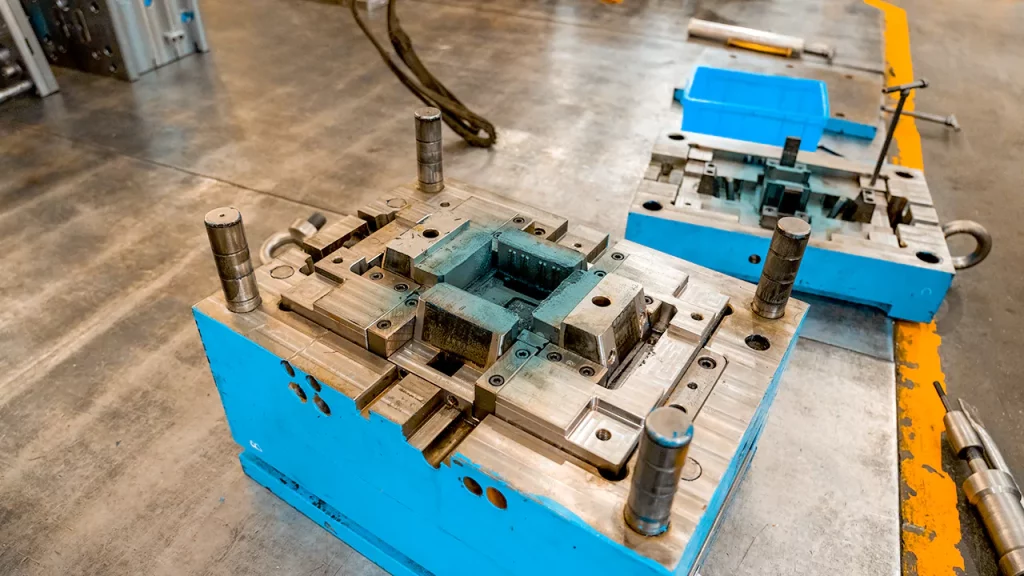

Rapid injection molding has the purpose of producing parts quickly. Proper design aids in ensuring that good parts are generated on the first run. Consequently, it is necessary to determine how the item will be put in the mold. The most important consideration is that the part remains in the mold half containing the ejector system. To do so, one must understand what a mold core and cavity are, how they differ, and where each fits in the injection molding process. Today we will discover everything about a mold core to conduct an effective injection molding manufacturing process. Please keep reading to learn all about mold core and how it differs from mold cavities.

What is a Mold Core?

Mold core, also known as the sand core, is the filler used to create the inner cavity shape of castings, and it comes in three varieties: inner sand core, outer core, and sand filling core. The inner sand core is used to create the inner cavity of the casting, and the outer core box supplements the sand core. The sand core is necessary for parts that cannot be drawn and manufactured directly.

The Difference Between Mold Core and Cavity in Injection Molding:

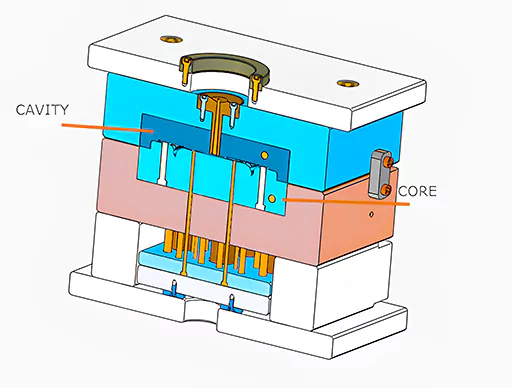

In the context of mold making, the mold core shapes the internal features of the part, while the mold cavity shapes the external features. They work together within the mold to create the desired shape and geometry of the final molded part.

However, it’s important to understand that a mold core and cavity are two distinct components that work together to create a molded part. Here’s how they differ:

Mold Core:

- The mold core is a solid or movable component within the mold that forms the internal features or voids of the final molded part.

- It represents the shape and geometry of the desired internal features of the part.

- The core is typically mounted or positioned inside the mold cavity and is responsible for creating the hollow or interior portions of the molded part.

- The core can be fixed in place or designed to move or retract to facilitate part ejection.

Mold Cavity:

- The mold cavity is the space or void within the mold that defines the external shape and features of the final molded part.

- It represents the negative or inverse of the desired part’s shape and geometry.

- The cavity is formed by the space surrounding the mold core.

- We inject the molten material into the mold cavity, filling it and taking the shape of the cavity and core to produce the final molded part.

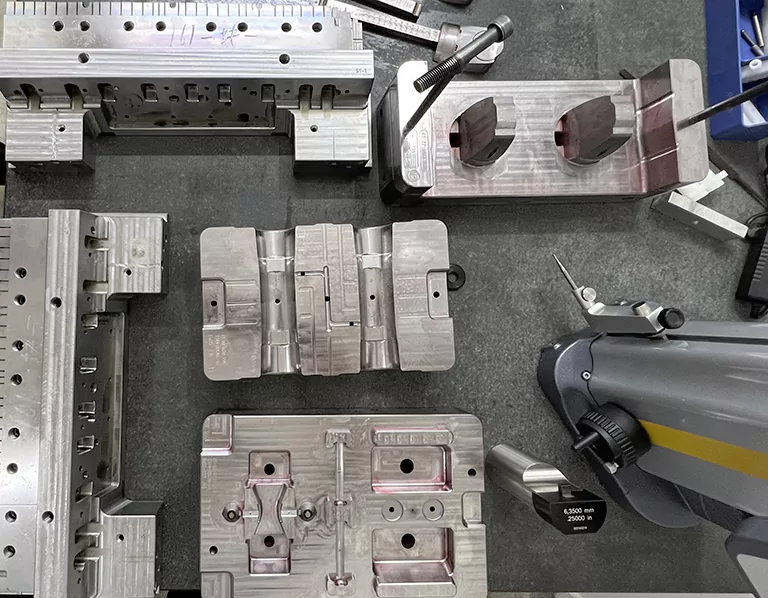

How To Inspect Mold Core Quality?

