Are you struggling to understand what a tool turret is? Simply put, indexing tool carriers for tornos, transfer machines, and other CNC machine tools are known as tool turrets. They enable equipment to carry numerous cutting tools simultaneously and mount individual tools properly.

These tool turrets can replace a manual tool post or rotary indexer, increasing processing efficiency and lowering setup costs.

Understanding the working and performance of a tool turret helps operate a CNC machine for part production more efficiently. In this article, we will study what a tool turret is, how it functions, and what can happen if it is not maintained during Maquinação CNC processos.

Sugerido: 6 Desafios comuns enfrentados pelas empresas de fabrico CNC

CNC Tool Turret Overview:

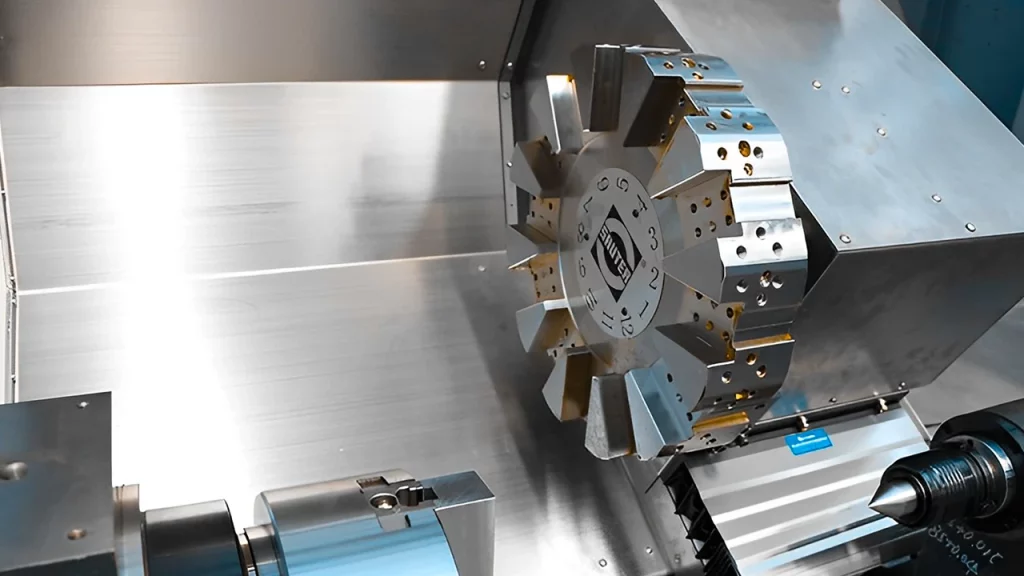

In a computer numerically controlled (CNC) machine, a turret is a tool-changing device that allows rapid and effective switching between various cutting tools. Furthermore, this component helps increase the effectiveness of the machining process, which is an essential element of the CNC machine.

The turret is often attached to the spindle of the CNC machine, where it functions as a holder for various cutting tools and can rotate 360 degrees. You can turn the turrets to move your desired cutting tool into the appropriate position.

Because it enables tools changes to occur promptly and organized, the turret is an essential component of the CNC machine. This is significant because it eliminates the need for the operator to manually replace the cutting tools on the machine, enabling it to transition rapidly between various cutting tools. This results in an improvement in the effectiveness of the machining process and a reduction in the amount of time necessary to do a task.

Functionality and Components

The turret is usually constructed out of several different parts. The turret is the initial component, a revolving mechanism holding the cutting tools. The tool holder is the second component, and its purpose is to keep the cutting tools from moving around while they are being used.

The tools changer is the third part of the machine, and its purpose is to rotate the turret and put the necessary cutting tools in the appropriate location.

A computer numerical control, or CNC, is usually used to run the turret. Controlling the movement of the turret and the tool changer is accomplished with the help of this system.

The computer numerical control (CNC) system is pre-programmed with the cutting tool and turret position that the user wants. After that, the CNC system will send signals to the turret and the tool changer, which will cause the turret to move and will bring the appropriate cutting tool into position.

How Does The Absence of a Tool Turret Affect CNC Machining Processes?

A tool turret is a significant component in a CNC machine. This component serves as an efficient tool-changing device.

Having said that, if a CNC machine does not have a tool turret, it may experience several problems that slow the machining process and harm productivity. The following are some common issues that may manifest themselves:

● Manual Tool Changes:

In the absence of tool turrets, it will be essential to perform manual tool changes. This can be a time-consuming process and increase the amount of setup time required between machining operations.

Manual tool changes also bring a more significant chance of errors. These errors can include poor tool tightening or misalignment, which can impact the precision and quality of the machining process and part production.

● Extended Downtime:

Changing tools manually or with broken tool turrets may result in increased downtime for the machine. The time needed to switch tools and adequately align them may drastically affect productivity.

This becomes an even more critical consideration when the machining procedures entail frequent tool changes or complex operations that call for several tools.

