Are you looking to invest in a budget-friendly, quality-focused, and reliable CNC machining company? Picking the right company for your product parts machining is a critical task. However, with endless CNC machining companies available today, which one do you choose?

Companies specialize in different areas of CNC machining tasks in the CNC machining industry. Hence, understanding your product’s machining needs and how you can pick a company that fulfills this need is crucial. In this comprehensive guide, you will find an exploration of all the factors that require consideration when making this decision.

6 Things to Consider When Choosing a CNC Machining Company:

The following are the essential considerations to bear in mind when selecting a CNC machining company to cater to your product machining requirements:

Understand Your Niche:

One of the primary factors to take into account when looking for a CNC machining company is your product specifications or project requirements. Not only should you look for a CNC machine shop with experience working in your industry, but you should also look for one that can accommodate the volume of components you need to have created.

Now checking over the potential customer’s website is a fantastic place to get started. On their website, you can view galleries of components they have created in the past and check out their qualifications, equipment, and skills. You can better understand the wide array of components they deal with and the materials they use by visiting their galleries.

After narrowing down your list of potential customers, you can contact each one individually to learn more about them. Conversation with the staff about your project is frequently the most informative and efficient approach to learning about a CNC machining company.

While conversing with the staff, you can ask about the production volumes they manage, the sectors in which they specialize, and the materials with which they work. Once you have all the information, you can decide if the firm is compatible with the requirements of your project and industry or not.

Industry Approval:

To be qualified to create parts for particular sectors, such as aerospace and medical, manufacturing shops must first clear several obstacles. Examples of such industries are aerospace and medical. Certifications that are particular to the industry are one of these obstacles. Consequently, machine shops manufacturing products for multiple industries often focus their expertise on only one or two businesses.

Likewise, certain industries, such as the automobile industry and the aftermarket for the automotive industry, do not have these ‘barriers to entry,’ which enables businesses who cater to these industries to expand into other, more niche industries such as hydraulics, weapons, and more. The production volume of the part is important, but understanding the sector your product fits into is also important.

In certain fields, certification is necessary. They demonstrate that a reputable and experienced third party has verified that the manufacturer has the necessary equipment and personnel to maintain the quality management system and that it is in place and functioning properly. Additionally, they show that the third party has confirmed that the manufacturer has the quality management system in place.

Some important certifications to look for include the following:

- AS9100– for aerospace part manufacturing

- ISO 13485– for medical products manufacturing

In addition, there are other significant certifications, such as ISO 9001, that you should consider while searching for manufacturing partners.

Customer Testimonial:

Customer satisfaction should be their top priority if a manufacturer isn’t involved in an industry like the automotive sector that requires certification.

Manufacturers often feature consumer feedback and case studies on their websites, especially if they have partnered with a large corporation or serve a broad market like the automotive industry. Customers from many industries show that the company’s CNC machining services are in high demand. In addition, a manufacturer’s credibility increases when it receives praise from well-known, significant businesses.

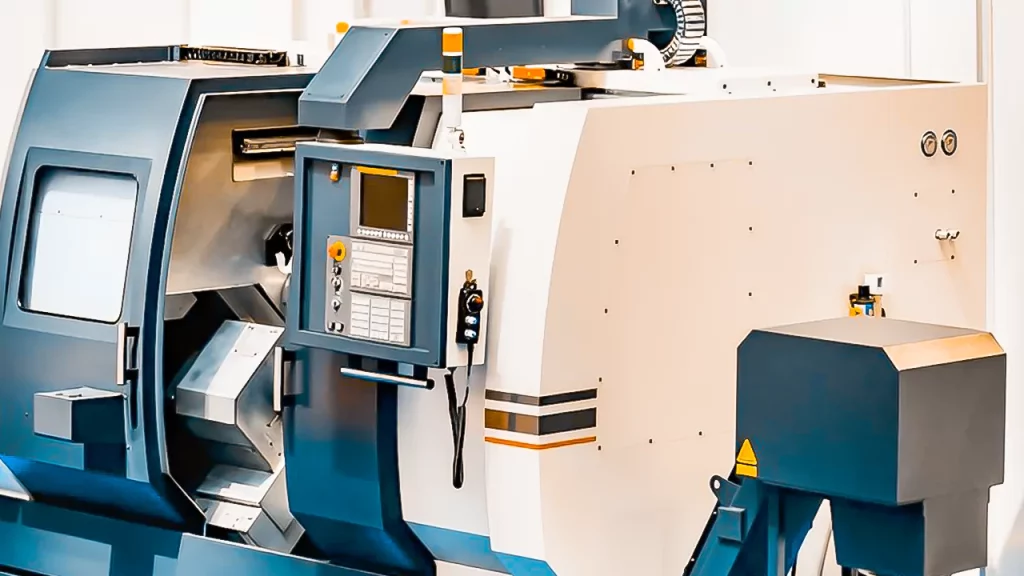

Technology and Equipment:

Another key aspect to consider when choosing a CNC machining company is to evaluate the technology and equipment of the company. By looking into the technology they use or the equipment service they provide for product machining, you can choose a company that suits your production needs. Some straightforward ways you can ensure this is by looking for:

- Updated Software: CNC machining necessitates precise programming and design, so search for a company that uses the most up-to-date CAD/CAM software to ensure accurate and efficient machining.

