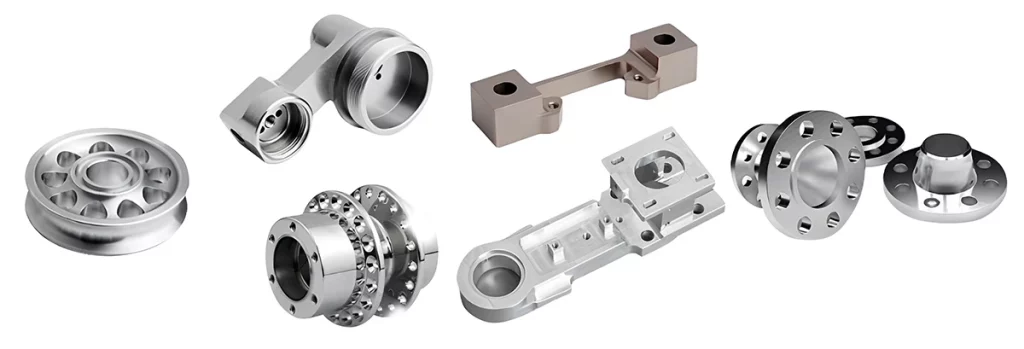

The machining part is the approach to creating objects that we utilize in our day-to-day lives. We rely on them a lot. They range in complexity from simple to sophisticated designs and are used as spare parts or tooling surfaces.

But how are these parts manufactured? In modern manufacturing, professional manufacturers help quickly and cheaply manufacture CNC-crafted parts.

In this article, we will go over everything regarding machined parts, from their features to the aspects that distinguish them from manufactured products, as well as their design guide.

What are Machined Parts?

Machined parts are used in various sectors, including simple metal fasteners and complicated aircraft engine components. Machining, at its core, is the manufacturing of specialized parts using cutting equipment such as mills, routers, and lathes.

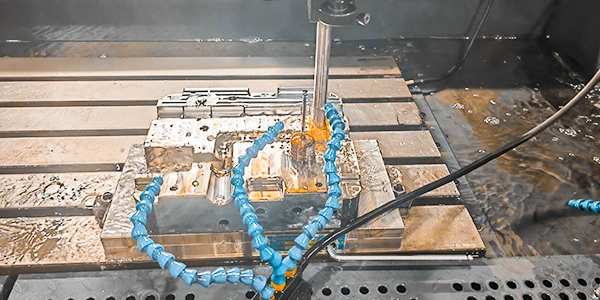

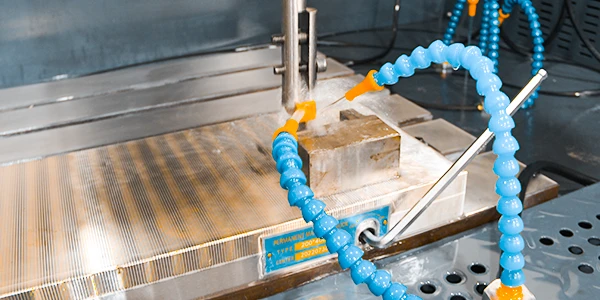

While their methods differ, they all have the same goal: to remove material from a solid block known as the workpiece using precision cutting tools.

Different methodologies can be used to produce a machined object. Manual part machining requires the knowledge of a trained machinist who manually uses machinery such as mills to form an accurate part crafted by milling.

On the other hand, CNC machining utilizes motorized CNC machines that autonomously execute cutting processes based on computer-generated instructions.

CNC machining, due to its accuracy and efficiency, is widely used in modern practices for delicate and customized products. However, manual machining remains popular for certain tasks because of its speed, especially when digital design and programming for CNC machinery are not required.

