Steel is a common metal that is important in many businesses worldwide. Its versatility and strength make it a top choice for manufacturers aiming to meet precise product specifications. Among the various metal machining services, steel CNC machining is a highly automated and versatile process. Yet, achieving optimal results in machining steel requires a nuanced approach. In this article, we delve into the intricacies of CNC steel machining, providing essential insights to help you attain the best outcomes.

To get familiar with the CNC machining process, check out our detailed guide on machining parts.

The Different Grades of Steel Used for Steel CNC Machining

Selecting the right material is paramount in CNC steel machining, and steel offers a world of possibilities. But how do you pick the right steel grade for your project? Let’s explore some common steel grades and their properties to help you make informed decisions.

4140 Steel

With low alloy composition, including chromium, molybdenum, and manganese, 4140 steel boasts enhanced strength, flexibility, and corrosion resistance. It’s ideal for couplings, spindles, bolts, nuts, and automotive steel machined parts. However, welding may require pre- and post-heat treatment.

Mechanical Properties

| Properties | Value |

| Yield Tensile Strength (MPa) | 655 |

| Elongation at Break (%) | 19 |

| Density (g cm-3) | 7.87 |

| Shear Modulus (GPa) | 80 |

| Hardness (Brinell) | 197 |

4130 Steel

This grade, rich in alloying elements like chromium and molybdenum, offers excellent toughness, machinability, and stress resistance. It’s used in construction and aircraft engine mountings. Despite being heat-treatable, welding can be challenging.

Mechanical Properties

| Properties | Value |

| Yield Tensile Strength (MPa) | 460 |

| Elongation at Break (%) | 20 |

| Density (g cm-3) | 7.87 |

| Shear Modulus (GPa) | 80 |

| Hardness (Brinell) | 217 |

1018 Steel

Known as mild carbon steel, 1018 steel is prized for its weldability, making it a top choice for carburized CNC steel parts. However, it might not be compatible with all finishing processes and comes at a relatively higher cost.

Mechanical Properties

| Properties | Value |

| Yield Tensile Strength (MPa) | 310 |

| Elongation at Break (%) | 15 |

| Density (g cm-3) | 7.87 |

| Shear Modulus (GPa) | 78 |

| Hardness (Brinell) | 131 |

1045 Steel

A medium carbon steel, 1045 is strong, tough, and water-resistant. It’s used in various CNC steel machining projects, including axles, bolts, gears, shafts, and studs. While machinable and weldable, it’s not recommended for extremely robust products.

Mechanical Properties

| Properties | Value |

| Yield Tensile Strength (MPa) | 450 |

| Elongation at Break (%) | 12 |

| Density (g cm-3) | 7.87 |

| Shear Modulus (GPa) | 60 |

| Hardness (Brinell) | 170 |

1215 Steel

Featuring high sulfur content, 1215 steel is free machining and often used in automatic screw machine processes. It forms small chips during machining, allowing for higher machining rates. It’s suitable for heavy machining projects, such as studs, pins, screws, couplings, and hose fittings.

Mechanical Properties

| Properties | Value |

| Yield Tensile Strength (MPa) | 415 |

| Elongation at Break (%) | 10 |

| Density (g cm-3) | 7.87 |

| Shear Modulus (GPa) | 80 |

| Hardness (Brinell) | 167 |

Tools and Techniques Used for Steel Machining

Regarding steel machining, the right tools and techniques can make all the difference. Whether you’re exploring the process of steel CNC milling or tackling steel manufacturing, understanding the tools at your disposal is crucial. Here’s your comprehensive guide:

Hand Tools

- Accuracy: Good

- Cutting Time: Slow

- Finish of Cut: Good

- Cost: Low

Hand tools are a reliable choice for steel machining, offering decent accuracy and finish. However, they operate slower, making them ideal for small-scale projects with budget constraints.