Once you understand what a mold core is and its importance in manufacturing high-quality products ready to use, it’s crucial to be familiar with ways to inspect the quality of the mold core.

Besides, if you don’t use high-quality mold core or maintain the core quality when using it in a plastic injection mold for manufacturing, it can result in defective and waste production.

Ways to prevent defective and waste production

1. Before using the depth micrometer, ensure it is thoroughly cleaned, and then examine its moving parts to ensure that they are both flexible and reliable. Specifically, the differential cylinder should rotate flexibly during the complete stroke, the differential screw should move steadily, and the locking device should function reliably.

2. Determine if the depth or height was measured first, then choose whether to replace or keep the measuring rod.

3. Use the 00-level platform to clean the platform, the datum plane, and the measuring surface of the depth micrometer. Rotate the differential cylinder to make its end face fall outside the zero line of the fixed sleeve. Stick the micrometer’s datum plane on the platform’s working surface, press the base with the left hand, and slowly rotate the ratchet with the right hand. The 0-25mm depth micrometer can directly check the zero position. So when the measuring surface has made contact with the working surface of the platform, check that the zero position is correct by ensuring that the zero graduation line on the differential cylinder is aligned with the vertical graduation line on the fixed sleeve and that the end face of the cone surface of the differential cylinder is tangent to the zero graduation line of the sleeve.

4. The zero position of depth micrometers with a measuring range of more than 25 mm must be checked using a check gauge (which can be replaced by a gauge block) in the following manner: the working surfaces of the check gauge and the platform must be wiped clean; the check gauge must then be placed on the platform; and the datum plane of the depth micrometer must then adhere to the zero position of the check gauge.

5. When using a depth micrometer to measure blind holes and deep grooves, the bottom of the hole or groove is frequently not visible; therefore, extreme caution should be exercised when operating the depth micrometer, and force should be applied only when necessary.

6. For measurements of holes with diameters or slot widths that are bigger than the base of the depth micrometer, an auxiliary positioning reference plate may be utilized in place of the base of the depth micrometer.

Common Mold Core Issues That Can Affect Production Quality:

As with any other component in manufacturing molds, mold cores are susceptible to the same problems that can affect the molded parts’ ability to perform their intended functions. Please learn the list of some of the most typical problems that can occur with mold cores:

Core Shift:

During the injection molding process, a phenomenon known as core shift can take place if the mold core moves or shifts from the position it was supposed to be in. This can lead to the final molded object having improper alignment or dimensional accuracy issues.

Sticking:

The term “sticking” describes the phenomenon in which, during the ejection process, the mold core remains lodged within the molded item. It may result from insufficient draft angles, inadequate release agents, or excessive friction between the mold core and the part material.

Warping:

Mold cores are susceptible to warping, particularly when they are put through conditions in which they are exposed to high temperatures and repeated pressure cycles. Warping can result in dimensional distortions, affecting the molded components’ accuracy and operation.

Cracking or Breakage:

Due to the tensions and pressures inherent in the injection molding process, mold cores made from less durable or unsuitable materials may exhibit a higher susceptibility to cracking or breaking compared to other mold components. Consequently, this can result in compromised part quality and substantial mold damage.

Wear and Tear:

The mold cores are subject to use and abuse whenever they are put through numerous cycles or used continuously. Over time, a core may suffer from abrasion, erosion, and fatigue, resulting in a decline in the surface quality, dimensional integrity, and overall performance of the core.

Problems Associated with Cooling:

Mold cores can experience issues associated with cooling, such as insufficient cooling or incorrect heat transmission. If there is not enough cooling, the cycle durations will be longer, the part quality will be poor, and there is a possibility that there may be warping or dimensional changes.

Problems with Venting:

Mold cores need correct venting to release any trapped air and gases during the injection process. When vents are inadequate or clogged, air can become entrapped, leading to surface flaws, voids, or an insufficient part filling.

Challenges in Maintenance:

To maintain their best performance, we should regularly clean, inspect, and maintain the mold cores. Inadequate maintenance of the mold cores over time might result in problems such as corrosion, contamination, or deterioration.

Also Read: Design Guide for Different Types of Industrial Molds

Conclusion

All in all, the mold core is critical in injection molding, and understanding its significance is critical when working with this manufacturing technique.

The mold core is responsible for sculpting the molded part’s internal features, such as intricate details, hollow portions, and complex geometries. It directly impacts the end product’s correctness, functionality, and quality.

Hence, injection molders can ensure proper design, location, and performance of the core within the mold cavity by thoroughly understanding the mold core.

Have more questions about mold core? Feel free to ask our experts at Prototool.com.