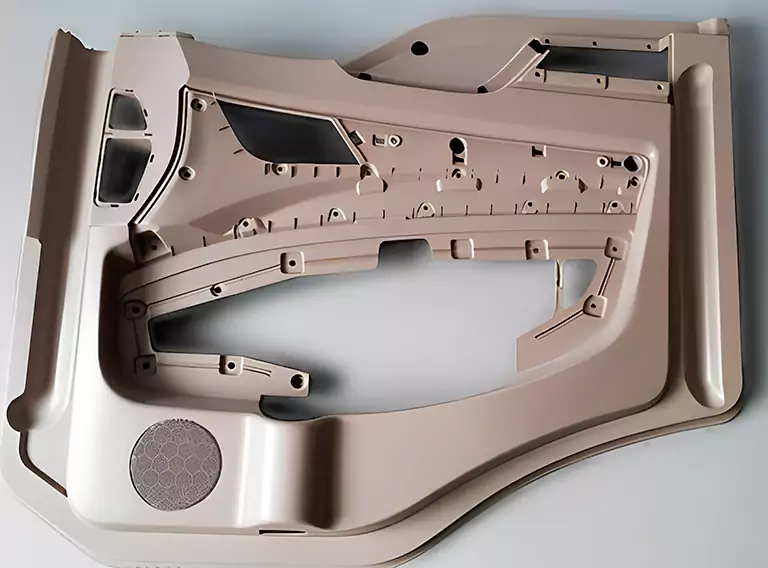

Today, plastic injection molding has become a widely used production technology in the automotive industry for manufacturing complex, high-precision, and durable components that meet strict safety, reliability, and quality standards. The process of producing plastic injection molding parts for automotive products involves injecting molten plastic into a mold cavity, where it solidifies and takes on the shape of the mold. This technology has been utilized to manufacture various automotive parts, including dashboards, door panels, bumpers, and engine components.

In this article, we will explore the production technology of plastic injection molding parts for automotive products, the advantages of this technology, and the various factors that influence the quality of the final product. Understanding the plastic injection molding process for automotive parts can help manufacturers produce high-quality parts that meet the rigorous standards of the automotive industry.

Plastic Injection Molding Parts for Automotive Products: A Brief History

In the past, cars were almost exclusively built of metal in the early days of the automobile industry, which meant they were ungainly and incredibly heavy. However, as technology improved, the plastics business exploded in the 1940s and 1950s. As a result, automakers began experimenting with plastic car parts.

The first cars with plastic ornamental components were introduced in the 1970s. Later in the 1980s, they added more functional components such as plastic headlights, bumpers, and fenders.

Automotive manufacturers debuted the first plastic structural components for automobiles in the early 2000s, which had the advantage of being lighter than their metal equivalents, allowing for increased fuel efficiency and lower production costs. In today’s automotive sector, injection molding is the primary production process for producing plastic automobile parts.

Injection Molding Materials Used for Automotive Parts:

Nylon and PA

Nylons offer strong abrasion and chemical resistance despite not being liquid-resistant. They can be formed into automotive parts such as bushes and bearings.

ABS

ABS is a weather-resistant material widely used for injection molding and 3D printing. It is used in automobiles to construct dashboards and coverings.

Polypropylene (PP) (PP)

Automobile part makers use PP for more high-intensity vehicle parts, such as various external components. This is because it is resistant to water, chemicals, and ultraviolet radiation. Bumpers, cable insulation, and battery covers are examples of PP components.

Acrylic‘s transparency (and shatterproof) properties make it an excellent (and shatterproof) alternative to glass. A plastic automobile parts maker may use molded PMMA for headlight covers and internal screens (e.g., SatNav or radio).

Polyurethane (PU) (PU)

PU is frequently found in spongy and flexible materials such as foam chairs. This includes automotive seats, but PU is also used in seals and gaskets, insulating panels, and suspension bushings.

Composites with Reinforcements

Glass or carbon fiber-reinforced plastics, which are substantially stronger than standard resins used in the fabrication of automotive bodywork and bumpers, can be used by manufacturers.

Polyvinyl chloride (PVC) PVC is the world’s third most prevalent synthetic plastic polymer, and it is utilized in many molded parts that require strong chemical resistance in the automotive sector. Interior panels, dashboards, and cable insulation are examples of these.

Production Phases Involved in Automotive Parts Production:

Injection Molding Machinery

Because auto parts differ significantly from conventional mobile phone cases, household appliances, and other plastic products, a significant portion of the product is larger, the cavity surface is very complex, the structural position in the plastic process is not equal to the force, the stress distribution is naturally difficult to balance, and the key consideration in the design is its required processing capacity.