CNC Mills

- Accuracy: High

- Cutting Time: Moderate

- Finish of Cut: Good

- Cost: Moderate

CNC mills shine in steel machining when precision cuts and excellent surface finish are paramount. They balance accuracy and speed, making them a versatile choice for various steel applications.

Water Jet / Laser Cutter

- Accuracy: Very High

- Cutting Time: Slow

- Finish of Cut: High

- Cost: Comparatively High

For thin steel workpieces demanding utmost precision, water jet and laser cutters excel. They offer unparalleled accuracy and produce high-quality finishes. However, they are comparatively costly and better suited for specialized tasks.

Plasma Cutter

- Accuracy: Good

- Cutting Time: Quick

- Finish of Cut: Good

- Cost: Moderate

Plasma cutters are the go-to for slicing through steel sheets up to 20mm thick swiftly and accurately.

The choice of tool depends on your steel type and project requirements. Stainless steel, with its alloying elements like chromium, can be challenging to machine. Opt for tools and inserts explicitly designed to enhance tool life and chip load for stainless steel.

Moreover, you can consider using carbide and high-speed steel tools for their robustness and abrasion resistance, enabling faster cutting and longer tool life. Lastly, tools coated with Calico Aluminium Titanium Nitride (AlTiN) are preferred for roughing and semi-finishing. At the same time, Titanium Aluminium Nitride (TiAlN) coatings excel in dry high-speed finishing and general machining.

Key Parameters to Consider for Steel Material Processing

Machining steel demands precision and the right parameters. Whether delving into steel machining services, precision steel machining, or steel CNC milling, nailing down these three critical factors is your key to success.

1. Speeds and Feeds

- Optimal Value: Moderate speed and feed for a balanced approach. Slow speed and feed for entry-level machines.

Speeds and feeds lay the foundation for smooth steel machining. Here’s the deal:

- Moderate Speed and Feed: Ideal for well-balanced machining, providing a smooth cut without excessive heat. Great for maintaining tool life.

- Slow Speed and Feed: Perfect for entry-level machines. Minimizes vibrations, ensuring excellent surface finish and precision.

- High Speed and High Feed: Recommended for roughing cuts for rapid material removal. Sacrifices surface finish for speed.

2. Cutting Tool

- Preference: Opt for a 2 or 3-flute end mill for efficient steel machining.

Steel is ductile and can produce long, clingy chips threatening your cutting tool. Here’s why a 2- or 3-flute end mill is your best bet:

- Chip Clearance: Fewer flutes prevent chip clogging, reducing the risk of tool breakage.

- Helix Angle: Higher helix angles work well for pockets, facilitating chip removal upwards. Lower helix angles are ideal for through holes, directing chips downwards.

3. Cutting Fluid

- Recommendation: Use cutting fluid to manage heat, extend tool life, and enhance surface finish.

Machining steel generates heat, which can wreak havoc on your tools and workpieces. Here’s how cutting fluid comes to the rescue:

- Heat Regulation: Cutting fluid keeps temperatures in check, preventing tool wear and workpiece damage.

- Chip Clearance: It flushes chips away, reducing the risk of chip re-cutting and tool damage.

- Higher Efficiency: A continuous flow of cutting fluid allows for faster cutting speed, deeper cuts, and quicker feed rates.

Choosing the right cutting fluid is essential:

- Soluble Oil Cutting Fluid (1:20): Ideal for high-speed machining with cemented carbide tools.

- Sulfochlorinated Mineral-Fatty Oil: Perfect for high-strength steel and tool steel operations like broaching and threading.

- WD-40 Sprays: Provide adequate lubrication for smaller DIY projects with smaller workpieces.

