The aerospace industry encompasses the research, development, and manufacturing of an array of aircraft and spacecraft products, such as commercial and military aeroplanes, helicopters, and gliders, as well as spacecraft, launch vehicles, satellites, and other space-related objects. Flying in the earth’s atmosphere is not as easy and simple as moving on the ground. Whether for commercial air travel, space aviation, or the defence sector, the quality and durability of aerospace parts and structures must be taken into account. It needs the utmost skills and ability to produce complex geometries of aircraft parts with high precision. There is no room for human error. This is where CNC machining Aerospace parts come into play.

Before going into details, let’s develop a basic understanding of CNC machining in aerospace.

What is Aerospace CNC Machining?

Aerospace CNC machining is a process in which computer-enabled tools and parts are created to assemble and maintain aircraft and space shuttles. However, aircraft move at high speeds and are required to be resilient and sturdy even in complex weather. That’s why aerospace CNC machining is highly recommended.

As the name suggests, Computer Numerical Control (CNC) is a computerized manufacturing process in which pre-programmed software and code control the movement of production equipment.

Aerospace machining is the creation of parts used in assembling and maintaining air and space vehicles. However, the aerospace industry is the most sensitive sector using the application of CNC. Accuracy is the primary key because money and human lives are at stake. It cannot afford a one-minute error. For a single piece or thousands of pieces, with CNC machines, you can get the same results without any incongruity unless there is similar drafting of the initial prototype.

Importance of CNC application in the aerospace industry

CNC machining occupies a special place in the aerospace manufacturing world for the following reasons:

Achieve High-Level Accuracy

Now you can attain a high level of precision and accuracy with CNC machining to manufacture various aircraft components. However, the aerospace industry hires other manufacturers to get different components. These components must ensure tight tolerances and buy precise components from other machine shops.

Aerospace CNC machining manufacturers use kits, components, and various assemblies, which are vital for crafts in the aerospace industry. They manufacture the components fastidiously as specified and deliver tolerances as small as 4μm. You can bear a failure of the part in any other industry, but it’s not an option in flight. Hence, CNC machining delivers unparalleled precision.

CNC Machining application in Aerospace Aviation

The utmost requirement for designing and manufacturing an aircraft is accuracy. Whether it’s a fighter jet, cargo plane, or commercial airline, all demand resilient outer shells and innermost layers.

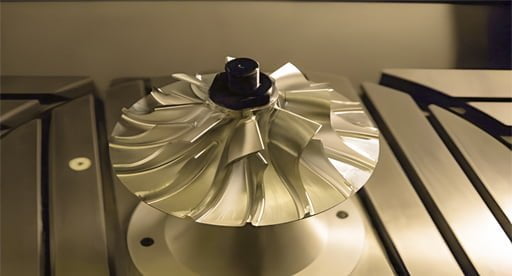

The engine is the most fundamental component in an aircraft for the exterior portion. Thus it ensures there should be no leakage or any component malfunction while processing and burning fuel. Aerospace CNC machining manufacturers help to produce the most intricate parts essential to the engine’s efficient operation.

CNC machining is equally important for the interior parts of aircraft. It plays a vital role in designing the cockpit. Some tiny interlinked parts make up the navigational system that gives directions to the pilots in actual time.

This new machining technique helps construct these tiny CNC machining aerospace parts, which might involve refinement and modification from time to time. CNC machined parts increase extreme precision and substantial endurance to avoid any failure.

CNC Machining application in Space crafts

Various space travel agencies, including NASA and SpaceX, meticulously design and construct the most scientifically advanced rockets and spaceships for different deep-space missions.

In this scenario, CNC aerospace machining does wonder. This process is crucial to manufacturing microscopic parts that lead to the rocket’s body design. Aerospace CNC machined parts thus operate without failure and also ensure the safety of spacecraft and crew members. Since space travels demands longevity and no scope of human error, CNC machining has been prevailing rapidly in this sector.

