If you’re already familiar with the world of machining magnesium, you know it’s a fantastic lightweight metal that can be transformed into strong, corrosion-resistant parts through CNC techniques.

However, delving deeper into magnesium machining reveals its advantages and unique challenges. The potential for ignition or explosion due to its flammable chips and dust is a concern that demands proper precautions.

In this article, we’ll explore the finer details of machining magnesium, uncovering its benefits, taking you through the different machining considerations, and addressing the essential safety practices that elevate your magnesium machining expertise.

Don’t forget to check out our machining part guide for more in-depth insight into the modern-day machining process.

The Evolution of Magnesium Machining

In recent years, people have become more interested in using magnesium. This interest is mainly because of its lightness, which is important for making things like cars lighter.

But magnesium is also used in other areas like airplanes, electronics, medicine, and sports gear. So, learning how to work with magnesium, called machining magnesium, has become a big deal for experts and researchers.

Why Machining Magnesium is Beneficial?

When working with metals, using magnesium has some cool benefits. Magnesium is the lightest metal used to build things and is super easy to shape. This makes it different from metals like stainless steel and titanium. Now, let’s further explore why using magnesium for machining is a big deal:

- Efficient Power Usage: Compared to metals like aluminum, machining magnesium demands only about 55% of the power, making it an energy-efficient choice.

- Speedy Machining: With high cutting speeds, generous feed rates, and deep cuts, magnesium machining takes the lead in efficiency, even against formidable contenders like stainless steel or titanium.

- Exceptional Surface Finish: The result? A remarkably fine and smooth surface finish, a feature that outshines the outcomes achieved with other metal types.

- Tidy Chip Breakage: The innate ease of cutting magnesium results in tidy chip breakage, offering a cleaner process than many other metals.

- Longer Tool Life: Reduced tool wear translates to prolonged tool life – a standout advantage akin to the benefits observed when machining materials like titanium.

It’s important to know how magnesium works to make the most of these benefits. When you understand its special qualities, you can use magnesium fully when shaping metal. This makes magnesium machining a smart addition to your metalworking skills.

Why Opt for Magnesium in CNC Machining?

Considering the potential risks of CNC machining involving magnesium, you might wonder why you chose this material. It’s a valid question. However, with proper adherence to safety guidelines, magnesium can be an excellent choice for CNC machining.

This lightweight structural metal boasts exceptional surface finish and machinability, making it a compelling option for various applications. Let’s explore why selecting magnesium for CNC machining can be smart.

Superb Machinability

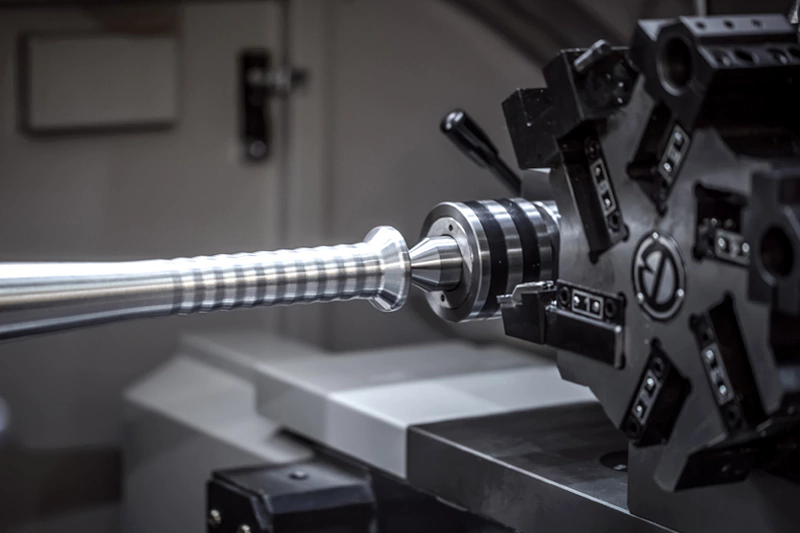

Machining magnesium with CNC processes is notably easier due to its remarkable machinability. Magnesium alloys exhibit lower cutting forces, which helps reduce the cutting tool wear rate. This makes CNC machining of magnesium smoother, minimizing tool maintenance and replacement.

Complex Geometries

The high machinability of magnesium alloys makes them perfect for crafting custom parts with intricate geometries.

CNC magnesium machining excels at producing components featuring precise and complex features, meeting the stringent requirements of modern engineering projects. Multi-axis CNC machines enhance this capability by enabling machining from various angles, ensuring microscopic precision, and meeting diverse project needs.

Recyclability

One of the standout advantages of magnesium is its recyclability. Magnesium alloys are environmentally friendly and can be recycled, aligning with sustainable manufacturing practices. This makes magnesium an ideal material for reducing environmental impact.

Additionally, CNC machining generates magnesium waste, which can be recycled, contributing to a more eco-conscious production process.

By understanding these reasons, you can see how magnesium’s machinability, suitability for intricate designs, and recyclability make it a valuable choice for CNC machining despite the associated safety considerations.

Considerations when Machining Magnesium

When it comes to machining magnesium, there are several important things to keep in mind. Let’s break down these considerations step by step:

Cutting Power and Machinability

- Magnesium’s cutting power, or how much energy it takes to cut it, is much lower than metals like aluminum.

- This means less stress on tools, allowing higher cutting speeds and feed rates.

- The energy needed to remove a certain amount of magnesium is lower than other metals.

- Different metals have varying machinability. For instance, magnesium alloys are easier to machine than mild steel or titanium.

