According to Fortune Business Insight, the global CNC machine market was estimated to be worth USD 83.99 billion. This market is further expected to grow to USD 140.78 billion by 2029. That said, CNC machines are common automated machines manufacturers use to process materials and create diverse products. But how do you know which CNC machine suits your product’s production demands? Specifically, common machines like CNC routers and CNC mills help make manufacturing tasks easier and more efficient. For choosing one of these machines, it’s important to understand their differences and cost estimates. In this guide, we will discuss a detailed comparison between CNC mill vs. router and how these machines differ in price.

So keep reading to learn all about these CNC machines.

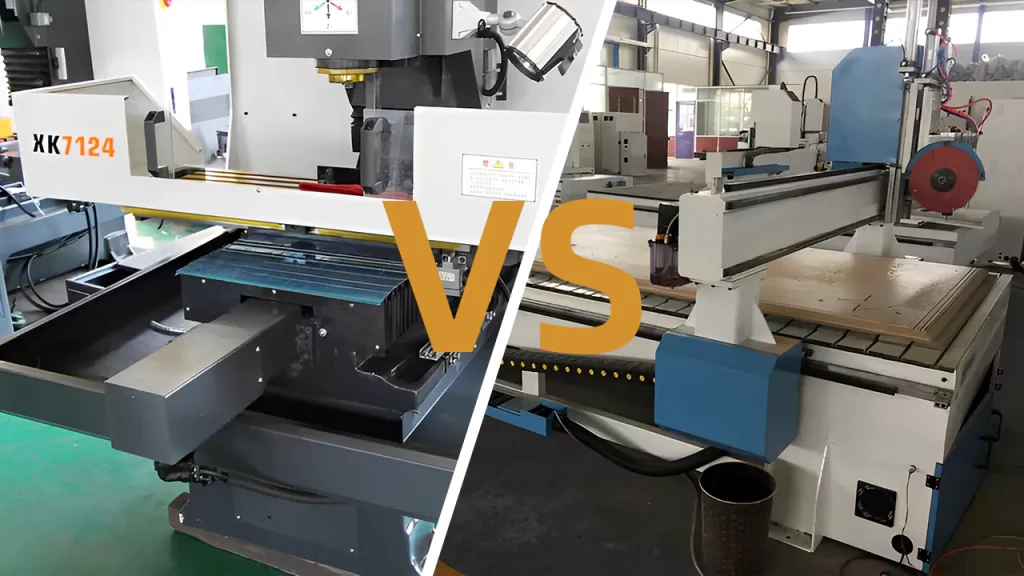

Understanding CNC Mill and Router:

Mills and routers are CNC (Computer Numerical Control) devices used to cut and shape materials such as wood, metal, and plastic with high precision.

So, what on earth is the difference between a CNC mill and a router? While they may appear the same, there are a few crucial variances. CNC mills are designed to move in three or more axes and are often used for cutting tougher materials such as metal. They can perform various activities, such as drilling, tapping, and boring. On the other hand, Routers are designed to cut softer materials such as wood and plastic and typically move in three axes. They are also more suitable for engraving and sculpting.

CNC mills and routers use a spinning cutting tool to remove material from the workpiece, but the tools differ. Milling machines use a high-speed rotating cutting tool, whereas routers use a spinning spindle with a cutting tool attached.

Also Read: Ceramic Manufacturing: What It Is, The Process, and Key Considerations

Apart from these differences, various advantages, working properties, and cost differences add to the comparison of CNC mill vs. router. In this detailed article, let’s go ahead and explore that below in detail.

Comparison Table: CNC Mill vs. Router

If you’re unsure which CNC machine you should choose, below is a detailed comparison table of CNC Mill vs. Router.

| Features | CNC Mill | CNC Router |

| Design and Structure | Milling machines controlled by a computer have a sturdy and solid frame constructed out of cast iron or steel. When cutting tougher materials like metal, it is necessary to have a design that helps absorb vibration and ensures stability during operation. This design helps achieve both of those goals. The cutting tool is fixed on a spindle that allows it to travel in all directions, including forward and backward, side to side, and up and down. This motion is managed by precision linear guides and ball screws, which make it possible to place things in a manner that is both exact and consistent. The workpiece is supported by a table capable of movement along three or more axes, enabling great flexibility and variety. In addition, the table is often outfitted with T-slots or other mounting elements that make it simple to secure the workpiece in place and adjust its orientation. CNC milling machines can be fitted with a broad variety of cutting tools, such as end mills, drills, and taps. As a result, these machines are extremely versatile and can be adapted to perform a wide range of machining processes. | The frames of CNC routers are often composed of aluminum or composite materials, contributing to their reduced weight. This design provides faster acceleration and slowdown, which is useful when cutting softer materials like plastic and wood. This design also allows for faster acceleration and deceleration. The cutting tool is fixed on a spindle that allows it to travel in all directions, including forward and backward, side to side, and up and down. Moreover, precision linear guides and ball screws control this movement. The piece of work is supported by a mobile table along three axes, enabling significant flexibility and adaptability. In contrast to the tables on milling machines, the one on a router is not normally intended for heavy-duty cutting and may not be as sturdy. CNC routers often come outfitted with various cutting tools, such as router bits, drills, and saw blades. As a result, these machines are extremely versatile and can be adapted to perform a wide range of cutting operations. |

