In the old days, people had no machining technologies and tools. Maybe a chisel and hammer were the exceptional tools that they had. But employing them at this advanced age would take years to complete a whole batch for a car manufacturer. Just imagine what Michelangelo could have done if he had access to CNC machining technology. Maybe he carved out his famous David statue using a hammer and a chisel. But this in no way seems a viable, practical approach to fulfilling today’s manufacturing requirements. If you want to carve your business idea into practicality, you need the best-in-class tools and technology. So that you can always stay ahead of your competitors and leverage the market opportunities in time. When it comes to fabricating parts with your required attributes, then 5-axis CNC machining can produce the best and speediest outcomes for your next project.

What is 5-Axis CNC Machining?

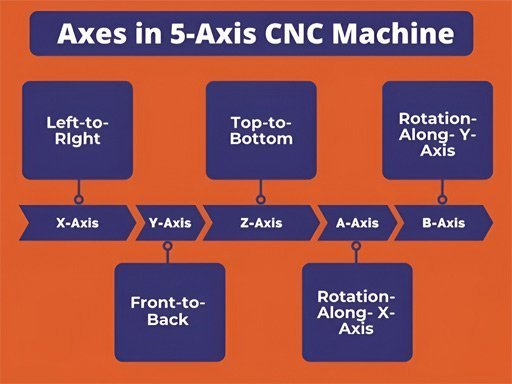

Computer numerical control machining is used to manufacture high-precision custom-designed parts. It subtracts the workpiece using highly efficient precision machines and various tools. A 5-axis CNC machine has two additional axes compared to a 3-axis machine, i.e., rotation around the x-axis and y-axis. In comparison, a 3 axes machine can only move along three linear axes. It can manipulate the workpiece or tool from all 5 axes in a single operation.

We can configure these five axes into two styles. The first style incorporates the rotatory tables, and the second configures rotary axes into the machine’s headstock and spindle. The ability of 5 axes precision machines to rotate along two linear axes empowers them to produce highly intricate geometrical parts in less time, economically, and efficiently.

What are the Axes in 5-Axis CNC Machining?

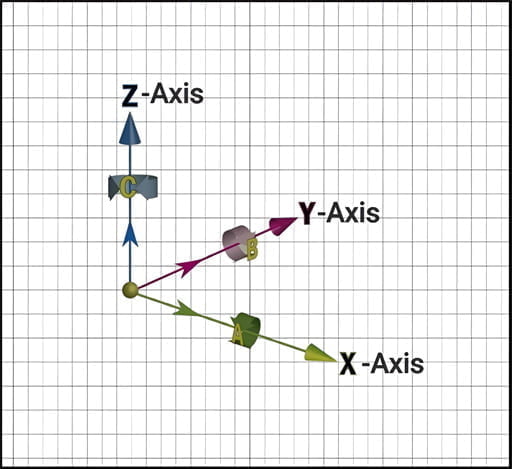

The first three axes out of 5 axes are the same as a three-dimensional Cartesian coordinate system, which was developed by the French philosopher, mathematician, and scientist, René Descartes. A buzzing fly was the reason behind the invention of this Cartesian coordinate system.

Descartes was resting in his room. Suddenly he saw a fly in the air and thought about determining his position. He just described the position of the fly by using the three-dimensional space of the room, which he represented through three measurement variables, X, Y, and Z. These same variables are employed to describe the 3-axis of a 5-axis machine.

Now imagine that Descartes’ fly is rotating along a linear axis instead of moving in three-dimensional space. Just conceive the rolling fly as the workpiece not moving linearly but rotating. And we are concerned about calculating its rotational movement.

Fly’s or blank’s rolling movement can be narrated with the help of two extra axes, i.e., 4th and 5th, denoted by ‘A,’ ‘B,’ or ‘C’ in the graph above. A is the rotation along X-Axis when the blank tilts forward and backward, and B represents the rotation along Y-Axis when the blank spins and tilts left to right.

Different Configurations of 5-Axis

We can configure the axes of a 5-axis CNC machine in two ways. One is swivel rotate style, and the other is trunnion style. Which axis configuration is to be used depends on certain requirements like the parts’ weight and volume.

Swivel Rotate Style:

When we configure axes in a swivel rotation style the machine operates with a B-axis and a C-axis. The first axis enables the device to rotate along the Y-axis and the second axis equips the machine’s movement along the Z-axis.

To harness rotatory axes, the swivel rotate style machine rotates the spindle. While this style is ideal for machining heavier parts as the table remains horizontal continuously.

Trunnion Style:

In trunnion style, we always configure the machine along the A-axis and C-axis, allowing the machine to rotate along the X-axis and Z-axis, respectively.