Speeds, Feeds, and Depths of Cut

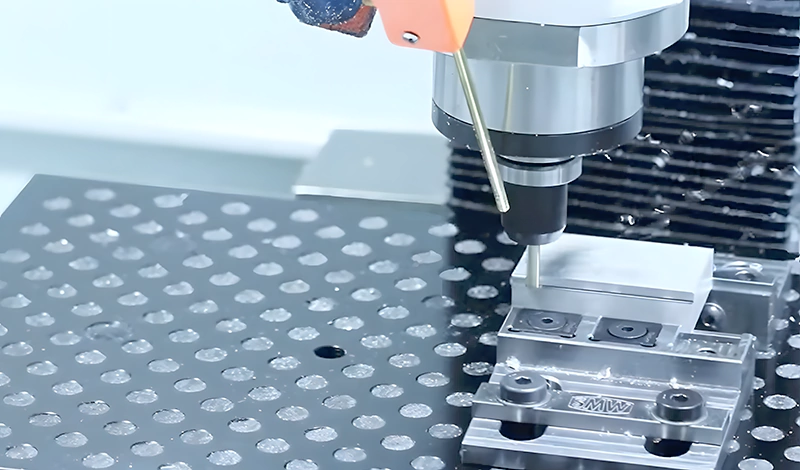

- Factors like component stability and tool rotation speed often limit high-speed machining of magnesium alloys.

- For turning, boring, and similar operations, cutting speeds are generally between 200 – 1800 m/min with feed rates greater than 0.25 mm/rev.

- Face milling can be done at even higher speeds, up to 3000 m/min, with specific feed rates.

- Depths of cut can be as deep as 12 mm, but some operations like drilling and tapping require different approaches.

- Using proper feeds ensures well-broken chips, which are safer and more efficient in magnesium machining.

Tooling

- The tools used for machining aluminum can also work for magnesium, but some adjustments are needed.

- Carbide is popular due to its wear resistance and good surface finish, while polycrystalline diamond (PCD) is used for superior surface quality.

- PCD tools are highly wear-resistant and prevent built-up edges (BUE) on the tool.

- Uncoated carbide tools are also recommended for magnesium machining, offering sharp cutting edges and cost advantages.

By considering these considerations, you can ensure successful and safe machining of magnesium, optimizing its unique properties for your machining needs.

To understand the additional parameters when machining magnesium, especially compared to other metals, refer to the table below.

| Metal | Turning Rough (m/min) | Turning Finish (m/min) | Milling 100 mm miller 1 mm cut m/min | Drilling (5-10 mm drill) m/min |

| Magnesium | Up to 1200 | 1800-2400 | 200-500 | 150-500 |

| Cast Iron | 30-90 | 60-120 | 15-20 | 10-40 |

| Aluminum | 75-750 | 120-1200 | 200-300 | 60-400 |

| Steel | 40-200 | 60-300 | 20-25 | 15-30 |

Important Tips For Machining Magnesium Safely

Taking the right precautions is essential when safely machining magnesium through CNC precision processes. Here are detailed tips to ensure safe machining of magnesium:

Maintain Proper Tooling Condition

When dealing with magnesium machining, the condition of your cutting tools matters a lot. It’s essential to use sharp cutting tools to minimize risks. Dull tools can generate a lot of heat, which can be dangerous, as it might cause the chips produced during machining to catch fire.

Instead, it’s better to use carbide-tipped tools, as they stay hard even at high temperatures, reducing the chances of sparks that could lead to ignition.

Avoid Tight Clearance Angles

It’s best to steer clear of tight clearance angles in magnesium alloy machining. While you might be tempted to machine at higher speeds, tight angles can lead to longer, unbroken chips. These chips can get entangled with the rotating cutting tool, generating excessive heat.

Given that magnesium alloys are highly flammable, this can result in a severe fire hazard. So, play it safe and avoid those tight angles.

Make Discontinuous Chips

When you’re busy with CNC machining magnesium, keep a close eye on the chips produced. It’s a good idea to aim for what’s called “discontinuous chips.” These are chips that are broken up, almost like puzzle pieces.

Why? Because these chips help dissipate heat effectively, reducing the risk of ignition. Program your cutting tools with a small back rake angle to get these chips. Then, use low feed rates and moderate to high cutting speeds. Larger cutting depths can also help create these desirable chips.

Avoid Water-Based Coolant

In magnesium CNC machining, heat can become a concern if you’re not careful. To keep things under control, avoid using water-based coolants. Instead, go for mineral oil coolants.

These coolants reduce the chances of fires and explosions and enhance the quality of the surface of the magnesium parts you’re machining. Why avoid water-based coolants? They can react with magnesium, producing highly flammable hydrogen gas.

Use an Explosion-proof Vacuum for Chips

Even if you’ve done everything right with your magnesium machining parameters, the chips left behind can still be hazardous. To tackle this, advanced CNC machine shops use an “explosion-proof vacuum system.” This system safely removes magnesium chips and dust from CNC machines. It’s an extra safety step to ensure no potential risks are left behind.

Never Quench with Water

If, by any unfortunate chance, a magnesium fire breaks out while you’re machining, don’t even think about using water to put it out. Water can make the fire worse. Instead, grab dry, Class-D fire extinguishers. They’re the right tools to quickly handle a magnesium fire. If it’s a small fire you’re dealing with, dry sand is a simple but effective alternative.

By paying close attention to these safety tips, you can confidently navigate the world of machining magnesium, enjoying its benefits while keeping potential hazards at bay.

——

As professionals with decades of experience in CNC machining and custom parts production services, we at Prototool are always available to handle your next magnesium machining project per your requirements.

Get a quote today!