A Step-By-Step Guide on The Injection Mold Lifter Design

Designing a lifter for injection molding is a complex and technical process that requires careful consideration of many factors. A lifter is a small, movable component used to lift the molded part off the core side of the mold during ejection. It is a critical component in injection molding because it helps create complex geometries […]

Key Injection Mold Components You Should Be Familiar With

If you’re planning to produce a plastic part using injection molding, you’ll need to familiarize yourself with the essential injection mold components. From the sprue to the sub-runner and exhaust port, each component plays a vital role in the injection molding process. However, if you’re new to injection molding, you may find yourself lost in […]

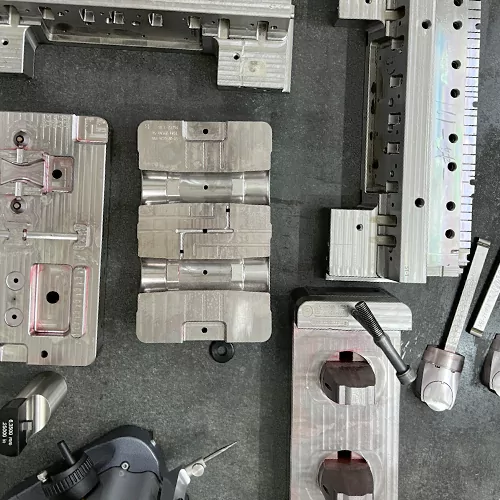

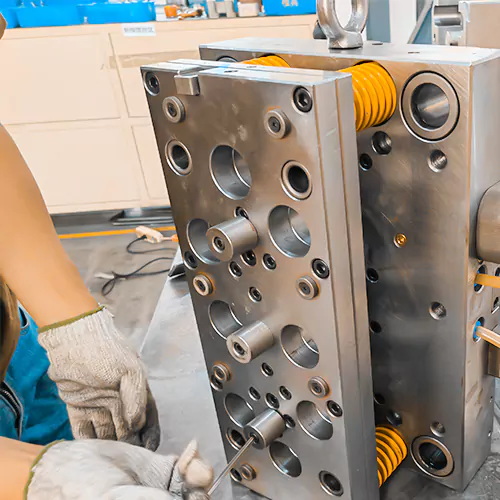

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. This article will […]

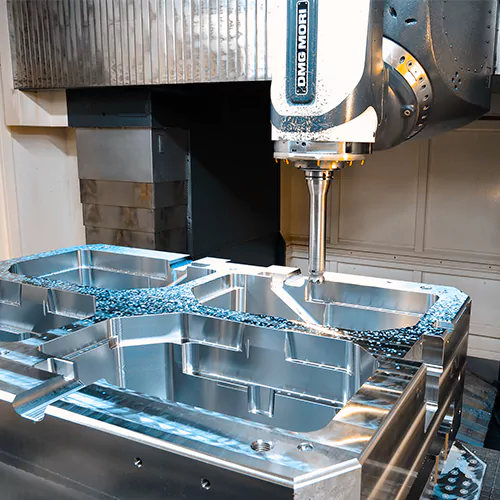

High-Quality Plastic Injection Mold: How You Can Enhance Mold Quality?

Are you curious how you can better manufacture high-quality plastic injection mold? The global plastic injection molded parts market is now worth $325 billion, with a 5.7% increase expected through at least 2025. Considering this growing adoption, it’s evident that one of the most notable advantages of plastic injection molding is the ability to produce […]

8 Tips to Reduce the Cost of a Plastic Injection Mold

When it comes to producing plastic components for various uses, one of the most widespread methods is known as plastic injection molding. Manufacturers need a plastic injection mold designed according to the product that needs to be produced. Now a typical question asked by those looking for a manufacturer is, “How much will the plastic […]

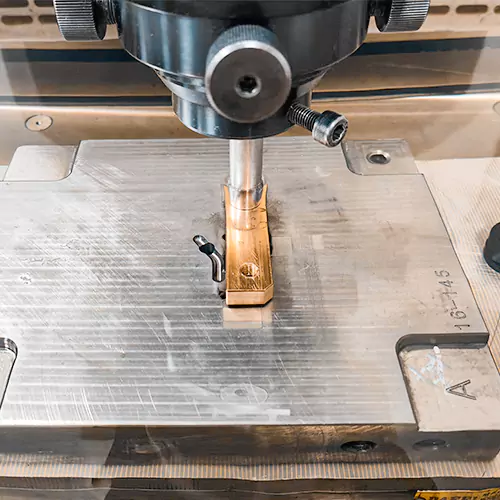

EDM Machining: Understanding the Operation, Characteristics, and Components

The costs of using standard production methods can skyrocket if you need unusual dimensions, materials, or other specifications for your manufactured product. Machining a block with bearing or component-holding openings and chamfers requires intricate milling, turning, and drilling. What if you create one or two parts for your prototype while still in the planning and […]

Die Tooling: The most commonly used processing equipment and processes

Being a fabrication process, die cutting uses specialized equipment and machine tools to cut, mold, and shear stock material into unique forms and designs. The die-cutting method is versatile and adaptable to various materials, including metal, plastic, wood, and composites. It is also used in various sectors for die-cutting neoprene, gasketing, paper, packing, die-cutting cloth, […]

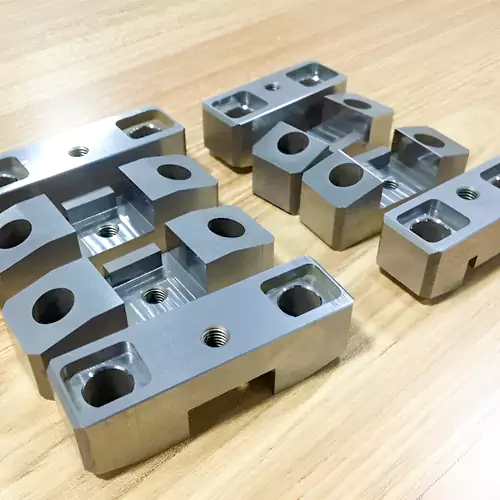

The complete introduction of mold parts

Injection molding is primarily a phenomenon in the manufacturing processes of plastic. It is a manufacturing process that involves shaping a liquid or malleable raw material with the help of a fixed frame, also known as a mold or a matrix. A mold is a hollow cavity receptacle, usually made of metal, into which liquid […]

How to design a hot runner?

Resource optimization and higher efficiency are integral parts of the molding industry. And a hot runner works as the most suitable tool to achieve both. Businesses use them to eliminate scarp plastic, providing faster cycle time and increasing. You can also achieve high quality by transferring the melt to the mold. Their hot tip and […]

How to Maintain Tool and Die?

During their daily operations, manufacturing sectors extensively use various instruments to ensure that they can produce a large number of items. They use a cutting tool and die, one of the instruments in their toolkit. A machine tool can mold work pieces into a profile or shape as a cut or die. Cutting dies can […]