In general, clamping force and molding capacity represent an injection molding machine’s processing capability (expressed in terms of maximum theoretical injection volume). When the injection molding machine molds the product, the clamping force must be greater than the mold opening force created by the mold cavity pressure, or the mold parting surface will overflow.

Injection Molding Procedure

It has become well-known in the injection molding business since the advent of scientific injection molding. It is doubtful whether scientific injection molding can bring much revolutionary technological change to the mechanics of the production site. Still, its impact on improving refined products on the production site is not insignificant. Anyone who uses scientific injection molding will deeply understand this.

In comparison to complicated technical lectures, the “scientific injection molding procedure” can be broken down into six links:

- Freeze test with glue in the mouth

- Flow balance analysis

- The viscosity test

- The flow of water test

- Test for the best cooldown time

- Run an empty mold test

Of course, many international businesses have begun to adjust goods through mold cavity-embedded induction equipment for cavity analysis technology, as summarized in the preceding six parts.

Furthermore, we make a short technical statement for thick-walled goods in car components today, and we examine thick-walled products using light guide production.

Quality Assurance

It is tough to understand a quality job if you are not a professional quality management personnel. The level of cooperation is neither mindless compliance nor stagnation while waiting for a decision. “The first three terrible management” is the most direct technique to collaborate with production.

The bad ratio in the production process of each product is sorted out on the shift with regular or irregular inspections as the supervision means of the daily production report, and the technical team inside the workshop counts and reviews the first three defects of the product, and continuously improves the bad phenomenon, and this improvement never stops.

There are various contradictions with production in many factories, regardless of what kind of high-level attention is given to quality. The reason is that any cooperation matters beyond the scope of the department’s work, and if the senior leaders always stay out of the matter and treat it in a way that only the result cares about the process, it is certain that the quality will come to a complete halt.

Typical Mold Adjustment for Molding of Specific Automotive Parts

In this process, you need to know that many adjustment processes are based on personal experience or inherent parameters but are frequently at a loss after abnormal problems, so the initial preparation materials on the temperature setting must have the raw material physical property table provided by the supplier, and formulate the correct material temperature and mold temperature based on this data. Generally, the initial adjustment must be performed in two ways: the upper and lower limit debugging of the raw material temperature, with the lower temperature being preferable regarding product quality.

More Things To Consider About Plastic Injection Molding Parts

1. Speed is generated by pressure; if the injection pressure is as high as 90% and the speed is only 10%, we have not witnessed the oil pressure gauge, which indicates the true pressure. Similarly, if the speed is 90% and the pressure is just 30%, are you confident that the speed will reach 90%? As a result, technicians must be monitored before multi-stage injection molding to ensure that no adhesive samples are missing. Only in the absence of irregularities can the parameters created be more reasonable and better achieve interchangeable production.

2. Pressure holding is only based on naked eye observation of the product without defects, which is, of course, incorrect; the main influencing factor of the product’s plastic sealing time is the holding pressure and the holding time, in general, when the pressure holding can be enough to make the product shape when saving data, from this stage to continue to accumulate the pressure holding time in 1 second, until the single weight of the product is completely set.

3. And lastly, glue melting and back pressure these two points directly affect the state of the melt in the mold cavity. When the back pressure is insufficient, the measured value will greatly exceed the required measurement, resulting in various defects such as silver wires, bubbles, shrinkage, and other imperfections in the product due to the unfavorable condition of the melt.

Advantages of Using Complex Automotive Parts in the Automotive Industry

Plastics may be processed and molded simultaneously, with a short processing time and guaranteed precision; Experiments can be conducted with the customer’s consent to recycle for over-molding, and the rate of recycling waste products is also very high.

The plastic product itself is lighter, and at the same time, it has good elastic deformation; it can absorb a large amount of collision energy, and the cushioning effect on strong impact is better than it would be with other materials. This will play a better protective role for the vehicle and the occupants of the vehicle.

Numerous automobiles have bumpers made of plastic at both the front and the back to absorb some of the force of collisions with objects outside the vehicle. Plastic also has the function of absorbing vibration and noise and reducing their intensity, which can contribute to an increase in riding comfort. As a result of having received bumper orders from Ford, GAC, and even Land Rover for an extended time, several mold companies are now at an advanced stage in production technology.

Plastic has high corrosion resistance, and even localized damage won’t cause it to deteriorate. In car air conditioning and refrigeration systems, it is practically impossible to come across components that are not made of plastic.

By adding various fillers, plasticizers, hardeners, and elastomers, you can build modifiers to adapt to the use and requirements of various vehicle parts. For several years, each of the 18 divisions that make up the BYD Group has been able to modify its raw materials to meet the requirements of its products. It is more convenient that the plastic color can be modified by the masterbatch and toner, reducing the difficulty of painting. Plastic also has a better electroplating performance than other materials.

—–

For more details and queries, feel free to contact us at Prototool.