Whereas in this axis configuration style, the machine harnesses the rotatory axes by moving the tables. Trunnion style offers its own distinct merits. In comparison, this is suitable for manufacturing parts in large volumes.

How Does a 5-Axis CNC Machine Work?

A 5-axis CNC machine turns a raw blank into a custom-designed excellent quality product with the help of a tool, which can move in three linear directions and rotate along with two of the three axes. It makes the machining process agile, efficient, and cost-effective. At the same time, it frees the operator to reposition the blank during the automation process.

Like every precision machine, a five axes CNC machine also relies on a 3D CAD design, CAM programming instructions, and a seasoned operator to oversee the whole process. After the creation of the part design, next comes the G-code, which controls the linear movement of the cutting tool as well as the motion of the worktable along the rotary axes.

The provision of tools, lubrication, and other important things are already taken care of. When the process ends, we’ll have a beautifully fabricated part.

Applications of 5-Axis CNC Machining in Different Industries

5-axis CNC machining finds its widespread application across numerous industries. It is particularly preferred in sectors that require products with intricate shapes and tight tolerances. Some industries taking advantage of this highly advanced technology include:

- Aerospace Industry

- Automotive Industry

- Medical Industry

- Energy Industry

- General Goods

The Benefits of 5-Axis CNC Machining

There are innumerable benefits of 5-axis CNC machining. The most important ones are listed below:

Single Machine Setup

The first and foremost benefit of a 5-axis machine is its ability to perform complex tasks with a single setup. This, in turn, saves time and the hassle of changing the setup, reduces the cost, and improves efficiency. 3-axis machines, on the other hand, require multiple setups. This leads to a waste of time, increases cost, and might lead to incorrect alignment and hence leads to poor quality. Thus, using a single setup is an essential benefit of 5-axis CNC machining.

Outstanding Processing Accuracy and Efficiency

Another benefit of 5-axis CNC technology is its enhanced processing accuracy and efficiency coupled with cost-effectiveness. The reason is that it involves little human intervention, and the machine uses all five axes simultaneously to yield better quality and precision. All of this reduces material debris and the cost of operation. In short, the 5-axis CNC technology is more efficient and accurate.

Shorter Cutting Tools

The next advantage of 5-axis technology is that it allows you to use shorter cutting tools. The reason is that it will enable you to lower the head and position the cutter aptly. This, in turn, leads to a higher cutting speed without putting higher pressure on the cutter.

Apart from a higher cutting speed, the shorter cutting tools also reduce the tool’s vibrations. Resultantly, the finished surface will be smoother. So, 5-axis machining allows you to use shorter cutting tools which offer several benefits.

Better Surface Finish

In order to bring off a smooth surface finish, the minimum possible distance is recommended between the cutting tool and the workpiece. Because when speed increases, the blank might be susceptible to vibrations contributing to a poor surface finish. The distance can be reduced with the help of rotational axes.

Ability to Fabricate Complex Parts

Another benefit of 5-axis machining is that it allows you to machine highly complex parts easily. Conventionally, such complex parts are possible only through casting, which also requires several months. But with 5-axis machines, the time drops down to a few weeks. Thus, 5-axis machining allows you to make complex parts conveniently.

Improved Tool’s Life

The use of 5-axis machining leads to enhanced life of machine tools. That is possible because it allows you to keep a constant chip load along with the optimum cutting position. Hence, 5-axis machining improves the lifespan of machine tools.

Convenient Hole Drilling

Another benefit of 5-axis machining is that it allows you to drill a series of holes with various compound angles promptly. Thus, it saves time and money and increases efficiency. Because in the case of a 3-axis machine, you would require to use a different setup for each hole. That would lead to a waste of time and money and might reduce efficiency. Thus, 5-axis technology ensures convenient hole drilling.

Conclusion

5-axis CNC is an exceptional machining technology. It offers many benefits and is utilized by numerous sectors in the world. The provision of two extra axes renders five axes machining the ability to rotate the tool along five-axis in a single operation.

This article discusses what you need to know about 5-axis precision machining. It explains all five axes in detail, two different configurations of the axis, and its working. The benefits are also elaborated on in the end.

If you need to fabricate your products as per your business requirements, then you can rely on Prototool, a respectable and trusted name in manufacturing and prototyping. Just reach out to us then we’ll take care of your product for you.

Prototool has served numerous industries. We greatly value our customers and their business needs. To commensurate our workshop with the evolving CNC technology, we invest huge capital in equipping our facility with the latest CNC machines and other technologies. So we can come up with our customer’s expectations.

We have a great team of highly skilled and passionate designers, programmers, engineers, and technicians, who are ready to serve you with the best CNC machining services.