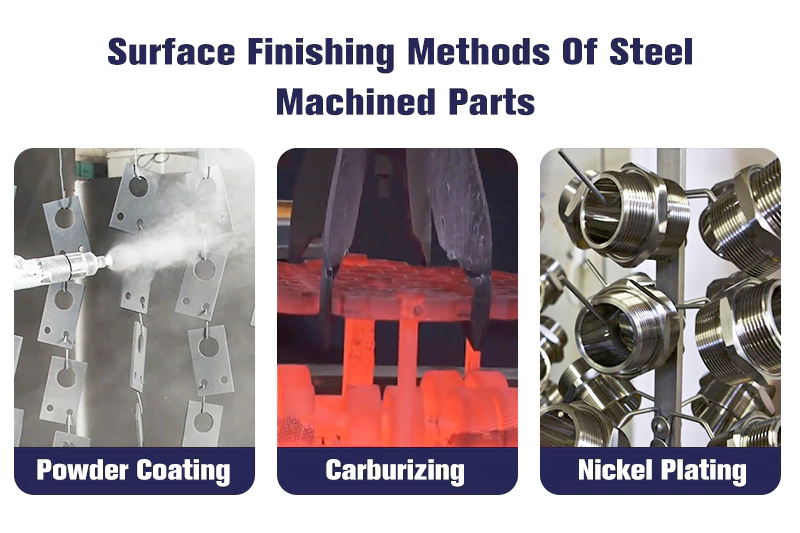

Surface Finishing Methods of Steel Machined Parts

Once you’ve manufactured the steel machined part, it’s time to get that perfect finishing to make the product ready to use. Below are a few surface finishing methods commonly considered for precision steel machining:

Powder Coating

Powder coating is a game-changer for your steel CNC milling. It’s like giving your components a suit of armor. A dry powder is expertly applied to the steel surface in this process, forming a robust layer.

This layer isn’t just for show; it’s engineered to withstand corrosion like a champ. The thickness typically ranges from 0.15 to 0.3 mm, ensuring your steel machine parts remain corrosion-free and resilient for the long haul.

Carburizing

When you need your steel machined parts to be tough as nails, carburizing is the secret weapon. This process involves heating the steel with carbon-rich materials, like carbon monoxide or charcoal.

What does it do? It transforms the surface of your CNC steel parts into an impenetrable fortress. The result? Exceptional hardness and resistance to wear. Carburizing doesn’t just make your parts durable; it ensures they can take a beating and keep on going.

Nickel Plating

For those times when you want both style and substance, nickel plating steps in. This surface finish takes your CNC steel parts to the next level. A thin layer of nickel, approximately 0.1 mm thick, is electroplated onto the steel’s surface.

The magic happens when this layer enhances the steel’s resistance to corrosion and wear. It’s like giving your parts manufactured through steel prototyping a polished, protective shield. Whether your steel components face the elements or heavy-duty wear and tear, nickel plating has covered them.

Grinding

Sometimes, it’s all about the finishing touch. Grinding is like the artist’s brushstroke that smoothens the rough edges and elevates the appearance of your steel parts. The steel’s surface is carefully refined using a grinding wheel, eliminating imperfections.

Eventually, you get a sleek, polished finish that looks great and ensures the steel meets your specifications. Whether it’s about aesthetics or precision, grinding is the final flourish that takes parts manufactured through steel prototyping to the next level.

Mastering Surface Finishes

Tips and Considerations: To master surface finishes, it’s essential to match the finish to the purpose. Each finish has a unique benefit – powder coating for corrosion resistance, carburizing for wear resistance, nickel plating for added durability, and grinding for a polished appearance.

Remember that precision steel machining often involves specific surface finishes tailored to the part’s function and design. And lastly, achieving the perfect surface finish requires expertise.

Conclusion

While steel machining is a crucial manufacturing process, mastering it requires attention to detail and the right techniques. Precision is key, from selecting the right steel grade to optimizing machining parameters and minimizing vibrations.

Don’t forget the importance of post-processing for that flawless finish. In your journey to achieve top-notch steel machining results, remember that Prototool is a trusted partner in the manufacturing industry.

With our expertise and dedication to quality, we’re here to offer top-notch steel machining services every step of the way. Your steel projects deserve the best, and that’s what we’re here to deliver.