- CNC Machines: Search for a company with a diverse range of CNC machines, such as milling, turning, and grinding machines. The machines’ size and complexity should be adequate for your job.

- Material Handling Equipment: The CNC machining company should have adequate material handling equipment, such as cranes or forklifts, depending on the size and weight of the parts.

- Inspection Equipment: A CNC machining company should have quality control measures like coordinate measuring machines (CMMs) and other precision measurement tools.

- Specialty Equipment: If your project necessitates unique processes, such as electroplating or heat treatment, look for a CNC machining company with the relevant specialty equipment.

- Maintenance and Upkeep Tools: The CNC machining company should have a maintenance schedule to keep their equipment in good working order, ensuring it runs smoothly and effectively.

Cost and Budget:

The estimated cost and budget of a CNC machining company will ultimately depend on the specific services that the company offers and the project’s requirements. Specifically, it includes cost effecting services like:

- Labor costs

- Equipment costs

- Overhead costs

- Material costs

- Quality control costs

- Shipping and logistics cost

While you consider these basic cost-affecting factors when asking for a machining service quote from a company, look into the company’s cost categorization. The best way to choose the ideal CNC machining company is to look into their cost quotes and pick the one that is straightforward and clear with every cost involved in the service.

This way, you can be confident that there are no hidden charges that the company is charging, and you can invest in services that fit your budget.

Customer Service:

Like any other professional service or company that you invest in, looking into the customer service and response your chosen CNC machining company offers is important. By studying other customers’ and business owners’ reviews and testimonials regarding their experience with the company, you can better understand how the company deals with its customers.

Furthermore, you can also personally contact the company through their contact details shared on the Internet. This approach will help you evaluate how fast and friendly the team responds to you, allowing you to connect with them on time for any product/part issues or modifications. You can also look for reviews, testimonials, and references from the CNC manufacturer’s previous clients to understand the company’s standing in the market.

This approach will help you find a CNC machining company with a history of meeting deadlines and sticking to budgets without sacrificing quality.

Leia também: 11 produtos muito utilizados atualmente fabricados por moldagem por injeção

Advantages and Disadvantages of Investing in a CNC Machining Company:

Every production machine or service comes with its advantages and drawbacks. Hence, understanding your products or business’s manufacturing requirements and investing in the ideal CNC machining company can be challenging unless you know the benefits and drawbacks.

Some such advantages and disadvantages of working with a CNC machining company include the following:

Advantages:

Flexibilidade: Since CNC machines can be programmed to manufacture a wide variety of parts, companies that specialize in CNC machining can handle a wide range of projects. Furthermore, such companies can also adapt to the ever-changing requirements of their customers.

Speed and Efficiency: CNC machines can create parts rapidly and efficiently. Hence, a CNC machining company specializing in such services can offer quick turnaround times and meet stringent deadlines.

Flexibility in Design: If you’re planning to invest in product machining services that fulfill unique design criteria, the good is many CNC machining companies do. This flexibility is achieved through CNC machines, which allow companies to construct complicated designs and complex geometries. In contrast, producing such designs with manual machining techniques can challenge companies with outdated machines.

Accuracy and Precision: Another crucial advantage of a CNC machining company is that their machines allow extremely high levels of precision and accuracy in production. By using these precision machines, companies can satisfy the customer’s requirements.

More About Precision Molding: Moldagem por Injeção de Plástico de Alta Precisão - 5 coisas que deve saber!

- Consistency and Quality Control: Lastly, a good and reputable CNC machining company with highly automated machines helps limit human-made production errors. This task automation guarantees the components’ production quality between small and large-scale batches.

Disadvantages:

Initial Costs: Because CNC machines are expensive to buy and keep running, it can be challenging for smaller businesses or individuals to invest in this technology. Furthermore, bearing the production costs of advanced CNC machines can be difficult for a CNC machining company.

Limited Material Options: A CNC machining company often offers its customers a limited selection of available materials. It is primarily because CNC machines are best suited for cutting and shaping tough materials like metal; the types of projects that CNC machining firms can tackle are restricted.

Risk of Equipment Failure: The possibility of equipment failure CNC machines, like any other type of machine, are subject to breaking down or otherwise malfunctioning, which can result in delays and additional expenditures for CNC machining firms and the consumers they serve.