CNCプロジェクトの微調整:仕上げ加工ガイド

Surface finish or finish machining, a critical aspect of machining, delves into the fine details of perfecting a workpiece’s external quality and functionality. This precise process involves a meticulous surface adjustment, either by material removal or addition, to meet the highest standards of appearance and performance. If you’re already acquainted with the fundamentals of finishing machining, you’ll appreciate the importance of every detail. In this article, we’ll delve deeper into precision finishing machining, unraveling the nuances of this high-precision endeavor. We’ll explore the key considerations, benefits, functions, and pitfalls to avoid when striving for that exact and refined outcome. Whether you’re an industry professional or a budding enthusiast in precision […]

機械加工における中仕上げによる生産の最適化

The manufacturing industry highly values the role of semi-finishing. This crucial process involves refining a product to a specific level of completion before reaching the final finishing stage. It is pivotal in ensuring the end product meets the required specifications and standards, enhancing quality and aesthetics. Various industries, from automotive parts to aerospace components and medical devices, widely use semi-finishing. In this article, we will take a look at the intricacies of semi-finishing, its methods, and its pivotal role in delivering top-notch manufacturing outcomes. Join us in uncovering the essential aspects of this intermediate machining stage and its importance in the production process. Understanding the Mechanics of Semi-Finishing in Intermediate […]

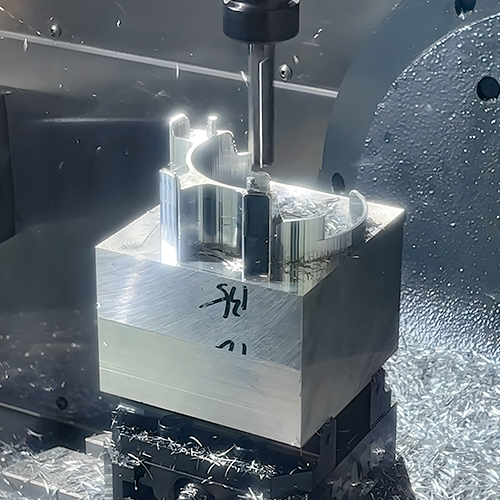

未加工から洗練へ:粗加工の方法を探る

Rough machining is a process that involves swiftly and efficiently eliminating excess material to bring your workpiece one step closer to its final design. This CNC machining approach employs larger cutting tools, making broad and powerful cuts to eliminate any unwanted material from a workpiece quickly. The result may be a coarser surface finish, but the goal is efficiency and speed. However, it’s much more than its name suggests; it’s the robust bridge between the raw material and the meticulous precision required in subsequent machining phases. In this article, we’ll talk about the important things to think about, the advantages, what rough machining does, and the usual errors people make […]

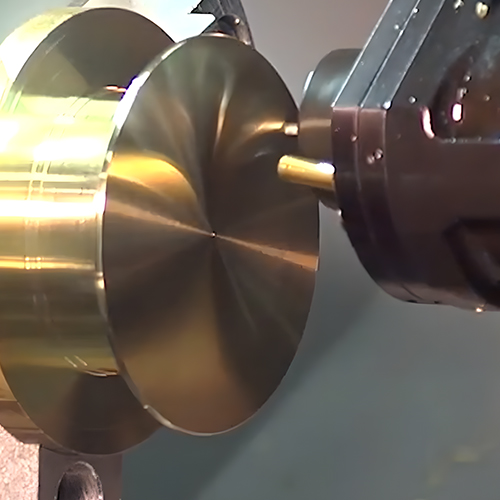

真鍮加工の包括的なCNCガイド|仕上げ、考慮すべき要因、その他

CNCの特性、黄銅の等級、仕上げ、主要産業、トップ・ヒント、5つの重要な考慮事項など、黄銅の加工についてご紹介します。

Shoulder Milling: Precision Targeting in Machining Specific Workpiece Areas

Shoulder milling, much like face milling, side milling, and groove milling, is a pivotal technique in the milling process. It targets specific positions on a workpiece, ensuring detailed and precise machining. As one of the essential methods in the milling repertoire, shoulder milling stands out for its accuracy and efficiency in shaping materials. Turning Method Milling Method Internal Turning & External TurningTaper Turning Shoulder MillingSide MillingFace MillingRamp MillingPlunge MillingPeripheral MillingHelical MillingGroove MillingVertical Milling & Horizontal MillingConventional Milling & Climb Milling

