Electrode machining is among the newer metal processing techniques, compared to rotating cutters, shearing, and forging. This machining process passes rapidly pulsed high-voltage electrical discharges (sparks) across the gap between the electrode and the grounded workpiece.

As a result, it helps remove the material from the workpiece by erosion. This way, even the most complex and intractable material can be cut and machined with very little bulk heating and virtually no application of macro forces, provided that the material is electrically conductive. This results in very low distortion and no addition of meaningful residual stresses to the workpiece.

But wait! Why should you opt for electrode machining for your production needs? Let’s go ahead and explore all that and much more about it.

What is Electrode Machining?

Electrode machining, also known as electrode manufacturing, is used to create or shape electrodes for various applications, particularly in EDM.

Simply put, electrode machining is a versatile process that can manufacture intricate contours and shapes in various materials. The procedure calls for applying electric discharges to carve out the desired form and remove unwanted material.

How Does the Electrode Machining Process Work?

Electrode machining involves several steps to create or shape electrodes for use in Electrical Discharge Machining. Here is a detailed explanation of how it typically works:

● Design and Preparation:

The first step is the design and preparation phase. The electrode’s design is created using computer-aided (CAD) software, specifying the desired shape, dimensions, and features. Once the design is finalized, the appropriate electrode material is selected based on workpiece material, machining parameters, and desired surface finish.

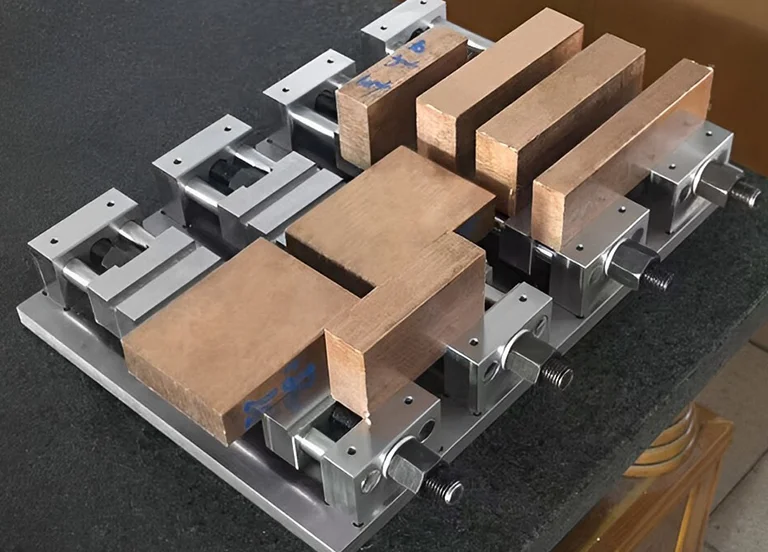

● Electrode Material Selection:

The choice of electrode material depends on various factors. Commonly used materials include copper, graphite, and tungsten copper alloys, which offer good electrical conductivity and heat resistance. The selected material is prepared, cut to the desired size and shape, and ready for electrode machining.

● Machining Techniques:

