Injection mold — the principal tool that handles the injection molding process, where you inject plastic material into this mold tool. Once it cools and hardens to the cavity configuration, you get a plastic injection molded product. Today, injection molding technology is best employed to mass-produce highly accurate and frequently complicated end-use parts.

3D printing often creates prototype parts to detect form, fit, and function concerns. However, because 3D material qualities differ from those utilized in injection molding, 3D printed prototypes cannot provide a thorough assessment of an injection molded part‘s functional performance. Until recently, manufacturers could only design and functionally test injection molded parts by making an aluminum (soft) tool. While this injection mold is significantly less expensive than its steel (hard) counterparts, the expenses and lead times remain significant.

But do cost efficiency, faster production, and usage convenience also come with smooth mold delivery? Or do factories frequently face mold delivery time issues when producing this injection mold for your personalized product manufacturing needs? With different products that injection molding manufactures, you need a personalized mold with a shape, size, and other qualities. This mold help make product manufacturing more accurate and efficient. Let’s explore how injection mold manufacturing and delivery may face delays depending on the mold company you choose.

Delivery Time Given by Mold Factory: What It Is and Why It Delays?

Typically, when you give an order for a large-batch mold production to a mold manufacturing company like Prototool, the company gives you an estimated delivery time. However, it often needs to be more beneficial to consider the delivery time and expect a strict delivery. That’s because most factories encounter delays and defaults in delivery. These delays happen when the process of understanding the mold criteria, performing the production, ensuring quality and testing, finalizing the injection mold, packing, and delivery takes different timing. These timings vary from company to company. It also depends on how they handle each task or if they face any errors or issues during these phases.

Various factors can contribute to the delay of a project, whether it’s for the production of plastics or elastomers. Problems with deliveries made at any point in the supply chain are frequently to blame. Especially at the beginning of a project, there is a time factor that only a few clients keep in mind. However, it accounts for a non-negligible part of the lead time before the start of series production. That time factor is the fabrication of the tooling or mold for the product. It may not seem so at first glance, but this issue’s complexity extends to rubber and plastic goods. During the project’s development phase, the project’s completion on schedule is only possible if customers underestimate the manufacturing of the tool.

Factors Affecting Delivery Time:

Various factors that affect the delivery time of a mold for companies include:

Tool Geometry:

The molding tool’s geometry must precisely match the dimensions of the molded parts that will be produced, including any required tolerances. Because of this, you need to fabricate a unique tool for every project following a specific customer drawing. This process involves not only mold design but also manufacturing and transportation. Tooling is classified as a project within a project. The manufacturing chain’s most crucial component when producing a part that functions. Unsurprisingly, the sheer volume of work involved frequently prolongs the time it takes to complete the manufacturing process.

There are four influential primary variables. These variables, at most, cause a delay in the timely delivery of the mold. They also delay the beginning of manufacturing of the molded part:

- The construction in question.

- The production process

- The transportation of the tool

- The release of it.

Size Issues:

Another prominent issue that causes a delay in injection mold production and delivery is improper size production. So, the manufacturer needs to learn the setup of production tools and machines correctly. Otherwise, the size of the mold won’t match the size of the product, making the mold faulty. Besides, the size of the product is one of the most substantial aspects. This aspect impacts the performance and outlook of the finished result.

With improperly sized production of an injection mold, the company has to go through every mold manually. Companies then analyze the size to ensure which mold meets the size requirements. In large batch production, this may take a lot of time. Moreover, once they exclude the improper-sized molds from the produced batch, they need to produce new molds of the same amount. Only then can the company meet the quantity demands of the order. This entire process can be a significant cause of delay in mold delivery time.

Material Availability and Transportation:

Another important consideration is the logistics. If an external partner manufactures the mold, there is a possibility that transport will cause delays, depending on the circumstances. Again, this depends on whether the mold manufacturer works with a local or an international mold maker.

If the mold is manufactured in Germany or a neighboring nation that is a member of the EU, shipping takes less time. Moreover, the factory can handle it in-house. Nevertheless, there is always the possibility of experiencing delays due to the weather or the traffic. If the toolmaker has production facilities in Asia, the circumstances are different. If this is the case, transportation can take a very long period. The transport of the tool via air freight is a relatively speedy option; however, this option is only sometimes available. Many businesses decide to convert to less expensive modes of transportation when there is much cost pressure. It can include sea freight or rail transport. The length of time required to deliver the goods increases correspondingly.

Understanding Product Design Requirements:

Before contacting a production company like Prototool, customers must produce a design drawing of the needed molded part as a standard operating procedure. On the other hand, the geometric requirements of the finished component are typically the emphasis of this design rather than the component’s fabrication. Consequently, customer specifications are rarely determined by manufacturing requirements.