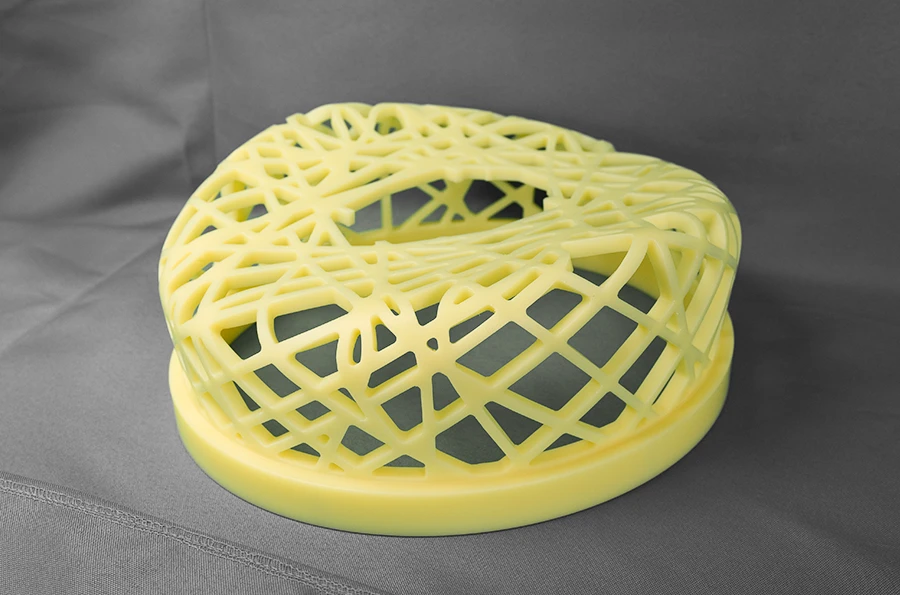

Now, in choosing materials for a CNC-crafted part, different materials are used – ranging from metals to polymers. Nonetheless, the material of choice must have the ability to be sliced without considerable distortion. Specifically, below are some material considerations that are ideal for machining part practices:

| Titanium Machining | Stainless Steel Machining | Magnesium Machining | Steel Machining |

| ABS Machining | POM Machining | PEEK Machining | Zinc Machining |

| Brass Machining | Copper Machining |

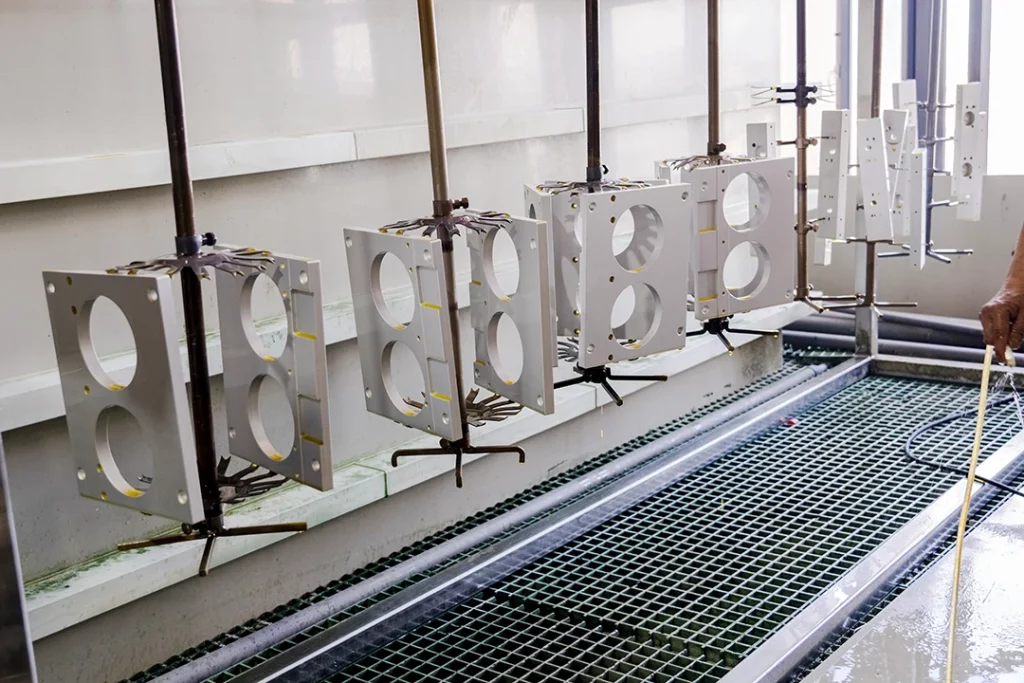

However, in some cases, part machining is done on items constructed using other procedures. For example, cast or molded goods may be subjected to additional machining to incorporate certain details or characteristics.

