As a flexible thermoplastic polymer (Check the thermoplastic manufacturing), ABS is used in various applications, from automotive components to consumer goods. This material has a wide range of applications, including ABS Virgin and specialty grades, and it has good mechanical qualities and durability. Because of its low melting point, ABS is particularly well-suited for machining processes.

But is that enough to consider during ABS machining? Definitely not! From challenges to applications and additional insights, there is much to consider during ABS machining. In this article, we will take you through all that and more. So, keep reading to learn how to effectively conduct a precision ABS machining process.

Before you delve deeper into it, we also suggest you go through our detailed guide on machining parts.

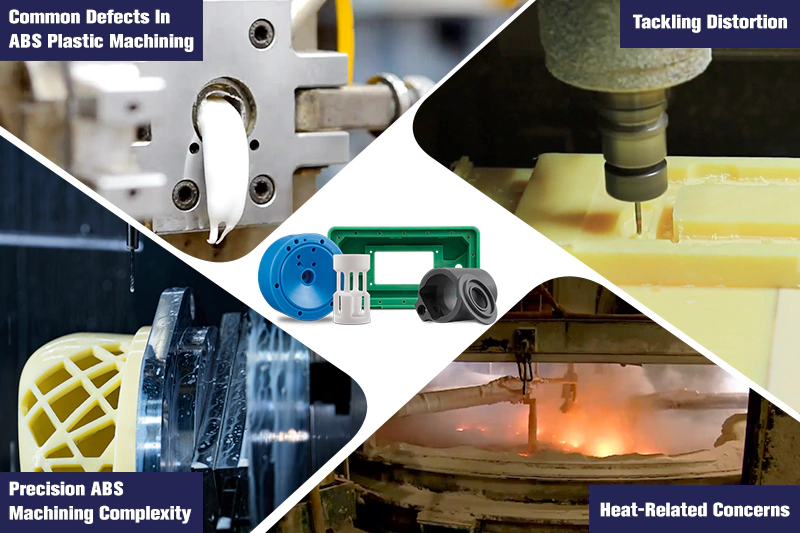

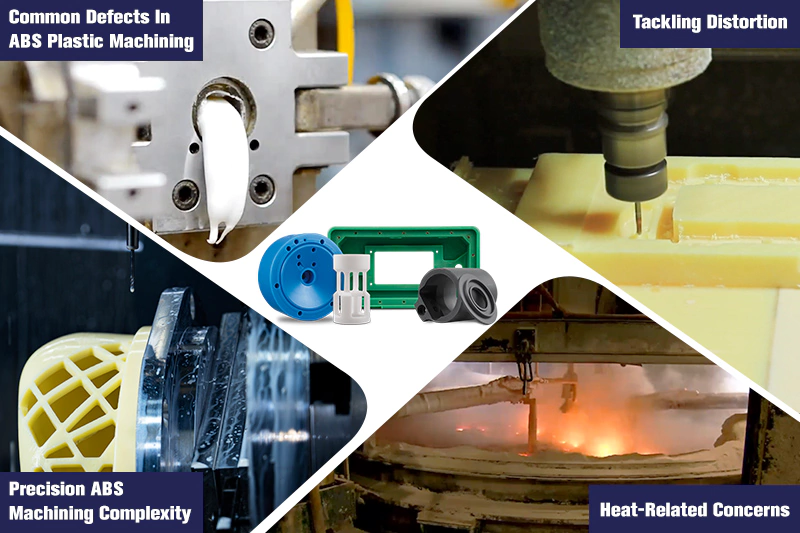

Understanding the ABS Challenge: Precision Meets Delicacy

Before delving into the intricacies of ABS plastic machining, it’s crucial to understand this versatile material’s unique challenges. Let’s take a closer look at them below:

Precision ABS Machining Complexity

Crafting high-quality, precision-machined parts from ABS plastic demands the right equipment and expertise. Even experienced machinists can face hurdles when handling ABS plastic, especially without the proper understanding. Sometimes, the realization of a damaged ABS plastic part only dawns after the workpiece is completed.