The absence of draft angles or radii is a problem that frequently occurs. Other types of mistakes include production-specific mistakes and those made by designers unfamiliar with the subject matter.

One illustration of this is how rubber and plastic both behave differently when it comes to flow. The liquid latex is added to the mold while it is still hot, and once it has reached the desired consistency, it is allowed to cool and harden. On the other hand, rubber is set inside a mold while it is still cold and then either heated or vulcanized after it has been poured into the mold. During the process of making either of these products, the raw chemical undergoes a series of transformations that cause it to behave in quite different ways. The nuances, on the other hand, can be found in the materials employed.

During the injection process, the flow of any substance, whether it be plastic or rubber, is distinctively different. When selecting the kind and method of gating, experience is necessary because, in its absence, a variety of flaws might manifest in the material of the final product, such as obvious flow problems.

First, the manufacturer should make sure to meet all of the parameters, and then they will construct a realistic mold concept for further coordination with the client. This process will ensure that no design faults will affect the production of the molded parts. Hence, this process does take some time. At this point, you need to be very careful because you need to get rid of this extra loop as soon as possible, even if there are mold changes you need to cater to later.

Tolerance of Production Tool: High precision Instruments are used to manufacture molded parts. Even slight departures from the design parameters, particularly in conjunction with close tolerances, can render the products that have been manufactured useless. Because of this, the tool undergoes a comprehensive inspection before the production process begins.

This activity involves participation from several different parties. First, the toolmaker ensures that he has correctly executed all standards by inspecting his work. After that, the manufacturer of the rubber will re-measure specific measurements one last time before inserting the mold in the production line and configuring it to work with the injection molding machine. The person who will ultimately buy the molded part has no direct involvement in this procedure. Nonetheless, he verifies the correctness of the mold in a roundabout way by analyzing the samples generated using it and checking the first sample report.

Taking precise measurements is time-consuming, mainly because of the need for accuracy. Professionals usually use specialized devices for this purpose; these tools can detect even minor errors.

The Difference in Delivery Time: How is Rapid Tooling and Conventional Tooling Different?

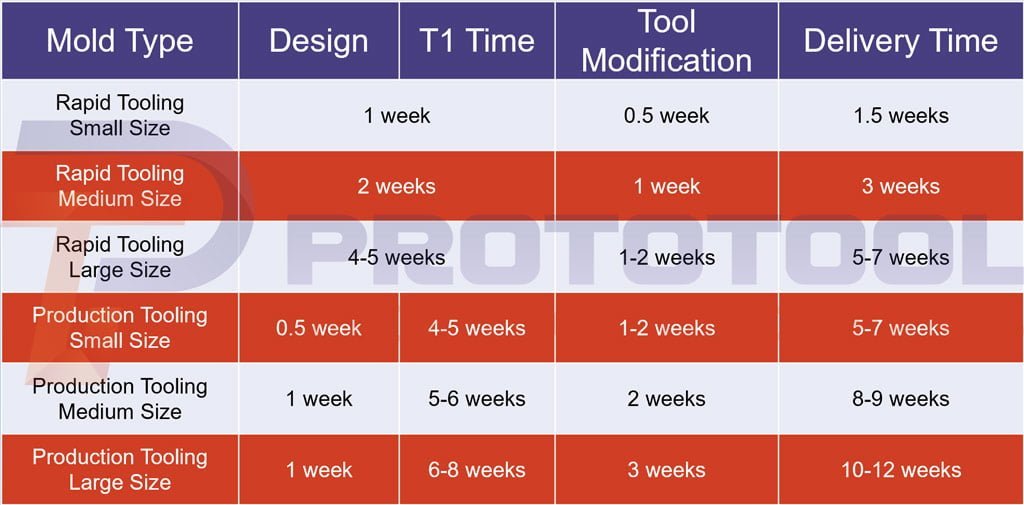

The product’s delivery time also changes depending on the production process you choose for manufacturing injection mold for your product. Hence, the company’s ability to deliver the large-batch injection mold to you can also differ with different production processes. What massively affects this delivery time is the preference of the production company for choosing and finalizing the production method according to your product demands. Additionally, various other factors differentiating the rapid tooling and conventional tooling production methods further increase or decrease the delivery time. Let’s explore these aspects below in detail.

Choosing the Appropriate Tooling Method: Important Considerations

The following are some fundamental factors that product designers and engineers consider when selecting a tooling method and completing it with you under your production requirements.

