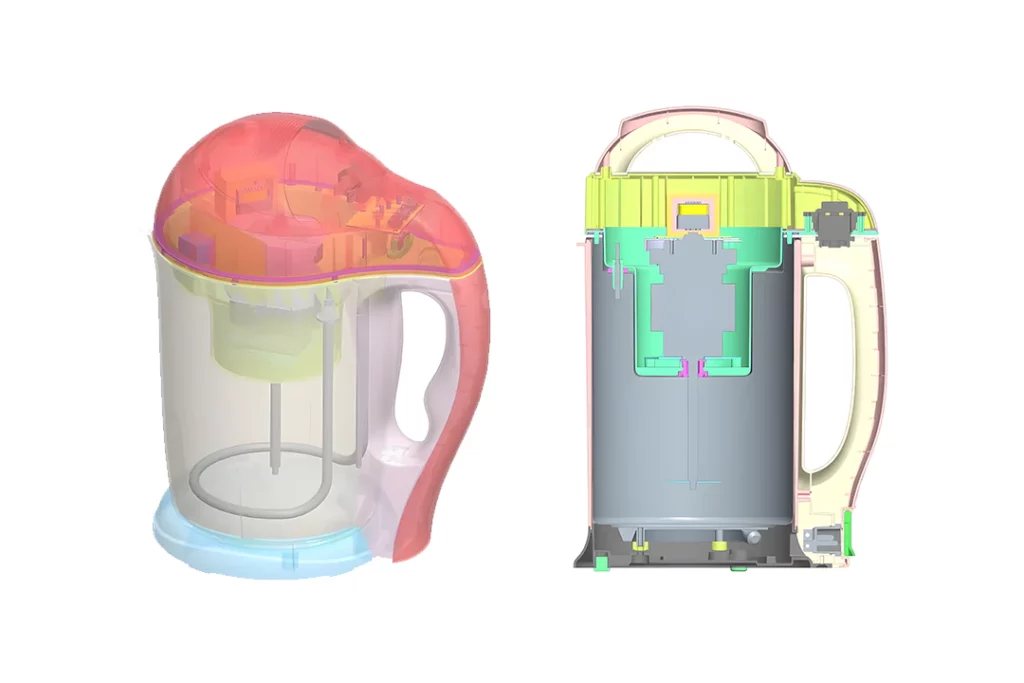

In this exploration of soymilk maker housing mold design, we delve into the case study of a soymilk maker’s head unit, analyzing the intricacies of injection molding design for home appliance products.

Material Selection for Durability and Aesthetics

In soymilk maker housing mold design, the choice of materials is crucial. In general, in the material selection process, soymilk maker housings primarily utilize PP (Polypropylene) and ABS (Acrylonitrile Butadiene Styrene). ABS boasts excellent flowability, low shrinkage, strong heat resistance, and impact resistance, making it a popular choice. Products made from ABS exhibit a high-quality surface gloss and wear resistance. On the other hand, PP material, while having good injection molding properties, tends to have a high shrinkage rate, leading to potential deviations in product precision and deformation. Additionally, PP can suffer from issues like poor gloss and shrinkage marks, though it is more cost-effective than ABS. Considering the need for high gloss and temperature resistance in soymilk maker housings, ABS is the preferred material choice.

