Introduction to Helical Milling

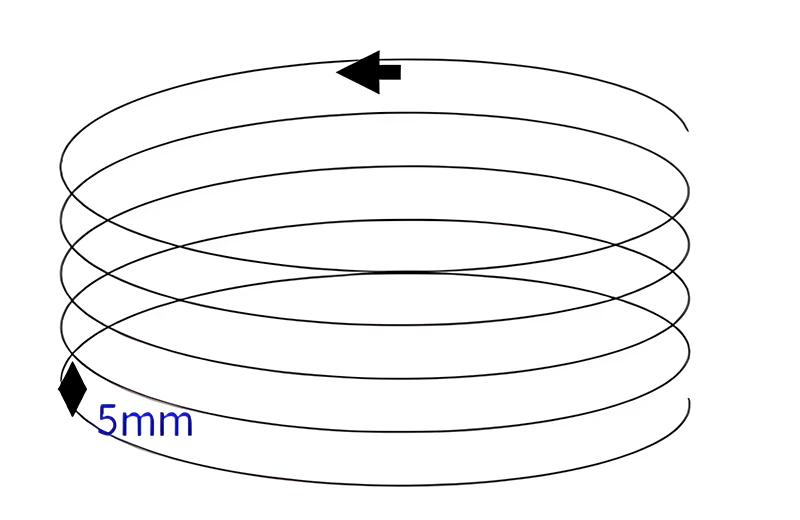

Helical milling is a machining process where the tool path resembles a spring. During this process, the cutting tool follows a programmed helical path to progressively cut the workpiece, achieving the desired dimensions. The choice of tool is crucial in helical milling. Generally, the tool diameter is selected to be 40% to 60% larger than the milling size and the helical radius of the workpiece. The size of the non-cutting center of the tool significantly affects the tool’s cutting life. The Z-axis feed, or the depth of cut, is typically around 20% of the normal cutting depth, but this can vary depending on the material and specific machining conditions. Helical milling is often used for initial drilling and hole-making, especially in softer materials. However, it’s less preferred for machining steel components due to rapid tool wear, which significantly affects tool life.

Contour Milling

Traditionally, slot milling with a keyway mill is used for machining cavities, which is less efficient. When using end mills for cavity machining, the efficiency is higher. However, direct vertical plunging with an end mill can cause significant damage to both the tool and the workpiece. To address this, CNC machining often employs helical milling or ramping down techniques. Programming the tool to spiral down along the cavity contour improves machining efficiency and extends tool life.

Hole Machining Technology Analysis

In helical milling, the spindle rotation of the machine tool is adjusted for effective engagement. The motion structure is modified according to the central rotation position for specialized machining methods. The process parameters of helical milling, such as cutting speed, are controlled to ensure stability during cutting. The cutting tool may experience significant pressure, and after machining, the workpiece’s precision is assessed to determine the tool’s central point and cutting trajectory. Adjustments are made based on the cutting path and spiral line position. The entire machining state is adjusted for controlled operations, combining actual cutting standards and tool modes. This approach saves machining time, improves process quality, reduces the rate of defects, and enhances the overall efficiency of the component.

Thread Machining

Traditional thread milling methods primarily use thread mills to cut components, ensuring precision in the machining process. With the advancement of CNC technology, three-axis coordinated machine control methods are used for thread cutting. This modern approach to thread machining offers significant advantages in terms of precision, efficiency, and cost over traditional methods. It also avoids interference from thread structure, direction, and spacing between adjacent threads. In mechanical machining, if the thread mill is directly used to create various rotational structures, traditional turning methods can be employed for complex structures. However, CNC cutting offers greater precision and allows for effective adjustment of thread diameter sizes, significantly improving the accuracy and efficiency of the machining process.