Got Discoloration in Injection Molded Parts? Here’s How To Fit It!

Injection molding discoloration is a variation from the plastic’s base color. Overheating, contamination, and faulty production could all contribute to this faulty component. The degree to which a flaw in the part’s coloring due to thermal degradation is evident varies with the severity of the degradation. To avoid this problem, it’s important to have a […]

Flow Lines Defect in Injection Molding: Solving and Preventing a Common Injection Molding Defect

Due to its precision, several issues may arise throughout the injection molding process. The cosmetic or structural integrity of the part can be compromised by anything from operator error to flaws in the mold design. One common error manufacturers often face during this process is flow lines defect in injection molding. Now if you’re a […]

Analyzing The Occurrence of Injection Molding Weld Lines and Their Solutions

Injection molding weld lines refer to a line on an injection molded part that is generated where the two halves of the mold come together. As a result, the portion has a faint, perhaps undetectable line. This line does not normally impact the overall shape or dimensions of the item. Still, it can be seen […]

A Deep Analysis of Burn Marks in Injection Molding

“Burn marks” are a type of flaw in injection molded parts that manifest as a blackened edge near the very end of the cavity-filling process. Air that becomes trapped in the injection mold’s cavities causes burn marks. As the plastic was pumped into the mold, it compressed the air inside the cavities to the point […]

Injection Molding Machine Barrel For High-Precision Manufacturing: Manufacturing, Uses, and Properties

The plastic injection molding barrel is a cylindrical component that is integral to the injection molding machine. It is located between the plasticizing screw and the mold cavity. It serves as a chamber for melting and processing plastic materials. The barrel is typically made of heat-resistant materials, such as hardened steel or bimetallic alloys, to […]

How Is CNC Demolding Better Than Manual Demolding?

CNC demolding is the automated approach to getting parts out of an injection mold. This makes it easier for technicians to conduct the machining process effectively. While many technicians don’t have a detailed understanding of CNC demolding and how it works, a lack of understanding can lead to issues in the production process. As professionals […]

What Causes Ejected Mark In Injection Molded Parts & How Can You Solve It?

People typically define ejector pin markings as glossy or white impressions on the surface of an injection-molded object. These markings exhibit various levels of glossiness, including dark or shadow-like impressions without any convex or concave features. People can observe these markings directly opposite the ejector pin location. This detailed guide will explore the cause and […]

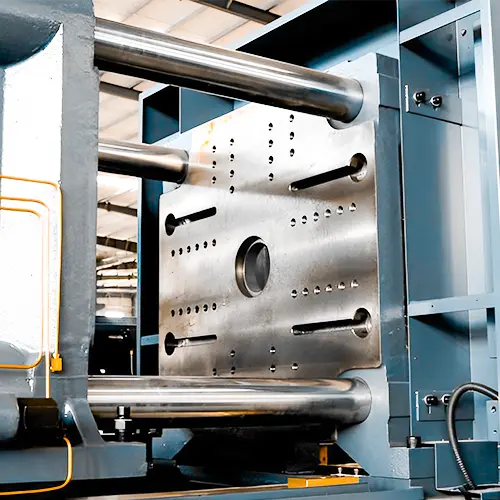

How Does an Injection Unit in Injection Molding Machine Function?

The importance of an injection molding machine cannot be overstated in the manufacturing industry, particularly in producing plastic parts and products. From efficiency to productivity, versatility, precision, consistency, cost-effectiveness, and much more – manufacturing with injection molding machines is common today for endless benefits. However, these benefits can only be availed if you know how […]

Guide Pin in Injection Molding: Enhancing Precision and Efficiency

Injection molding is a common industrial technique that facilitates the creation of complex and precisely crafted plastic components. Several parts work collectively to guarantee proper mold alignment and functioning. A guide pin is an essential part of these mechanisms. We will explore the usage and importance of a guide pin in injection molding, highlighting their […]

Sprue Bushing of Plastic Injection Mold: What You Should Know?

If you’re new to the world of injection molding in the production industry, the term ‘sprue bushing’ may confuse you. Simply put, it’s a component used in injection molding machines that plays a vital role in production. But there’s more to exploring how sprue bushing works and what should be considered to ensure the best […]