| Functionality and Movement | CNC milling machines are specifically intended to cut and shape tougher materials like metal, and they accomplish this by removing material from the workpiece using revolving cutting blades. They can move along three or more axes, enabling great precision and diversity in their operations. A computer, which receives instructions from a program written in CAD/CAM software, controls the movement of the cutting tool. CAD/CAM software was used to write the program. | CNC routers are designed to cut through softer materials such as wood and plastic and typically operate along three axes. They use a spinning spindle with a cutting tool attached to remove material from the workpiece. A CAD/CAM program provides the instructions a computer uses to control the movement of the spindle, which is also controlled by the computer. |

| Accuracy and Precision | The structure of CNC milling machines allows for extremely accurate and exact movement of the cutting tool, which is important for creating complicated shapes and features with tight tolerances. Additionally, CNC milling machines typically feature improved tool holders and high-speed spindles, which enable the machine to maintain accurate tool positioning and stability despite the high cutting speeds at which it operates. This makes cutting more quickly and efficiently possible while preserving high accuracy and precision throughout the process. | When cutting tougher materials, the lighter frame, less robust linear guides, and ball screws used in constructing CNC routers result in poorer accuracy and precision than milling machines. However, contemporary CNC routers typically come outfitted with cutting-edge technologies such as high-precision servo motors and closed-loop feedback systems, which can correct any positioning imperfections and keep the tool in an accurate position. Because of this, cutting can be done in a manner that is extremely accurate and precise, particularly when utilizing specialist tools such as diamond-tipped router bits. |

| Speed and Power | CNC milling machines are primarily built to cut tough materials such as metal, so they are frequently equipped with powerful motors and high-speed spindles. This makes cutting possible at a higher speed and more efficient, particularly when utilizing specialized tools such as carbide end mills. In addition, the construction of their heavy, robust frames includes high-precision linear guides and ball screws, which enable faster acceleration and deceleration. This can assist in minimizing the amount of time needed for machining, which in turn can help to enhance productivity. | Since CNC routers are often intended for cutting softer materials such as wood and plastic, these machines may not require the same degree of power as milling machines. It’s primarily because of the nature of the materials that they are designed to cut. Nonetheless, newer routers typically come equipped with powerful motors and high-speed spindles, allowing quick and precise cutting despite the machine’s age. Moreover, the design of these machines features a light frame, which allows for faster acceleration and deceleration and less rigid linear guides and ball screws. This design helps reduce the time needed for machining and boosts productivity, particularly when cutting softer materials. |

| Application | CNC milling machines help manufacture parts and products that help in the production industries like aerospace and defense, automotive, and medical. Some common products such machines help manufacture include engine parts, turbine blades, missile components, cylinder heads, engine blocks, joint replacements, surgical tools, and more. | These machines help manufacture different parts and products that we can find in the production industries, like plastics, woodworking, and signage. Some common parts and products that this machinery helps manufacture include wooden furniture, musical instruments, signage logos, carved decorative signage, display cases, toys, etc. |

Cost Comparison:

Today, some brands and companies offer different price ranges for CNC mill vs. router models. Hence, the cost of a computer numerically controlled (CNC) router or mill differs based on the brand, quality, and size of the machine you buy. However, in most cases, you can anticipate that CNC routers will be less expensive than CNC mills of an equivalent grade.

Why is that? Because you can purchase CNC routers for as little as two hundred dollars or as much as one hundred thousand dollars for industry-level capability. In contrast, CNC mills normally cost more than $1,000, even for the brands that are considered to be the most economical, and they can cost as much as $150,000.

Conclusion:

The advantages, applications, use cases, and production capabilities of the CNC mill vs. router are endless. However, understanding the basic differences between the two machines can help make a smarter production decision for your business or products.

Still have queries? Contact our experts at Prototool.com.