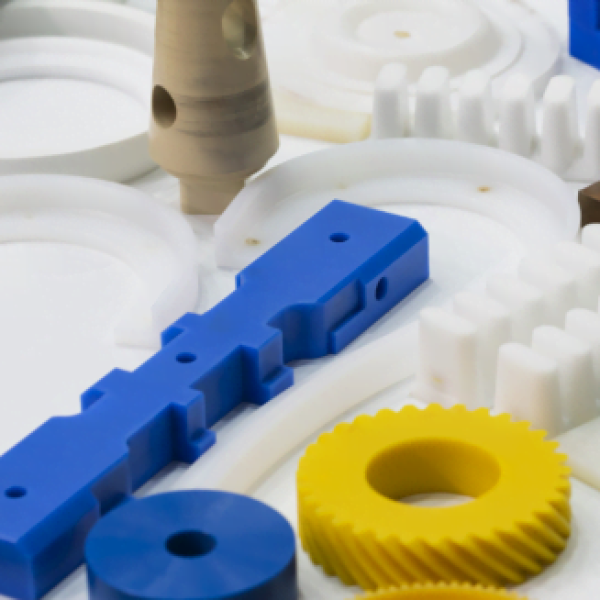

Vacuum Casting services

- Tight tolerance ± 0.01 mm

- Mass production capability

- delivery as fast as 1 day

Vacuum Casting service allows Prototool to make machine parts on demand. Vacuum Casting is a low-volume process for businesses looking for high-quality and consistent machine parts, fast at the lowest price by utilizing quick curing silicone molds and 3D printed master patterns. It is a process of three-dimensional printing a specific design to create a mold of silicone gel. The mold casts identical parts using Vacuum . Parts manufactured with this process require tooling, a master pattern, and Vacuum part material to create multiple copies of a part in a shortened timeframe, bridging the gap needed for high volume production.

Why Choose Us

Prototool is fully adept at handling your vacuum casting and silicone molding needs. With years of expertise in this field, we can mold your plastic parts to the most exemplary standard, cost-efficient, and fast turnarounds. It is an excellent method for making rigid or flexible parts and is ideal for high-quality prototypes. Vacuum casting parts can be made from a few to hundreds as required. You can choose our services since we provide:

The economy of scale

It is much cheaper in any volume, and an excellent low-budget alternative to other techniques since no expensive metal tooling is needed when dealing in small quantities.

Repeatability

If several copies of the part are required, vacuum casting is what you need.

Excellent surface finish

We produce generally less robust parts and has an excellent surface finish with durable parts and production-level quality and provides end-user, rigid, flexible, and rubber parts.

Fast lead time

We offer a wide range of solutions to help you develop an effective “master pattern” and scale up to production parts by letting our team commit to you to create and iterate at a much higher speed, which can be as fast as 1 day.

How To Work With Us

Here is the typical working order to expect when you hire us for our vacuum casting services:

Submit Request

Submit request with a description and technical drawing of your product. In case of no technical drawing, no worries. We can reverse engineer.

DFM & Quotation

We usually get back to you within 24 hours.

Manufacturing

Once you approve the quote and make the deposit, we start working on the initial work of tooling, creating the mold etc.

Shipping

Packaged, labeled, and shipped to your door right on time

Get in touch with us virtually from anywhere in the world!

Free quoting, Quick reply within 24hrs.

What We Can Do

Master Pattern Made

Manufacture a master patterm according to your design file. Or you can just send us one product as master pattern.

Silicone Molding Making

Making silicone mold using the master pattern.

Parts Production

Get your parts for end-user testing or short-run production.

Material We Used

There are so many different types of materials, depending on what properties you’re looking for. We consider the material properties, manufacturability characteristics, cosmetic appearance, and total cost when selecting a material. Advanced Formula Polymers have outdone themselves in vacuum casting. Additionally, Shore D vacuum is rigid, while shore A vacuum is elastomeric. Platinum-based silicone-based compression cast materials have also been in use. Vacuum cast materials divide according to their properties, surface finish, and applications, such as Rigid Polyurethane (Black, Natural, Color-Match), Rigid Clear Polyurethane (Colorless), Rubber-Like Polyurethane (Black, Natural, Color-Match), and Clear Rubber-Like Polyurethane (Colorless).

tolerance

The vacuum casting process’s tolerance range is +/-0.01 mm, and the tolerance range for each process type may be different. Likewise, injection molding tolerances are +/.005″ for the first inch and +/-.002″ for each inch after that. The tolerance value shows a standard deviation in vacuum casting parts. Tolerance ranges are available concerning the size of the designed machine part, surface finish, internal and external grow lines and quality, shrinkage rate due to thermal expansion, and distance dimensions. Metal inserts maintain tight tolerances in bores and crucial regions.