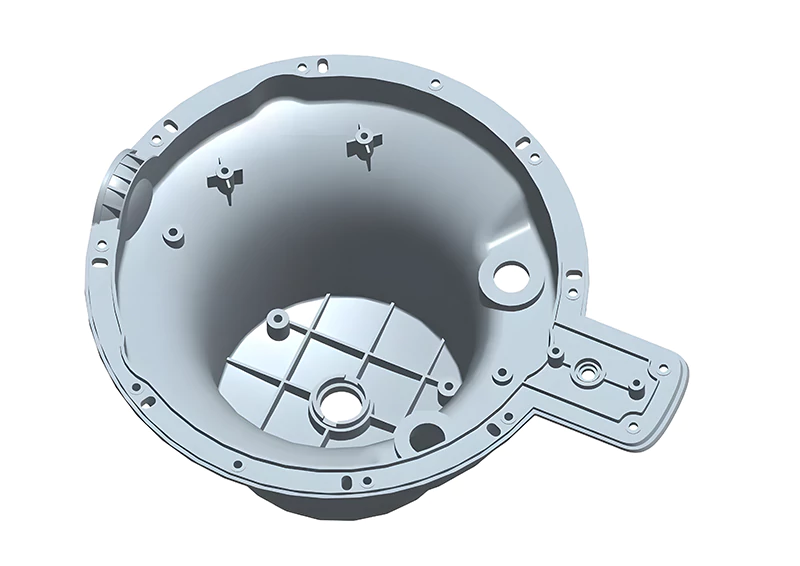

Designing Screw Columns and Reinforcement Ribs

For assembly purposes, the soymilk maker’s head unit housing requires several screw columns. The design includes volcano treatment at the base to prevent shrinkage marks. Reinforcing ribs enhance the strength of each screw column. It’s essential to control their thickness carefully and include adequate R angles to improve the solvent’s flow. In the design of the gating system, the housing must be smooth, with minimal residual marks post-demolding. This necessitates the use of point gating to allow the gate to detach naturally. Designers must develop a balanced runner system from direct to point gating, utilizing a circular manufacturing process to reduce runner volume, save injection time, and enhance production efficiency.

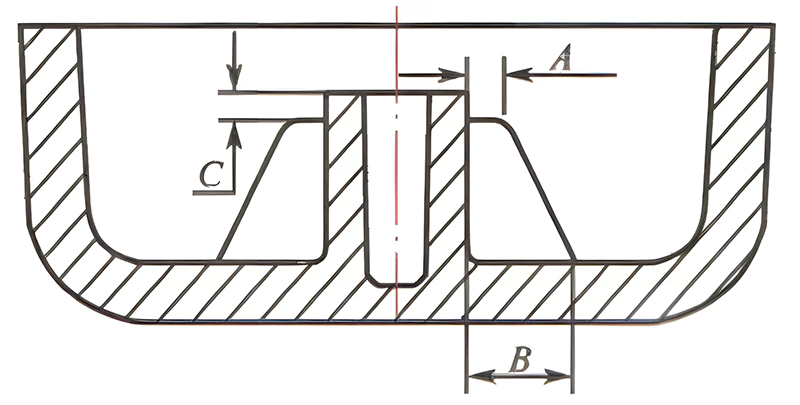

Molding Process and Precision

In this soymilk maker design, the head unit’s housing is secured using a snap-fit concave groove. The mold design incorporates lateral parting core pulling and inclined top structures. Two factors influence the dimensional accuracy: the variability of the plastic’s shrinkage rate and mold processing errors. For surface quality control, the housing requires flawless internal and external surfaces, with smooth edges free from weld lines or spots. The internal surface roughness standard is Ra0.4μm, and the external surface is Ra0.2μm. Surface gloss issues are often due to premature cooling of the melt, insufficient drying time, inadequate mold temperature, or substandard polishing.

Addressing Injection Molding Defects

Shrinkage Issues

Shrinkage in injection-molded housings is often related to the internal structure and excessive thickness of ribs. This can cause abnormal solidification during cooling, leading to surface depressions. To mitigate this, the injection molding process must be optimized with scientific shrinkage prevention measures. You should control the thickness of the ribs within reasonable limits, utilizing the lower shrinkage rate of ABS material. For PP, with its higher shrinkage rate, the rib thickness should generally be one-third of the main rib thickness. A combination of internal and external structural considerations is necessary to prevent shrinkage in the housing.

Short Shots

This issue arises from overly thick mold design structures, poor venting, or uneven wall thickness. To address this, you should scientifically set the injection pressure, gradually increasing it until achieving the desired fill. If issues persist, the injection mold may need to be adjusted, including changing the gate position and conducting feasibility tests until successful molding is achieved.

Weld Lines

Weld lines on the surface of home appliance housings are often due to the addition of aggregates beyond normal processing requirements, leading to hidden marks or cracks under external forces. Increasing mold temperature and injection pressure can resolve this. If problems persist, enlarging the gate size may be necessary.