Design Stage

There is always room for development in every product’s design. The critical question is how far the designer will go to get to a point where it is production-ready. They will use the response to determine whether they need additional time for prototyping or whether they can start production after receiving the answer. The level of difficulty inherent in the product. When a product has more complicated components, it will take longer for the company to create a prototype and finish the process before it can go into production.

Intended Market

You should pay attention to who will use the product when selecting the tooling method. According to the target market, each will have specific requirements for the necessary tools.

Competition

When you have your target audience, there is a good chance that you will face competition from other businesses operating in the same market. Even though this is the first time anyone has ever thought of this, it is common for multiple people to devise the same solution to a common issue simultaneously. Whoever is successful in bringing their product to consumers first will emerge victorious.

Budget:

When developing a prototype, the kind of tooling that you will employ will depend on the available budget. Most designers will save money by commencing their projects with less expensive tooling options.

By keeping these essential considerations in mind, product designers can better assess their requirements when deciding between conventional and quick tooling.

The Key Distinctions Between Traditional Tooling and Modern Rapid Tooling

It all comes down to the various production techniques utilized to manufacture a product, although conventional tooling can cover a broader range of applications. Such processes require automation and require human participation at various points. Rapid tooling, on the other hand, is linked with rapid prototyping and is put to use in developing product models and resolving existing problems. It is only put into action in production runs involving many items. Direct and indirect tooling are both included in the category of rapid tooling.

The following comparison of quick tooling and conventional tooling that affects the injection mold delivery time is based on three distinguishing characteristics:

· Speed

Rapid tooling is significantly quicker than traditional tooling, which is where it gets its name. It is beneficial in time-sensitive short production runs, such as in rapid prototyping, where you have a limited time. Utilizing rapid tooling is the solution in this scenario to the problem of meeting the desire for a speedy process that enables several iterations of the same concept.

· Cost

The use of rapid tooling is more cost-effective than the use of conventional tooling because it takes less human labour and less time. It is not susceptible to human errors because computer programs and machines handle it instead of people. It results in further savings on labour and less waste than usual.

· Quality

The use of quick tooling can be problematic in terms of durability and lifespan. It also affects the longevity of the items manufactured with these different tooling. On the other hand, this is partially problematic because some products do not require a longer shelf life. As a result, there is no requirement to invest in its tooling.

Common Causes of Delay in Delivery Time:

In the entire production and manufacturing process of injection mold, many aspects are difficult to control. The delivery problem of injection mold is the most challenging point to manage. Therefore the question becomes: what causes the difficulty in delivering injection mold?

It includes the following:

- Commonly, a delay is caused when the details of the customer’s order are still being determined, and the contract and the design are subject to numerous revisions.

- A custom-made item is an injection mold. So, the time it takes to confirm a mold drawing is directly related to the time it takes to deliver an injection mold. The delivery time is delayed unless the mold drawing certification is completed promptly.

- The standard manufacturing order faces a delay in exceptional circumstances, such as when many urgent orders are inserted.

- Neither the cooperation of the provider nor the necessary materials will be available on time. In addition, it is one of the most typical causes of delivery delays.

- An unrealistic control of the injection mold project will also cause a delay in the project.

- Issues with the product’s quality during production; scrap, rework, repair, etc. It will result in wasting significant financial, human, and material resources.

All of those above are significant issues that could slow the delivery. After getting the order, a professional injection mold factory needs to perform well in project management and control to maintain its reputation. They should give it their entire study to devise an additional specific plan. During the manufacturing process, the factory must also establish plans on time. They will be able to do an excellent job in project planning this method, which will significantly improve the on-time delivery time at the injection mold factory.

Further Details to Ensure Faster Delivery and Efficient Quality of Production:

Apart from understanding the basics, an efficient way to speed up injection mold manufacturing and delivery is to hire an experienced manufacturing factory. With experience comes an understanding of how every process should be handled according to your product and mold specifications. Furthermore, having experience allows the production factory engineers and machine operators to understand better how to choose and adjust the production methods and tool performance according to mold size and other requirements.

Furthermore, when choosing faster production, there are other necessary steps than choosing a professional company. Instead, choosing a single company or factory for mold and product production adds more convenience and quality. Hence, when trusting a professional and experienced factory that knows how to produce an injection mold, it’s essential to consider choosing a factor that uses the produced molds to proceed further with the product manufacturing.

This way, you can achieve a final product in less delivery than waiting for a factory to produce the injection mold and then giving these molds to another factory to start product manufacturing. In this situation, not only is the time to find another company and move the molds added to the overall production time, but you also have to share and consult the product manufacturing requirements with the new factory. As a result, this only lengthens the entire process until you have the final product ready to be delivered/sold to the suppliers or target market.

—

This is our detailed guide on injection mold and product delivery timing. Feel free to contact us with more questions.