So let’s see the common but crucial aerospace metal parts that can be generated using CNC Machining. Take a look:

Aerospace CNC machined parts

The aerospace industry has incorporated CNC machining because of its critical safety reasons. It has shared a long history of using this application. A high level of precision is the basic requirement for machining metal aircraft components. With the advent of CNC-compatible engineering metals, engineers have plenty of options. CNC machining has been used widely in the aerospace sector. Some of the aerospace CNC machined parts are enlisted below:

- Engine mounts

- Fuel flow components

- Landing gear components

- Fuel access panels

Aerospace Machining Materials

Strong and Resilient Plastic Components

CNC Aerospace Machining generates strong, resilient, lightweight, and multifaceted plastic parts for the aerospace industry. The materials used for manufacturing these parts are PEEK and other high-performance polymers. PEEK stands for PolyEtherEtherKetone. It is the highest-performing thermoplastic semi-crystalline polymer. It is widely used in the aerospace industry. It replaces metal alloys in various structural and geometrical applications. Since it is lightweight and highly chemical-resistant thermoplastic, it has gained popularity in many sectors, specifically in the aerospace and defence industries. It is an ideal choice for machined lightweight aircraft components.

Light Weight Metal Parts

Due to their immense strength, aluminium and titanium are the most choices of metals used in the aerospace industry. These metals are popular and dominant because they are lightweight compared to steel or any other metal. Light-used metals used in aircraft enhances fuel consumption and overall performance.

However, the manual machining of these metals is tiresome and laborious. This is where CNC Aerospace Machining aids the aerospace industry by delivering compatibility with a wide variety of materials and offers seamless construction of both these metals.

CNC Application in Prototyping

CNC Machining does not only play an important role in manufacturing various aircraft components. It also helps in research and development. CNC machines work on taking instructions from 3D CAD models to manufacture various parts. It allows aerospace engineers to develop new prototypes and test and edit them in real time beforehand.

This type of prototyping is suitable and economical for aerospace companies as it lessens expenses and also saves time. It maximizes the return on investment by purchasing more tools. Besides this, it also enables aerospace companies to fulfil regulatory requirements, such as AS9001 and ISO 9001:2015 standards.

Complex Design Construction

The aerospace industry highly demands the manufacturing of complex designs of aircraft components. NASA’s Orion bulkhead, for example, a component that assures crew safety, has a dome configuration near the heat shield. It has pockets normal to its surface.

CNC Milling Machines

Another example is the considerable size of the aircraft’s landing gears and fuselage sections. These designs require tiny details and call for extremely high tolerance. With 5-axis CNC milling machines, you can produce even the most complex parts. These machines can only deliver reaches and angles you might not attain using 3- or 4-axis machines. In CNC milling machines, the tool spins at high speeds.

CNC aerospace machining gives the most accurate and cost-effective results. Automated manufacturing has increased the pace of using parts, components, and structures that all need different machining, moulding, and additive manufacturing levels. The biggest aircraft, Boeing 747, for instance, comprises 6 million separate parts.

CNC Turning Process

In the production process of CNC turning, material bars are held in the form of a wedge, and they will be rotated while a tool is fed to the piece to remove materials until the required form or structure is attained. Subtraction machining is another name for this process, which involves removing material in order to create the desired shape.

Conclusion

After digging into minor details of CNC machining, you will now understand the importance of its application in the aerospace industry. It requires state-of-the-art designs and structures that comply with industry standards. The delicacy and intricacy involved in the utilization of aircraft and spacecraft make it significant to use high-grade components. However, only Aerospace CNC machining can deliver these highly durable and precise components.

CNC machining is more time-efficient for aerospace engineers to make changes and conduct testing, in addition to providing extremely high precision and tolerance. To acquire the best CNC machine for your money, it is recommended to do extensive research before making your decision.

The most recent and technologically advanced CNC machines used in the aerospace sector have Artificial Intelligence (AI) software that has been supplemented.

This combination has made it possible for aerospace companies to establish precise production metrics and easily meet production targets for aircraft parts. Additionally, it has enhanced the durability and quality of machined aerospace components.

Are you still perplexed about the use of CNC machining? Are you in search of CNC aerospace machining services? No worries! Prototool is here. Now you can boost your aircraft’s accuracy, precision, and longevity by availing of our CNC machining services.