These components are known as partially machined or post-machined parts, demonstrating the versatility and adaptability of machining methods in various manufacturing circumstances.

Machining vs. Manufacturing: How is it Different?

Machining and manufacturing are two interrelated operations that play different functions in the production process. Manufacturing refers to various techniques to convert raw materials into final products, including casting, molding, forging, and machining.

Now, coming to machining, a subset of manufacturing, this process involves the controlled removal of material from a workpiece to obtain specified forms or features. This technology has extraordinary precision, allowing the fabrication of delicate elements that would be difficult or impossible to create using other procedures.

Why Use Machined Parts?

Various compelling reasons underpin the use of machined parts in many industries, including those driven by enterprises, product designers, and research and development (R&D) departments. Below, we will shed some light on the various applications and benefits of a machined piece, which makes it useful in real-world environments:

Inherent Strength

Because machined parts are made from solid blocks of material, their inherent strength is a significant benefit. This strong base provides these components with excellent endurance and robustness.

Furthermore, the versatility of machined parts is demonstrated by their ability to assume a wide range of shapes and thicknesses. This versatility allows for complicated designs and varied proportions adapted to specific needs.

Precision Improvement

Another remarkable feature of machining parts is the precision of parts manufactured after machining. Their manufacturing approach enables the insertion of elaborate and highly detailed features, which improves the end product’s functionality and attractiveness.

Moreover, the variety of materials that can be used adds to the adaptability of machined parts. Metals, polymers, and even certain composite materials are among the available material alternatives.

Small Batch Production

Notably, machined parts significantly benefit in faster small numbers production. The lack of complex tooling requirements speeds up the manufacturing process, allowing for the production of small numbers as needed. This production agility aligns with the requirements of quick prototyping and low-volume production scenarios during machining parts.

Tight Tolerance

Machined parts can be produced with extremely tight tolerances. Controllable cutting rates enable fine modifications, allowing the final product to meet rigorous tolerances. This precision is useful in industries where precision is critical, such as aerospace and medical equipment manufacture.

Reliable Technique

Incorporating machined parts into projects also introduces the advantage of CNC-crafted parts with time-tested character as a production technology. Precisely, machining, as an industry standard for decades, provides dependability and predictability.

So, machined components are poised to align with industry-specific standards and certifications, enhancing their viability for various applications.

Best Practices for Designing Machined Parts

Below is a precise guideline to consider during the designing phase when machining the part:

Inside Corner Radii

When designing machined parts, keep inside corner radii in mind. Sharp corners should be avoided since they can cause tooling concerns such as excessive tool wear, increased machining time, and probable part damage.

Here, the optimal radius is determined by the material. Consider radii of 0.5 mm to 2.0 mm (0.02 inch to 0.08 inch) for softer materials such as plastics. Metals typically range from 1.0 mm to 3.0 mm (0.04 to 0.12 inch). Larger radii, such as 3.0 mm to 6.0 mm (0.12 inch to 0.24 inch) or more, may be required for machining parts with higher weights or a part requiring additional strength.

Pockets

Remember to consider the pocket depth and wall thickness when designing pockets. In general, strive for a pocket depth of 2 to 4 times the diameter of the cutting tool. Check that the wall thickness is 1.5 to 2 times the diameter of the cutting tool. This aids in structural integrity and efficient machining.

Cavities

Cavities are necessary within parts for various functions, such as housing components or forming interior structures. Consider the cavity’s function and design its size and form accordingly. This assures appropriate performance and manufacturing convenience.

Pre-Drill Tapping Depth

When incorporating threaded holes into your design, precisely specify the pre-drill tapping depth. This depth determines the threaded portion’s engagement. Make sure that the pre-drill tapping depth corresponds to the threading requirements, including thread size and pitch.

This is important because precision requires adhering to industry standards or consulting a machinist.

Tapped Holes

Consider thread size and pitch based on the application’s requirements when designing items with threaded holes. Choose a hole diameter large enough to accept the thread diameter and allow optimal contact.

Consult engineering references or professional machinists at Prototool for suggested hole diameters for specific thread types. Include a thread relief at the bottom of the hole to ensure proper thread formation and prevent binding.

