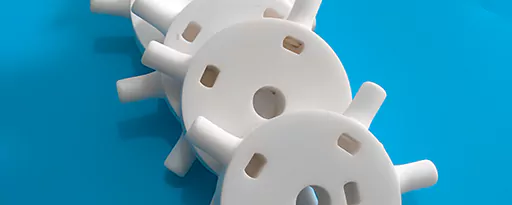

Ceramic manufacturing is a complex and fascinating process that involves using advanced materials and techniques to create a wide range of products, from household items to high-tech components for aerospace and defense applications. One of the most popular methods for ceramic manufacturing is injection molding, which allows for creating of complex shapes and designs with high precision and repeatability. This article will provide a step-by-step guide on how ceramic is used to manufacture different products through the injection molding process.

Properties of Ceramic Materials:

Below are the properties that make ceramic manufacturing a standard and highly opted manufacturing solution:

Hardness:

Ceramics are tough and highly resistant to wear and tear. They can withstand high pressure, stress, and temperature changes without deforming or breaking. This makes them ideal for cutting tools, bearings, and other industrial applications.

High-Temperature Resistance:

Ceramics can withstand extremely high temperatures without melting or degrading, making them ideal for high-temperature applications such as furnaces, kilns, and gas turbines.

Chemical Resistance:

Ceramics are highly chemical resistant and can withstand exposure to acids, alkalis, and other corrosive substances. This makes them ideal for chemical processing, water treatment, and harsh environments.

Electrical Properties:

Ceramics have excellent electrical properties, including high insulation resistance and low dielectric loss. This makes them ideal for electronic applications such as capacitors, resistors, and insulators.

Biocompatibility:

Ceramics can be used in medical and dental applications such as dental implants, joint replacements, and bone grafts.

Common Applications of Ceramic Materials in Manufacturing:

Although ceramics is a commonly used product involved in manufacturing products that we find in our day-to-day lives, specific professional industries are fonder of ceramic manufacturing for their products. These industries and their products include:

- Aerospace and Defense: Ceramics are used extensively in the aerospace and defense industry due to their high strength, durability, and heat resistance. It helps produce components like missile nose cones, turbine blades, and engine components.

- Electronics: Ceramics are used in the electronics industry to manufacture capacitors, resistors, and other electronic components due to their excellent electrical properties.

- Medical: Ceramics are used in medical and dental applications such as dental implants, bone grafts, and joint replacements due to their biocompatibility.

- Automotive: Ceramics are used in the automotive industry to manufacture catalytic converters, engine components, and brakes due to their high-temperature resistance and strength.

- Energy: Ceramics are used in the energy industry to manufacture fuel cells, solar panels, and other components due to their high-temperature resistance and electrical properties.

10 Amazing Benefits of Opting for Ceramic Manufacturing:

Ceramic manufacturing creates products from clay, silica, feldspar, and other raw materials. This process has been used for thousands of years, and modern technology has allowed the development of even more advanced ceramic products. There are numerous benefits of ceramic manufacturing that make it a popular choice for various applications.

Durability:

One of the most prominent benefits of ceramic products is their durability. Ceramic materials are highly resistant to wear and tear, making them ideal for harsh environments. They are also corrosion-resistant and can withstand high temperatures, making them suitable for use in industrial settings.

Versatility:

Another benefit of ceramic manufacturing is its versatility. Ceramics can create a wide range of products, from everyday items like mugs and plates to specialized components used in aerospace and medical applications.

Environmental Sustainability:

Ceramic products are often more environmentally sustainable than plastic or metal. They are made from natural materials, allowing recycling and compositing at the end of their useful life.

Aesthetic Appeal:

Ceramic products are famous for their aesthetic appeal. They can be shaped and glazed in various ways, allowing for unique and visually appealing designs.

Thermal Insulation:

Ceramic materials are excellent insulators ideal for heat-resistant applications. You can find them in furnace linings, kiln components, and high-temperature filters.

Chemical Resistance:

Ceramics are also highly resistant to many chemicals, making them useful in applications where other materials are quickly eroded or degraded.

Biocompatibility:

Many ceramic materials are biocompatible, meaning you can safely use them in medical implants and other biological applications.

Low Maintenance:

Ceramic products are often low maintenance, requiring little or no upkeep over their lifespan. This makes them an attractive option for applications where regular maintenance could be more practical.

Cost-Effectiveness:

While the initial cost of ceramic products may be higher than some other materials, their long lifespan and durability can make them more cost-effective in the long run.

