNC programming.

Cuts With a Laser:

A laser is used in this procedure to shape-cut various materials. The industrial and creative industries frequently employ the materials produced by this method. Optics and Computer Numerical Control (CNC) assist in focusing the strong laser beam on the material during the laser cutting process. To ensure that the CNC cuts the material in the appropriate pattern, a motion control system is used. The final step assures a high-quality surface finish through vaporization or high-pressure jet gas.

Abrading:

By grinding or brushing away pieces of a material, an abrasive is used in the abrading process. Materials are ground, sanded, or polished by abrasives, which are abrasive substances. Additionally, they can smoothen their surface or remove material bits by vigorously rubbing them. Abrasives can also be incorporated into a suspension in a liquid or applied to a hard surface. They should be tougher than the substance being removed to be more efficient.

Electric Discharge Machining (EDM):

Electrical discharges are used in EDM, a subtractive manufacturing technique, to produce the required shape. Also known as wire erosion, die sinking, spark machining, or spark eroding.

It also functions by utilizing a series of swiftly repeated current discharges between two electrodes (the electrodes on the tool and the electrode on the workpiece), separated by a dielectric liquid and exposed to an electric voltage. The removal of materials from the workpiece is the EDM process’s apex. Additionally, during this procedure, there is no physical touch between the tool and the workpiece.

Which manufacturing method—additive or subtractive—is better?

Even though the additive manufacturing and subtractive manufacturing processes are completely distinct from one another, they more or less complement one another.

To begin with, you must employ both procedures while creating prototypes and concept models. This is understandable since, on the one hand, additive manufacturing aids in the manufacture of small components and their intricacies, and, on the other hand, you may make adjustments as necessary because the process is still in its early stages. Since larger items can have more surface finishes, subtractive manufacturing is also more suited for them.

In the end, both additive manufacturing and subtractive manufacturing works well together. Together, you may make a huge variety of products, depending on the need and what is required.

How do you pick the best one?

Between Additive manufacturing and Subtractive manufacturing, your proposed application will determine which is best. Both subtractive and additive applications include the following:

Application of Subtractive Manufacturing:

Large batch production is perfect for this manufacturing technique, which has the following applications:

- Fabrication of textured surfaces and contoured profiles

- Innovative features for the home, vehicle, electronics, aerospace, dental, and medical industries.

Application of Additive Manufacturing:

There are many uses for additive manufacturing as more businesses adopt these techniques and come up with inventive ways to combine them with subtractive manufacturing, including:

- Manufacturing of Jewelry

- The aerospace industry

- Enhancement of Energy Use

- Manufacturing of models for industry

- Electromechanical and robotic systems

- Solid Freeform Characteristics

- Electromagnetics, metamaterials, and three-dimensional electronics

- Dental and medical aspects

Conclusion:

Whatever strategy you take in “Additive manufacturing vs. Subtractive manufacturing,” you must completely develop your concept before spending money on manufacturing. From design to prototypes, Prototool is a reputable company that implements these manufacturing procedures. Additionally, while upholding the necessary standards, they may make the greatest quality parts to satisfy the needs of their clients.