Common Defects in ABS Plastic Machining

Like other machined plastics, ABS plastic often exhibits two common machining defects: distortion and a subpar surface finish. Parts marred by tooling marks or chatter lines won’t meet surface quality requirements. Additionally, any scratches and imperfections can render transparent ABS parts cloudy or lead to leaks in ABS fittings during ABS material processing.

Surface Quality Challenges

Surface quality issues in ABS plastic components can arise from various factors. Using the wrong cutting tools, incorrect cutting parameters, or allowing excessive heat buildup are common culprits that can compromise the surface finish of ABS parts.

Tackling Distortion

Another prevalent challenge in working with ABS plastic is avoiding distortion. Unlike commonly machined metals, ABS plastics exhibit significant thermal expansion when heated. This can lead inexperienced machinists to remove excessive material, becoming evident when the part cools and contracts.

Heat-related Concerns

To complicate matters, ABS plastics boast relatively low heat deflection temperatures and thermal conductivities. Consequently, heat can accumulate rapidly during ABS material processing, causing the plastic to soften and deform.

Tips for Effective ABS Machining

In ABS manufacturing, you can elevate your results by implementing several tried-and-true techniques. These tips are essential to ensure the quality and precision of your ABS machined parts. Whether you’re engaged in ABS fabrication or ABS plastic machining, these strategies will prove valuable.

#1 – Opt for Machine-Grade ABS Plastic

ABS plastic comes in various grades, each tailored for specific applications like extrusion, casting, or ABS CNC machining. Always opt for machine-grade ABS plastics for tasks such as ABS CNC milling, turning, or drilling. This choice ensures optimal chip formation and delivers a superior surface finish.

#2 – Select Appropriate Cutting Tools

Choosing the right cutting tools is paramount. While those designed for machining high-strength metals may excel in other contexts, they are ill-suited for ABS plastics. Knowledgeable machinists understand the importance of employing cutting tools specially crafted for plastics. Maintaining the sharpness of these tools is equally crucial to prevent damage to the plastic’s surface.

#3 – Fine-Tune Your Cutting Parameters

ABS CNC Machining depth matters significantly. Cutting too deep or shallow in a single pass can lead to part deformation or machining chatter. Similarly, improper cutting speed or feed rate can result in excessive heat buildup, distorting your ABS components. Though determining the ideal cutting parameters often requires experience, the enhanced quality of your machined parts makes this effort worthwhile.

Additionally, ensure that your machining setup securely holds the ABS part in place without over-compressing it, as excessive pressure can distort the final product.

#4 – Employ an Appropriate Coolant

During machining, ABS plastic can overheat and deform if not properly cooled. However, it’s crucial to use the right type of coolant. While ABS plastics generally exhibit good chemical resistance, certain coolants designed for metals or ceramics can lead to contamination.

For machining plastic parts, it’s advisable to utilize a non-aromatic, water-soluble coolant specifically designed for this purpose. Plastic coolants can be applied as a pressurized gas jet, a continuous mist, or a flowing liquid, depending on the coolant used and your part’s design.

#5 – Perform Annealing

Consider annealing your ABS plastic before precision ABS machining to mitigate potential issues. Unannealed plastic parts may harbor significant internal stresses that are not readily apparent in the raw material. When heated during machining or in service, these stresses can deform the final product, causing it to deviate from the desired tolerances.

Annealing ABS plastic is like gently baking it in an oven. We slowly warm it up to a specific temperature, keep it at that temperature for a while, and then let it cool down slowly. This process effectively relieves internal stresses, ensuring the integrity of your machined ABS parts.

Surface Finish Choices for ABS Machined Parts

The initial finish of CNC-machined ABS parts typically leans towards a matte texture. However, you can refine this surface after ABS material processing to achieve your desired appearance. Here, we’ll delve into some common methods for enhancing the finish of ABS components.