Electrical Properties:

Ceramic materials have a range of electrical properties, making them useful in applications ranging from insulators to conductors. You can find them used in electronic components such as capacitors and resistors.

All in all, ceramic manufacturing offers numerous benefits that make it an attractive option for various applications. Ceramics are widely used and appreciated for their durability, versatility, aesthetic appeal, environmental sustainability, thermal insulation, chemical resistance, biocompatibility, low maintenance, cost-effectiveness, and electrical properties.

Ceramic Manufacturing Process Requirements and Considerations:

Some of the essential technical requirements and procedures that should be considered during ceramic manufacturing include the following:

Material Selection:

The selection of the appropriate ceramic material is critical to the success of the manufacturing process. Here, the key factors to consider are the material’s properties, cost, availability, and compatibility with other components.

Powder Preparation:

Careful preparation of ceramic powders is crucial to ensure consistent particle size distribution, purity, and flow properties. Professionals use milling, spray drying, and calcination techniques to prepare ceramic powders.

Binder System:

The binder system used in ceramic manufacturing plays a crucial role in shaping and forming the product. The binder system should have the necessary rheological properties to allow for uniform flow during molding and should be compatible with the ceramic material you use.

Molding:

Molding is a critical step in ceramic manufacturing, and several factors must be considered, including mold design, temperature, pressure, and time. Optimizing the molding process is crucial to ensure the product has the desired shape, dimensions, and surface finish.

Debinding:

After molding, the product must be debonded to remove any organic materials, such as binders or lubricants, that professionals add during the manufacturing process. It’s vital to conduct debonding carefully to prevent cracking, warping, or other defects in the product.

Sintering:

Sintering is a critical step in ceramic manufacturing that involves heating the product at a high temperature to achieve the desired mechanical and thermal properties. Optimize the sintering process so that the development and its consistent microstructure densify correctly throughout.

Quality Control:

Quality control procedures should be in place to ensure that the product meets the desired specifications and standards. This may involve testing the product for mechanical, thermal, or chemical properties or conducting visual inspections to detect defects.

Environmental Considerations:

Ceramic manufacturing can generate significant amounts of waste and pollution. Therefore, ecological considerations, such as waste management, energy efficiency, and emissions reduction, should be considered throughout manufacturing.

Tips to Ensure Quality Ceramic Product Manufacturing:

The following are some crucial tips to consider to ensure quality ceramic manufacturing:

Proper Material Selection:

The suitable ceramic material is vital for manufacturing quality. The material should have the appropriate mechanical, thermal, and chemical properties for the intended application. Manufacturers should thoroughly analyze the material’s properties and characteristics to meet the required specifications.

Proper Preparation of Ceramic Powder:

Preparing the ceramic powder is a critical step that requires attention to detail. Prepare the powder with a consistent particle size distribution and free from contaminants. It’s also important to carefully monitor the milling or spray-drying process to ensure the powder is of the desired quality.

Proper Binder System:

The binder system used in ceramic manufacturing should be compatible with the ceramic material used. It’s essential to carefully monitor the viscosity and flow properties to ensure the mixture flows evenly during molding. The binder should also be easily removable during the debonding process to avoid defects in the final product.

Molding Process Optimization:

The molding process should be carefully optimized to ensure the product has the desired shape, dimensions, and surface finish. Carefully consider the mold design and closely monitor the molding process to ensure product formation without defects or voids.

Controlled Debinding Process:

The debonding process is a critical step that requires careful control to avoid defects in the final product. Ensure to fully monitor the temperature, time, and atmosphere conditions to properly remove the binder without damaging the ceramic material.

Controlled Sintering Process:

Sintering is critical in achieving the final product’s desired mechanical and thermal properties. It’s essential to carefully control the sintering temperature, time, and atmosphere conditions to ensure the complete densification of ceramic particles without causing defects in the final product.

Quality Control Procedures:

Quality control procedures should be in place throughout manufacturing to ensure the product meets the desired specifications and standards. This may involve testing the product for mechanical, thermal, or chemical properties or conducting visual inspections to detect defects.

Continuous Improvement:

Continuous improvement is a critical component of quality ceramic manufacturing. Manufacturers should continually evaluate and optimize their manufacturing processes to produce high-quality products efficiently and effectively.

Conclusion:

In the end, once you understand the complexities of ceramic product production, with careful optimization of each step, ceramic injection molding can produce high-quality and complex ceramic products with excellent mechanical, thermal, and chemical properties.