● Reduced Efficiency:

A CNC machine that does not have a tool turret or a tool turret that is not performing properly will often have reduced efficiency. The machining process is slowed since it does not use automated tool changes and indexing capabilities.

Because switching between tools takes manual intervention, this results in increased idle time, decreased throughput, and lower overall productivity.

● Restricted Machining Freedom:

A CNC machine’s machining freedom is restricted because it lacks a tool turret. When doing sophisticated processes that entail extensive tool paths or require many tools, you will find that it becomes increasingly difficult.

The machine’s inability to efficiently complete various machining operations is restricted since it does not have tool turrets. As a result, the types of projects that can be completed may be restricted.

● Inconsistent Machining Results:

A defective tool turret could cause inconsistent machining results. A misalignment of the tools or an insufficient força de aperto might result in variations in the dimensions of the item, as well as poor surface finishes and an overall reduction in its quality. Machining operations can lose their precision and repeatability if the tool is incorrectly positioned.

● Increased Probability of Operator Errors:

There is a greater possibility of operator errors when manually changing tools because the tool turret either does not exist or is not functioning correctly. This includes mistakes in the tool’s selection, the tool’s alignment, and the tool’s tightening. Incorrect actions taken by operators can lead to wasted materials, additional machine downtime, and rework.

● Safety Concerns:

Equipment operators may be exposed to dangers if the tool turret is broken. During the machining process, tool breakage can occur if the tools are not correctly fastened or aligned, resulting in tool pieces flying around and perhaps inflicting injury. Furthermore, accidents will likely occur during the manual tool-changing process if no automatic tool-changing devices are present.

Relacionadas: Passos a considerar no processamento de projectos de maquinagem CNC

Functions of a Tool Turret:

The tool turrets in a CNC machine serves multiple essential functions for efficient machining operations. Here is a detailed explanation of the functions performed by a tool turret:

Tool Turrets’ principal role is to securely retain and position a range of cutting instruments. It is made up of several tool holders that are placed in a revolving disk, drum, or revolver-like form. These tool holders handle specialized cutting tools such as drills, end mills, taps, and inserts. The tool turret keeps each tool securely in place throughout the machining process.

Choosing a Tool

The tool turret enables quick and automatic cutting tool selection. The CNC program identifies which tool is needed for a particular operation, and the turrets rotate to place the selected tool in the machining location. This eliminates the need for manual tool changes and shortens setup time, allowing for smooth transitions between tools and activities.

Tool Changing

During machining, the tool turrets allow quick tool changes. When a different tool is required, the turret indexes to position the chosen tool. The CNC software controls the tool-changing mechanism, which releases the current tool and securely clamps the new tool in place. This automatic tool-changing capacity reduces downtime and increases machining efficiency overall.

Tool Positioning and Alignment

The turret guarantees that each tool is precisely positioned and aligned. Tool positioning precision is critical for attaining the required machining results, preserving dimensional accuracy, and minimizing mistakes. The turret’s indexing system and power transmission systems work together to precisely spin and position the tool holders, enabling consistent and repeatable machining processes.

Tool Management

The tool turrets aid in appropriately managing tools in CNC machining. It offers a central spot for storing and organizing various tools, making them easier to access and administer. Furthermore, specific advanced CNC machines and tool turrets have tool presetting and monitoring systems, allowing quick setup and real-time tool wear or breakage monitoring.

Increased Machining Flexibility

CNC machines gain flexibility by having a turret. The machine’s capacity to switch between tools and complete numerous operations without operator intervention allows it to handle more machining tasks. This adaptability is especially useful for complex machining procedures requiring many tools and operations on a single workpiece.

Conclusão:

A tool turret streamlines the machining process by enabling automated tool changes, reducing setup time, and providing the necessary precision and flexibility to accomplish a wide range of machining operations. The tool turret maximizes productivity, improves machining efficiency, and achieves accurate and consistent results.

All in all, understanding the usage and monitoring of a turret’s performance is crucial to maintaining an effective CNC machining process. Therefore, professional technicians in CNC machining service-providing companies like Prototool ensure proper maintenance and usage of a tool turret.

Sugerido: Fresadora CNC vs. Router - Comparação de velocidade, função, precisão, custo e muito mais!

FAQ:

What is a Tool Turret?

The turrets are rotatable disk-like tool posts capable of holding many tools. Instead of changing tools for numerous procedures, you can load them all into the turret simultaneously. So, whichever tool is required, the turret turns and selects that tool, known as ‘Indexing.’

Does a Tool Turret Make CNC Machining More Efficient?

The turret is an essential component of the CNC machine because it enables quick and efficient tool changes. This improves the efficiency of the machining process and shortens the time required to accomplish a project.

A CNC machine controls the turret, typically comprising numerous components. The CNC machine is configured with the intended cutting tool and turret location, which then sends signals to the turret and tool changer to move the turret and position the necessary cutting tool.