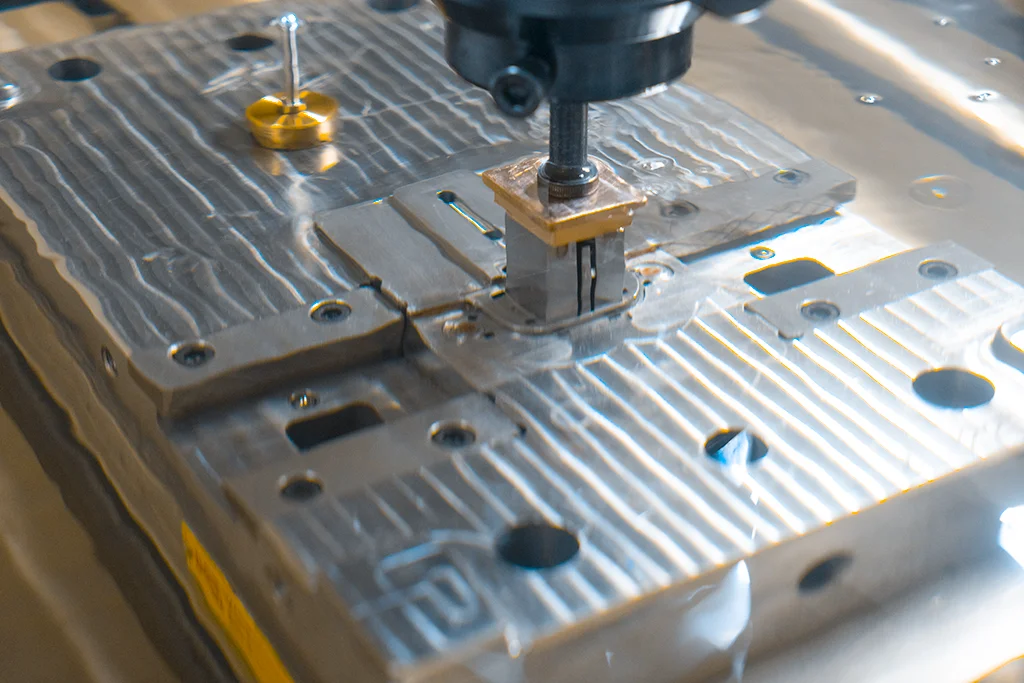

Electrode machining involves various techniques to shape the electrode material into the desired form. The specific technique depends on factors such as the complexity of the electrode design, the material being used, and the precision required.

Common machining techniques include milling, turning, grinding, or electrical discharge grinding. These techniques remove excess material and create the electrode’s desired shape and features.

Also Read: CNC machining aerospace parts: the Most Popular Processing In Production

● Surface Finishing:

After the initial machining process, the electrode may undergo surface finishing to achieve the desired surface quality and dimensional accuracy.

Finishing techniques such as polishing or grinding may remove any roughness, burrs, or imperfections on the electrode’s surface. This helps ensure the electrode meets the required specifications and provides optimal performance.

● Inspection and Verification:

Once the electrode is machined and finished, it undergoes inspection and verification to ensure it meets the required specifications. This involves dimensional measurements, visual inspections, and functional tests to confirm accuracy, surface finish, and suitability for the intended electrode machining process.

Moreover, the electrode’s dimensions and features are checked against the CAD design to ensure it matches the intended requirements.

● EDM Process:

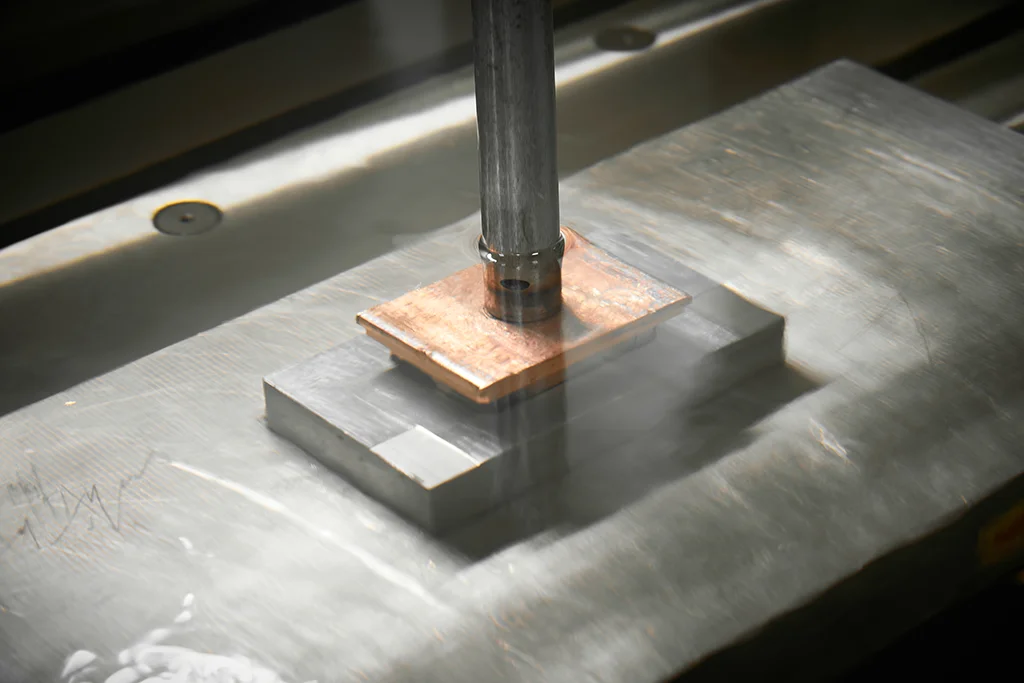

The machined and verified electrode is then used in the EDM machine. In the EDM process, the electrode, connected to the machine’s power supply, is positioned close to the workpiece.

Rapid electrical discharges occur as the electrical current passes between the electrode and the workpiece, creating sparks or plasma that erode the workpiece material. The electrode’s shape and dimensions determine the shape and features produced on the workpiece.