POM CNCドリル加工:多孔質加工プロセス

POM plastic, renowned for its suitability in injection molding, also shines brightly in the realm of CNC machining. The adaptability of POM to CNC drilling processes ensures precision-crafted components, showcasing the material’s versatility and the advanced capabilities of CNC technology.

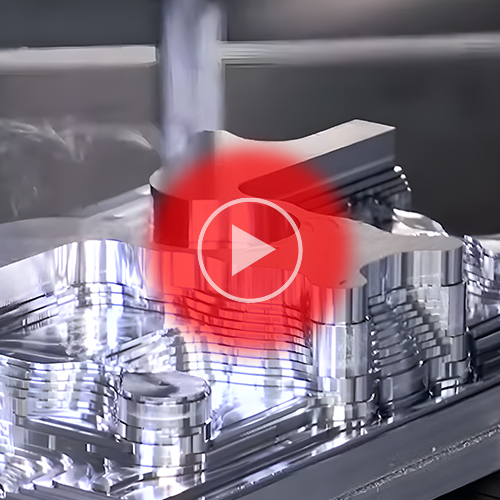

複合加工サービス & 不定形部品フライス加工

The pursuit of machining intricate and irregular parts has always been a challenge in the manufacturing industry. With the advent of advanced milling machines, complex machining services have revolutionized the way we produce these detailed components. These services not only ensure precision but also enhance the efficiency of producing such intricate designs.

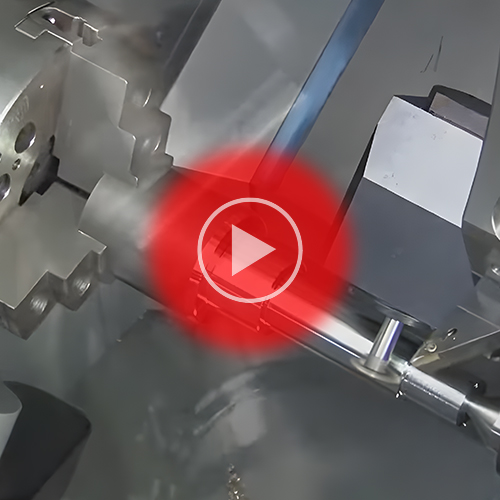

旋盤によるシリンダー加工

Cylinder machining is a prevalent technique in the industrial sector. Typically, turning processes are best suited for shaping such cylindrical forms. There are various types of cylinders, each with a broad range of applications. From simple tasks to complex operations, the versatility of cylinder machining using turning machines cannot be overstated.

Machining Essentials: the Relationship and Calculation Formulas of Feed Rate, Depth of Cut & Cutting Speed

What are the relationships between feed rate, depth of cut, and cutting speed in machining? How to calculate them?

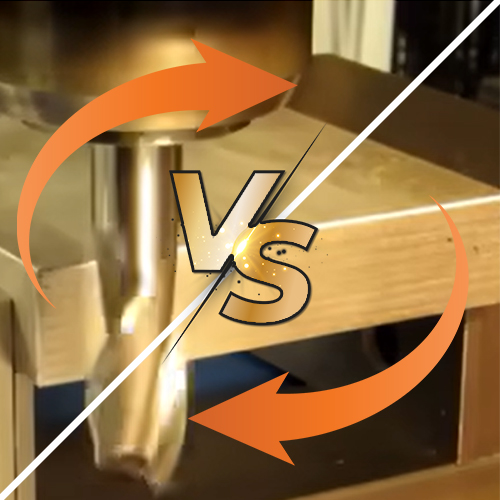

Correct Operation of Conventional Milling and Climb Milling

Explore conventional milling vs. climb milling. Find their applications and benefits. Rely on our CNC milling expertise for optimal results.