Feinabstimmung Ihrer CNC-Projekte: Ein Leitfaden für die Fertigbearbeitung

Surface finish or finish machining, a critical aspect of machining, delves into the fine details of perfecting a workpiece’s external quality and functionality. This precise process involves a meticulous surface adjustment, either by material removal or addition, to meet the highest standards of appearance and performance. If you’re already acquainted with the fundamentals of finishing […]

Optimierung der Produktion durch Halbfertigbearbeitung in der Zerspanung

The manufacturing industry highly values the role of semi-finishing. This crucial process involves refining a product to a specific level of completion before reaching the final finishing stage. It is pivotal in ensuring the end product meets the required specifications and standards, enhancing quality and aesthetics. Various industries, from automotive parts to aerospace components and […]

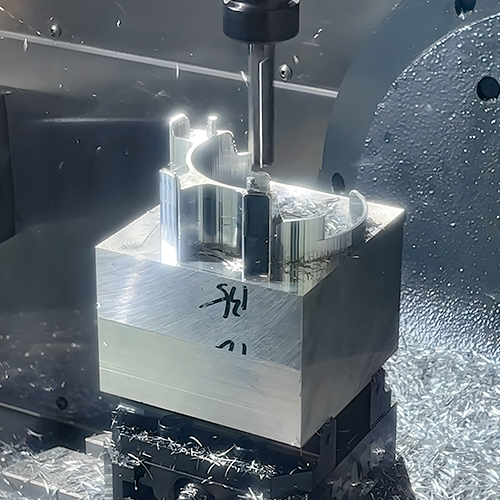

Vom Rohzustand zum Feinzustand: Erkundung von Rohbearbeitungsmethoden

Rough machining is a process that involves swiftly and efficiently eliminating excess material to bring your workpiece one step closer to its final design. This CNC machining approach employs larger cutting tools, making broad and powerful cuts to eliminate any unwanted material from a workpiece quickly. The result may be a coarser surface finish, but […]

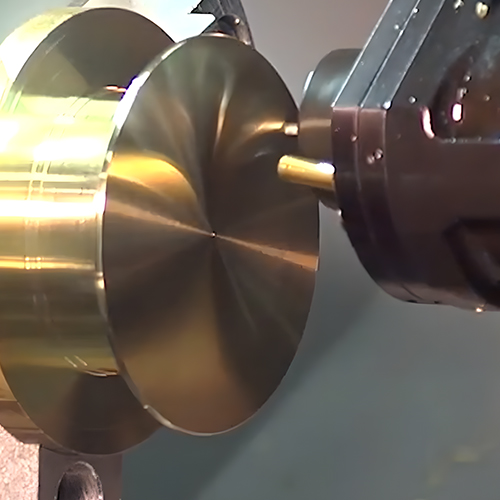

Umfassender CNC-Leitfaden für die Bearbeitung von Messing | Oberflächen, zu berücksichtigende Faktoren und mehr

Erforschen Sie die Messingbearbeitung: seine CNC-Eigenschaften, Messingsorten, Oberflächen, Schlüsselindustrien, Top-Tipps und 5 wichtige Überlegungen.

Schulterfräsen: Präzises Zielen bei der Bearbeitung bestimmter Werkstückbereiche

Shoulder milling, much like face milling, side milling, and groove milling, is a pivotal technique in the milling process. It targets specific positions on a workpiece, ensuring detailed and precise machining. As one of the essential methods in the milling repertoire, shoulder milling stands out for its accuracy and efficiency in shaping materials. Turning Method […]

POM CNC-Bohren: Poröses Bearbeitungsverfahren

POM plastic, renowned for its suitability in injection molding, also shines brightly in the realm of CNC machining. The adaptability of POM to CNC drilling processes ensures precision-crafted components, showcasing the material’s versatility and the advanced capabilities of CNC technology.

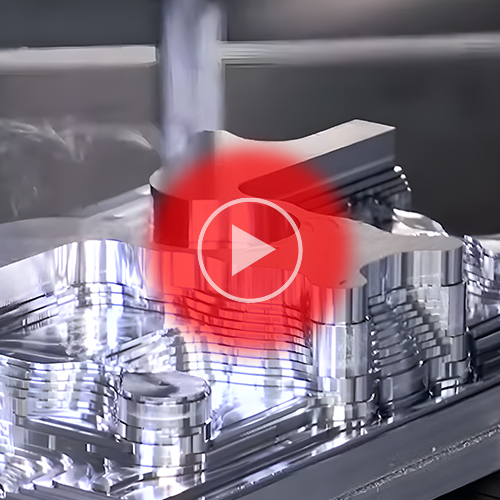

Komplexe Bearbeitungen und Fräsen unregelmäßiger Teile

The pursuit of machining intricate and irregular parts has always been a challenge in the manufacturing industry. With the advent of advanced milling machines, complex machining services have revolutionized the way we produce these detailed components. These services not only ensure precision but also enhance the efficiency of producing such intricate designs.

Bearbeitung von Zylindern mit einer Drehmaschine

Cylinder machining is a prevalent technique in the industrial sector. Typically, turning processes are best suited for shaping such cylindrical forms. There are various types of cylinders, each with a broad range of applications. From simple tasks to complex operations, the versatility of cylinder machining using turning machines cannot be overstated.

Grundlagen der Bearbeitung: die Beziehung und Berechnungsformeln von Vorschub, Schnitttiefe und Schnittgeschwindigkeit

Welche Beziehungen bestehen zwischen Vorschub, Schnitttiefe und Schnittgeschwindigkeit bei der Bearbeitung? Wie kann man sie berechnen?

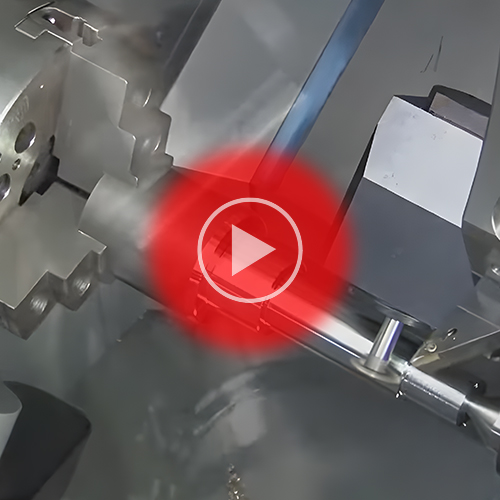

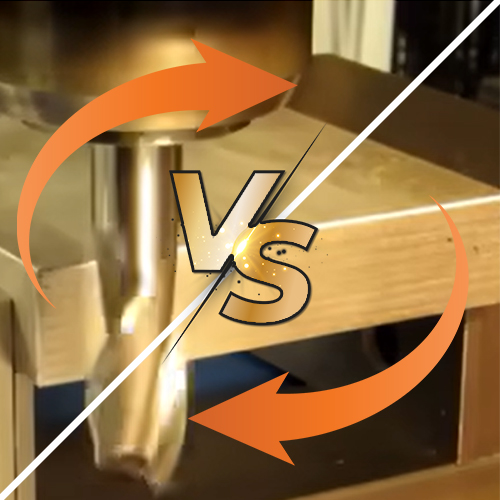

Korrekte Bedienung von konventionellem Fräsen und Steigfräsen

Explore conventional milling vs. climb milling. Find their applications and benefits. Rely on our CNC milling expertise for optimal results.