- Bead Blasting: Bead blasting is a favored technique for refining ABS surfaces. This process employs abrasive particles like sand, glass beads, steel, silicon carbide, and more. As these particles impact the ABS surface, they create a smooth, matte texture that greatly enhances the visual appeal of the part.

- Metallic Coating: To infuse a metallic sheen into your ABS parts, electroless and immersion plating are viable options. These methods enable the application of various metals onto the ABS surface. Common choices include aluminum, zinc, and other metals. This coating adds a metallic gleam, enhancing the part’s durability and resistance.

- Painting: Regarding surface finishing for CNC-machined ABS parts, adhesive painting is a popular choice. This method offers the versatility to paint the ABS surface in any desired color, catering to specific requirements. Moreover, if you’ve bead-blasted the ABS part before painting, you’ll achieve even more remarkable results. This combination provides an excellent finish that looks good and ensures the durability of your ABS components.

Applications of ABS CNC Machining

As previously said, ABS can be transformed into useful components for various industries, including automotive, electronics and electrical, aerospace, household appliances, defense, toys, and others. You can refer to the table below to evaluate the different applications of ABS manufacturing:

| Industry | Applications |

| Automotive | CNC-machined ABS plastics are crucial in the automotive industry, used in protective bumpers, steering and suspension parts, driveline spares, decorative interiors, wheel covers, and more. |

| Medical | CNC-machined ABS plastics are widely utilized in the medical field for nebulizers, compressors, pharmaceutical packaging, ultrasound equipment, drug delivery systems, lab equipment housing, and more. |

| Fitting & plumbing | CNC-machined ABS plastics are crucial for producing components like tubing, fittings, pumps, sockets, and more in fittings and plumbing. |

| Electronics & Electrical | CNC-machined ABS plastics are used for a wide range of applications, including enclosures, insulators, computer keyboards, power plugs, and power-tool housings. |

| Home Appliances | CNC-machined ABS plastics are crucial in home appliances, including refrigerator liners, vacuum cleaner components, kitchen utensils, gardening tools, toys, and more. |

| Defense | CNC-machined ABS plastics serve critical roles in the defense industry, producing protective headgear, hard hats, defense pads, and more. |

| Food processing | CNC-machined ABS plastics have diverse applications in the food processing industry, from refrigerator liners and juice presses to packaging, food processors, ovens, and food dryers. |

| Other | Lastly, CNC-machined ABS plastics are also used to create parts for musical instruments, furniture components, decorative items, and more. |

Conclusion:

In conclusion, ABS machining offers various applications and advantages, making it a valuable choice in various industries. Whether you’re looking for precision ABS CNC milling or ABS plastic fabrication, Prototool is a trusted partner in the manufacturing industry, ready to meet your specific needs with expertise and quality.

FAQs:

Can ABS Plastic Be Machined?

Absolutely! ABS plastic, a cost-effective engineering material, is eminently machinable. This thermoplastic polymer is frequently employed in pre-injection molding prototypes. If you’re looking for production-like parts with meticulous detail and robust mechanical properties, ABS CNC machining is a fantastic choice.

Where Is CNC Machined ABS Plastic Commonly Utilized?

CNC-machined ABS plastic finds its way into various applications thanks to its versatile characteristics. Some common uses include:

- General Purpose ABS Prototyping: ABS plastic excels in general-purpose ABS prototyping due to its ease of machining and cost-effectiveness.

- Pre-Molding Prototypes: It’s an excellent choice for crafting pre-molding prototypes, enabling you to refine designs before proceeding to full-scale production.

- Impact-Resistant Parts: ABS’s inherent toughness makes it ideal for parts that endure impacts, ensuring durability in such scenarios.

- Cost-Efficiency: When cost considerations are paramount, ABS plastic comes to the forefront as a budget-friendly yet highly functional material.