Finishing

Vacuum-Casted parts can be either rigid or flexible, even rubber-like, depending on the type of Urethane used. We offer Urethane in various color options: transparent (standard), black, and color matching. Parts may also have a standard, smooth, or custom finish, including adding hardware installations and painting. If surface finishes such as SPI and VDI surface textures are required, CNC machining the master pattern and finishing it is preferable. By spraying or painting the master pattern, we can produce surface textures like gloss and matt. The surface finish depends on the component post-processing. It is sometimes confined to the outside because some interior aspects of the design are impossible to reach.V

Industry application

The vacuum casting process is ideal for situations where a few parts are of high quality, precise, and have the performance characteristics required in production parts. Using premium grade urethane in custom formulations, we produce the highest quality of customized cast urethane parts and can also create prototypes from your drawings or sketches. The vacuum casting process and relatively inexpensive tooling make it easy and economical to make any design changes. The vacuum casting process can produce medical devices, housing and enclosures, sporting equipment, low-volume production parts, cases and covers, and prototypes. Some industrial applications of vacuum casting are:

- Engineering models

- Marketing test samples

- Pre-production runs

- Test prototypes

- Rapid prototypes

- Bridge to production

- Production of display parts

- User evaluation

- Consumer testing

- Low-volume manufacturing

- Concept models

- Sales samples

Vacuum Casting Services FAQs

Vacuum Castings for Full-Scale Production? Can You Do It?

Vacuum casting is normally for prototypes and small batches, but with enough lead time we can do larger production runs depending on the project requirements and whether or not it’s possible to use this process all the way through in your particular case.

What's the Maximum Size Limit for Vacuum Casting Parts?

The actual limit depends on our ability to cast. We are able to accommodate different sizes and will work with you to decide if this process is suitable for your parts dimensions.

Compared to injection molded parts, how durable are vacuum casted ones?

Vacuum casted parts tend to be very robust, and often can recreate the characteristics of injection-molded parts. But it is ultimately the material used that determines whether a given part will have strength and durability.

Can vacuum casting recreate textures and fine details?

Yes, vacuum casting is very good at reproducing textures and fine detail; the accuracy of this method can be as high as 0.1 mm, with an excellent surface finish so that it is suited to complex designs

What Types of Materials are Suitable for Vacuum Casting?

We supply products in different grades of polyurethanes, enabling vacuum castings to resemble plastics and rubbers as well as some metals.

Small Production Runs: Cost-Effective?

Vacuum casting is very competitive cost-wise for low volume runs. It does not require the expensive tooling of injection molding and can produce parts quickly, easily and inexpensively.

How Quickly Can I Have Parts from Vacuum Casting Services?

The turnaround time for vacuum casting services is usually quite short, often within days or less. It depends mainly on how difficult the part and its quantity are to cast.

Can Vacuum Casting Make Functional Prototypes?

Oh, yes indeed. Vacuum casting is perfect for producing a functional prototype that can test and verify before moving to mass production.

Finishing Options for Vacuum Cast Parts?

As for vacuum cast parts, we have varied choices in terms of finishing including painting, texturing and polishing to achieve the desired aesthetic as well as performance characteristics.

But how do we ensure quality and uniformity in vacuum casting?

Rigid control of processes, combined with high quality materials and strict inspection on every part produced ensure that the vacuum casting will meet our stringent standards.

How accurate are vacuum cast parts?

The vacuum cast parts have become the calling card of accuracy. They are made to extremely tight tolerances, and suit very precise work well.

How does vacuum casting stack up with respect to finish and detail when compared to 3D printing?

With vacuum casting, the surface finish and details are generally smoother than regular 3D printing.