Plastic injection molding is a standard manufacturing process used in the industrial sector today. However, plastic products produced using this method are utilized in different industrial sectors and as a wide array of products. Hence, the types of plastic products produced during plastic injection molding are endless. Likewise, when it comes to the types of plastic injection molds, there is a wide range of molds for plastic injection molding used in this process for the production of different products, as per consumer demands.

But how do you evaluate what plastic injection molds are ideal for producing products that you demand? While each type of mold is ideal for meeting different production demands, it’s crucial to know how these types of molds are structured and how they serve in the plastic injection molding process. In this way, evaluating which mold should be used when injecting the plastic can be easier.

For a more precise idea and a better understanding of the types of molds for plastic injection molding and design, let’s explore each of them below in detail.

The Types of Molds:

Depending on the plastic parts’ structure and design, the molds’ usage can differ. It is mainly because each plastic injection mold helps create a product in different structures, shapes, designs, and quantities.

Some of the common types of plastic injection molds used in various companies include:

Low / High Cavitation

The Design

Single cavity e multi-cavity moulds are the most common type of mold used for injection molding. These molds represent a low/high cavitation process in the plastic injection molding production method.

Here, the single-cavity injection mold comprises only one cavity. This structure allows the cavity to produce only one plastic part simultaneously during a single injection cycle. In contrast, multi-cavity molds for plastic injection are designed with more than one cavity. As a result, this mold produces more than one plastic part during a single injection cycle.

Advantages and Disadvantages

Where the production of a single product only during one cycle using a single cavity mold works as a disadvantage, it also brings along the advantage of cost-efficiency linked with this type of mold. In simpler terms, with a low cavitation/single cavity mold, the part volume is generally low, making the plastic parts cheaper to build using such molds.

However, another disadvantage of using the single cavity mold is the higher cost of the produced parts in molding production due to the limited part production.

In contrast, the double cavity molds for plastic injection molding and design comprise the benefit of multiple productions in a single cycle. While more parts of the same design and structure can be built using such molds, the increased production capacity also brings along lower piece part costs – allowing more products to be manufactured in a decent cycle time.

The only drawback here is the high initial investment cost for a multi-cavity mold used in plastic injection molding. Yet, once you bare this higher mold cost, you can later expect it to be compensated with the lower unit part molding costs it will produce.

Aplicações

As evident as it is according to the conceção do molde and advantages of the single and multi-cavity molds for plastic injection, the application of a single cavity mold or low cavitation mold is a company or business that requires a small production volume of plastic parts.

However, applying the double cavity or high cavitation mold can be the companies or businesses that demand a large production volume of plastic parts in a specific timeframe.

Family Mold

The Design

A bolor familiar for the plastic injection process comprises a single mold base with two or more different types/designs of cavities. Hence, where a multi-cavity mold produces more parts in a single cycle, a family mold is ideal for producing multiple parts in design or structure.

This type of mold for plastic injection is used to produce different types of plastic parts in a single cycle; it can produce plastic parts simultaneously or through shut-offs. These shut-offs help isolate the production process to a specific cavity so that multiple parts of the same type are produced with the help of the selected cavity.

Using these types of molds for plastic injection molding and design, even when they produce different parts, it is best to keep the size, shape, resin, and volume of the parts similar when using each of the cavities. This is especially important if all the parts are to be produced simultaneously using the family plastic injection molds.

Advantages and Disadvantages

The usage of a family mold offers a vast number of advantages and disadvantages. One of the significant benefits of such plastic injection molds is the limited cost of production and versatility, especially if the production volume is low. In addition, these molds also offer fast molding cycles and practical usage convenience for prototype molds.

In contrast, the disadvantages of using a family mold include the increased risks of molding defects and the difficulty of changing the order or material for different cavities according to usage. Moreover, another loophole that comes along with this mold type is the unbalanced filling in each cavity, especially if the plastic parts that are to be produced are of different large shapes.

Aplicações

The family mold for plastic injection is ideal when you need to produce multiple types of plastic parts on a limited budget – all in a single production cycle.

Unscrewing Molds

The Design

The unscrewing molds for plastic injection molding are preferably used for the fabrico de grandes volumes of threaded plastic parts. Hence, threaded holes are created within the manufactured plastic parts.

Advantages and Disadvantages

The benefits of using unscrewing molds include reduced flow rate issues, limited waste, faster cycle times, limited tooling coste cleaner finishing of the plastic parts. In addition, this type of mold is also ideal for molding any kind of material.

Besides benefits, one of the most common disadvantages of unscrewing molds is the low production efficiency. The thread length of a product can cause this reduced efficiency.

Aplicações

These molds are often referred to as specialized presses and/or molds. Their application is more common for running multi-shot tooling during plastic injection molding. In addition, these plastic injection molds are typically used during high-volume production needs.

Hot Runner Molds

The Design

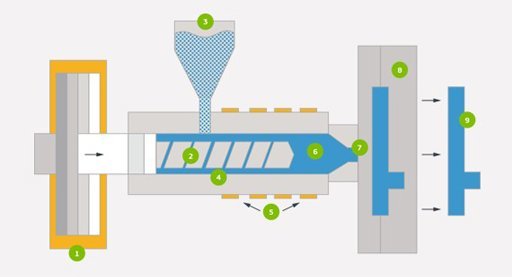

A hot runner injection mold for plastic injection is designed with two heated plates with the help of a manifold system. The two plates in these molds for plastic injection molding automotive parts or other parts are the manifold and drops.

Advantages and Disadvantages

The primary advantages of using hot runner molds for plastic injection include reduced material cost and cycle time. In addition, this mold requires less pressure to push the molten plastic forward while offering more control during the production process, adding to the quality of the parts.

The drawbacks of using hot runner injection molds include high mold and maintenance costs. This type of mold also requires frequent cleaning of the entire mold, and it isn’t preferred for usage with thermally sensitive materials.

Aplicações

The hot runner mold is an ideal plastic parts production option for large parts.

Cold Runner Molds

The Design

O cold runner molds can either be structured as a two-plate or a three-plate mold. This mold, similar to the hot runner mold, is designed with a runner system. However, the runner system of such molds does not heat.

Advantages and Disadvantages

A cold runner mold is ideal for usage if you need a simple mold design and structure and low production and maintenance costs. This mold is also easier to set up and operate than the hot runner mold.

The only loophole caused by using such moldes de injeção is the additional runner-cutting operation and the wastage of runner material if it isn’t recycled.

Aplicações

A cold runner mold designed to transfer the molten plastic inside the plastic injection mold tool helps cool down the sprue, runner, gate, and molded material.

Picking the Ideal Plastic Injection Molding Company

Depending on your production demands, it is crucial to choose a plastic injection molding service-providing company that can offer the usage of every essential mold for plastic injection, as per the product type and its production preferences.

Prototool:

Prototool is a trusted name that has served many customers for years among the wide range of plastic injection molding service providers. The company not only prioritizes the usage of all kinds of plastic injection molds, as per the production demands, but it also emphasizes every parameter involved in the production process to ensure quality and cost-efficient production of plastic parts.

In addition, Prototool offers its customers effective, time-saving, and cost-efficient prototyping, rapid tooling, and finishing services offered in every production method you can access here, including low-volume and produção em massa processes and strategies.

Does that sound like what you are looking for? Then Prototool is the perfect company for you to consider in all production needs. For further details and queries, contact us today!