● Maintenance and Optimization:

It’s important to remember that electrodes may wear out or degrade over time due to the electrode machining process. Therefore, regular maintenance, such as electrode cleaning, reconditioning, or replacement, is necessary to ensure optimal performance and accuracy.

Optimization techniques, such as electrode wear compensation and toolpath adjustment, may also enhance the electrode’s longevity and machining efficiency.

Electrode Machining on Different Materials: The Comparison

The following is an in-depth comparison of the machining done by electrodes on various materials:

| Material: | Usage Frequency | Properties | Design Solutions/Machining Process | Preferred Industry |

| Steel: | It is utilized extensively in the steel machining industry. | Because of its high conductivity, steel is an excellent choice for the electrode machining processes. | Steel, even steel that has been hardened, can be formed into intricate shapes and features thanks to a process that allows for this. | Because it is possible to achieve a high level of precision and surface finish with electrode machining, this technology is ideally suited for producing tools and dies, molds, and precision components for the automotive and aerospace industries. |

| Aluminum: | It is also used for machining aluminum products, even though working with aluminum presents a different set of challenges than working with steel. | Aluminum is a highly conductive material, which makes it possible to be carried out effectively. Aluminum’s lower melting point makes it prone to thermal damage during the process. | To prevent excessive melting and achieve the desired results, we need to exercise proper control over the process parameters, such as current, pulse duration, and electrode material. | It is frequently used in aerospace to create aluminum components with intricate shapes and cooling holes. |

| Copper: | This technique can also be used to machine copper, which can be machined using this process. | Much like aluminum, copper has a low melting point, making it susceptible to damage when subjected to high temperatures. | During the machining process, extra precautions must be taken to avoid melting the material to an excessive degree and to keep the dimensions accurate. | The electrical and electronics industries frequently use electrode machining to produce copper electrodes, electrical contacts, and precision components. |

| Titanium: | Titanium, unlike other materials, is more preferably machined using electrode machining. It is mainly because this method relies on something other than mechanical force or cutting tools to complete the process. | Titanium’s high strength, low thermal conductivity, and high melting point make it a complex material to machine. This material also has a high melting point. | Titanium can be efficiently stripped of material using electrode machining, even in a hardened state. This can be done without sacrificing dimensional accuracy or surface finish. | The aerospace and medical industries extensively use the process to produce titanium components, such as turbine blades, implants, and surgical instruments. |

| Ceramics: | Ceramics, which are notoriously difficult to machine using traditional methods, are one of the materials that can be machined, which is another application of this technique. | Because ceramics are electrically insulating materials, specialized EDM processes called “Electrical Discharge Grinding” (EDG) or “Electrical Discharge Diamond Grinding” (EDDG) are required to grind ceramics. | In these processes, conductive graphite or metal tools are used as electrodes to make the material removal accomplished through electric discharges easier. | Ceramics such as alumina, silicon carbide, and zirconia can be machined using electrode machining, which allows for the production of intricate shapes and features for use in applications within the electronics, biomedical, and semiconductor industries. |

Conclusion:

To summarize, electrode machining is a versatile process used on various materials, such as ceramics, steel, aluminum, copper, and titanium. Even though every material has challenges, this technique can provide precise contouring and generate intricate features for various industrial applications.

However, even with advanced machining solutions, technicians need to make sure that electrode machining is conducted carefully. Specifically, it’s crucial to pay attention to the parameters of the process and the materials used for the electrodes to achieve the best possible results and prevent unfavorable thermal effects.

FAQ:

Which Type of Electrode Machining Technology Is Ideal for Creating Parts with Complex Cavities?

Typically, sinker discharge machining is the best type of electrode machining technology for making products with cavities that are hard to reach. It lets designers make more complicated holes, often needed for plastic and die-cast parts.

However, sinker discharge isn’t much less helpful in molding because it can’t make every hole shape. The “line of the draw” that stops EDM from making undercuts also applies to plastic molded and die-cast parts, which go into the tool hole as a liquid but come out as a solid.

What is the Purpose of Using Electrode Machining?

Electrode machining is an alternative to traditional hard-material machining processes, particularly refractory metals and difficult-to-cut forms. In terms of diameter and roundness, wire electrode machining and hole-drilling electrode machining can attain otherwise unthinkable tolerances in precision cutting.

Moreover, it can maintain excellent precision and very low Ra values (high-quality surface finish). This trait leads to less post-processing, sometimes lowering costs for components that would otherwise be extremely difficult to manufacture.

Suggested: CNC Machining Tolerances: Everything You Need to Know In 2022

—-

Still, have questions? Ask our professional team of machining technicians at Prototool.com.