Der Präzisionstest von Prototool: Bewertung von Auswerferstiften und -platten für Spitzenleistungen

The evaluation of the ejector plate in injection molding involves a comprehensive examination to ensure its precise alignment, proper functionality, and quality assurance. During testing, we meticulously check for visual defects and wear, and scrutinize the ejector pins’ performance to ensure smooth and damage-free part ejection. Manufacturers measure the force required for ejection to match […]

Lösung für Kleinteile im Spritzgussverfahren: Herstellung Ihrer bevorzugten Komponenten und Produkte

Join the Injection Molding Small Parts Solution Revolution! 🚀 We’ve got the perfect answer for crafting those tiny but essential components. Our team’s expertise and top-notch technology bring precision, quality, and affordability to your small part production needs. Whether it’s intricate designs or micro-sized wonders, we’ve got the magic touch to make it happen. Come […]

Die Verwandlung von Kunststoff in Magie: Der skurrile Tanz von 2X2-Mehrfachhohlraumteilen in einem Spritzguss-Wunderland

Multi-cavity parts enhance productivity, reduce costs, and ensure consistent quality by allowing the production of components in a single mold.

Double Shot: Die erstaunliche Reise des 2K-Spritzgießens

The 2K injection molding process involves injecting two different materials or colors into a single mold to create a layered or multi-material plastic part, enhancing design flexibility and functionality. This is achieved by sequentially injecting one material on top of the other in the same mold.

Wie man eine Spritzgussform auf einer Spritzgussmaschine installiert

Injection mold installation can also be referred to as “mold setup” or “mold mounting.” These describe the process of preparing and positioning the injection mold in the injection molding machine for production.

Sie fragen sich, wie das Spritzgießen von Kleinserien funktioniert?

The small batch injection molding cycle involves preparing material, melting, injecting, cooling, ejecting, cycling, quality control, and packaging.

Two Demolding Techniques: Manual demolding and Automated demolding Using Robotic Arm in the Injection Molding Process

Experience the efficient production of plastic parts with the injection molding machine. Make a distinguish between manual demolding and automated demolding.

Prepare to Have Your Mind Blown: The Epic Injection Molding Journey of Medical Hearing Aid Parts!

Get up close and personal with precise close-ups of how hearing aid headphones are molded!

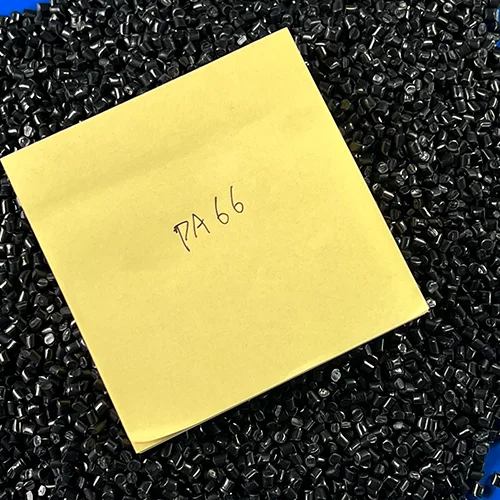

Polyamide Injection Molding Process Highlight: A Brief Overview

The beauty of plastic injection molding is that you may choose from various materials, each with advantages and disadvantages. Polyamide, better known by its brand name, Nylon, is one such plastic material frequently used in injection molding. This thermoplastic’s outstanding blend of electrical and mechanical qualities makes it a great choice for applications in various […]

Polystyrene Injection Molding | Plastic Injection Molding

Polystyrene injection molding is at the vanguard of modern manufacturing, providing an unrivaled mix of adaptability, cost-effectiveness, and ease of use. Polystyrene is a great example of the art of molding because it can be made into many different shapes, such as wrapping foams. Now, let’s learn more about the polystyrene injection molding technique. Characteristics […]