Undercuts

Including undercuts necessitates paying close attention to draft angles to ensure smooth ejection during production and prevent part damage. Ensure that machining tools can reach and mill undercut areas, which may need specialized tools or multi-axis procedures. This aids in the creation of accurate interlocking systems.

Wall Thickness

Maintaining correct wall thickness is essential for structural integrity and manufacturability. Investigate the qualities of the material to establish the minimum needed thickness.

To avoid stress concentration and subsequent warping, maintain uniform wall thickness throughout the part. Consider adding support structures or ribbing to improve rigidity, especially for big or thin portions.

Text and Lettering

Use a clear and readable typeface when incorporating text or lettering on machined parts for identification or branding. Consider the legibility of the typeface at the desired size and avoid extremely complex styles that may be difficult to machine accurately. To ensure accuracy and legibility, specify character size concerning the total dimensions of the part.

Determine the necessary depth of text or writing for the intended visual effect. Depending on the material and application, consider surface treatments such as engraving or etching to improve visibility.

Surface Finish

Based on the process of machining the part, choose a surface finish that is suitable according to the part’s usage. Different methods produce different finishes, which influence both aesthetics and functionality. To get the desired result, ensure the chosen finish is compatible with the product’s intended purpose and manufacturing process.

CNC Machined Parts Examples:

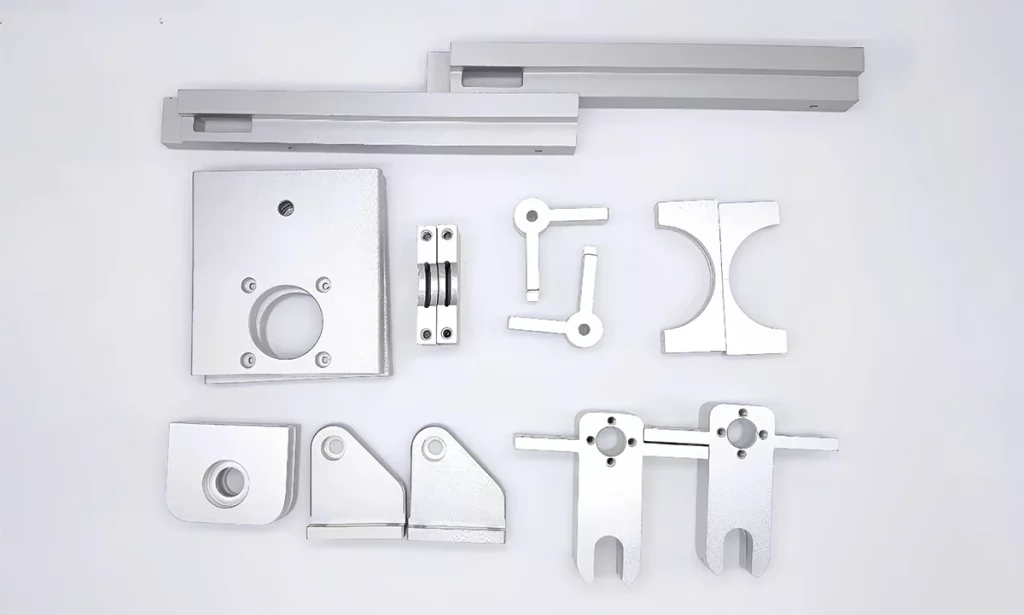

CNC-crafted part machining produces a wide range of machined parts, demonstrating its versatility and precision. Here are a few noteworthy examples:

- Fittings Components: Fittings are critical components that ensure the flawless connection of diverse parts. Accurate dimensions are critical since any miscalculation can weaken the connection, perhaps leading to failure. CNC machining guarantees accurate fitting construction, contributing to the assembled system’s overall reliability.

- Ball Joints: Inspired by the ball and socket joints of the human skeletal system, ball joints allow components to move in multiple directions. Ball joints that have been CNC machined allow components to pivot and rotate at different angles. This design consideration is invaluable in applications requiring dynamic movement and flexibility.

- Metal Brackets: Metal brackets help support machinery sequences. Precision and personalized design can be found in custom-machined metal brackets made with CNC machines. These brackets provide strong support, enhancing machine stability and functionality during CNC machining.

—-

Prototool is a prototype and custom part manufacturing company with a vast track record of machining parts by turning parts and milling parts. Get a quote for your next machined parts order today!