In mold types commonly encountered, we find the two-color mold, overmolding, and family mold. These molds are categorized based on specific characteristics and functions, each offering unique advantages in the production process. Today, I will introduce eight types of injection molds classified according to the structure of the mold. It’s important to understand that the mold structures we produce for our clients are based on these eight foundational types.

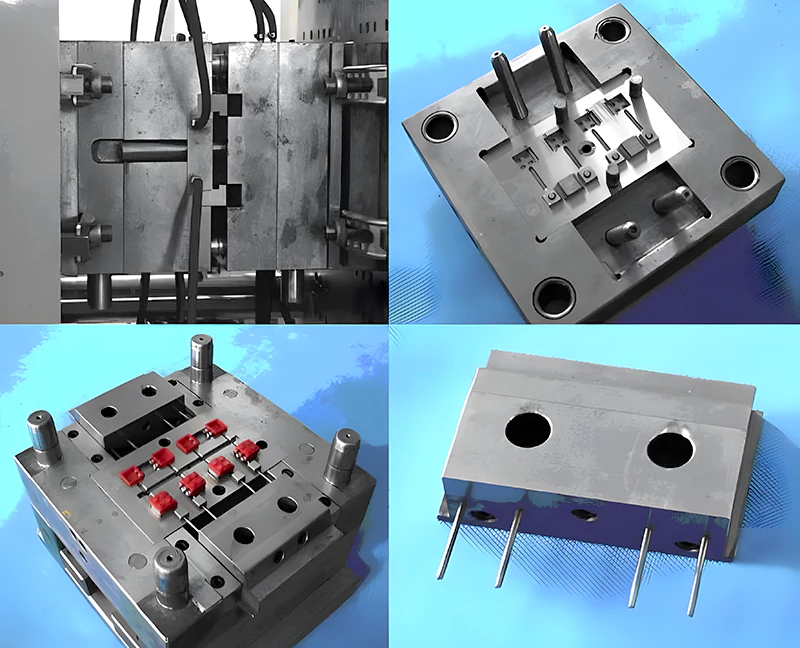

1. Single Parting Surface Injection Mold

When the mold opens, the movable and fixed molds separate, allowing for the removal of the plastic part. This mold is a single parting surface mold, also known as a two-plate mold. It’s the simplest and most basic form in injection molding, adaptable as a single cavity or multi-cavity mold, making it the most widely used type.

2. Double Parting Surface Injection Mold

The double parting surface injection mold features two parting surfaces. Compared to the single parting surface mold, this type adds a movable middle plate (also known as an active gate plate with gates, runners, and other necessary components) to the fixed mold section, hence also called a three-plate mold (movable mold plate, middle plate, fixed mold plate). We often use it for single or multi-cavity molds with point gate feeding. During mold opening, the middle plate separates a fixed distance from the fixed mold plate on guide pillars. This separation allows for the removal of the runner system.

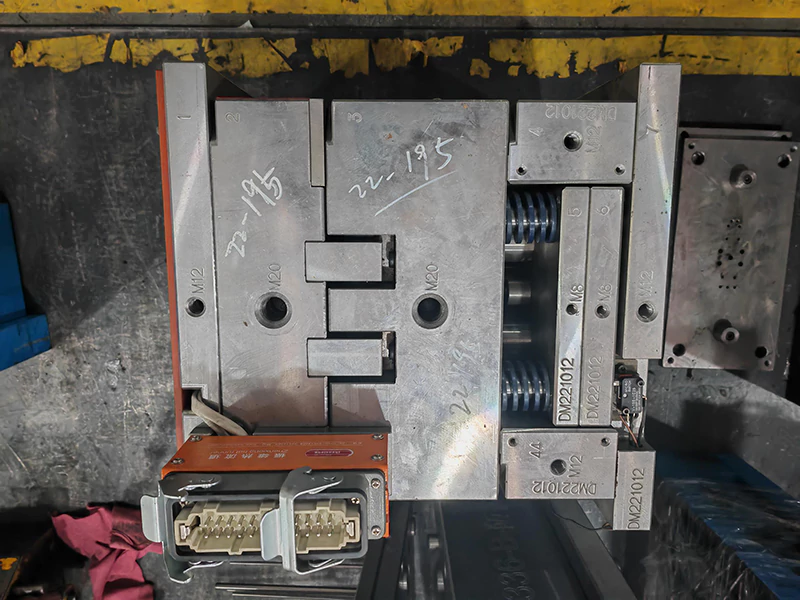

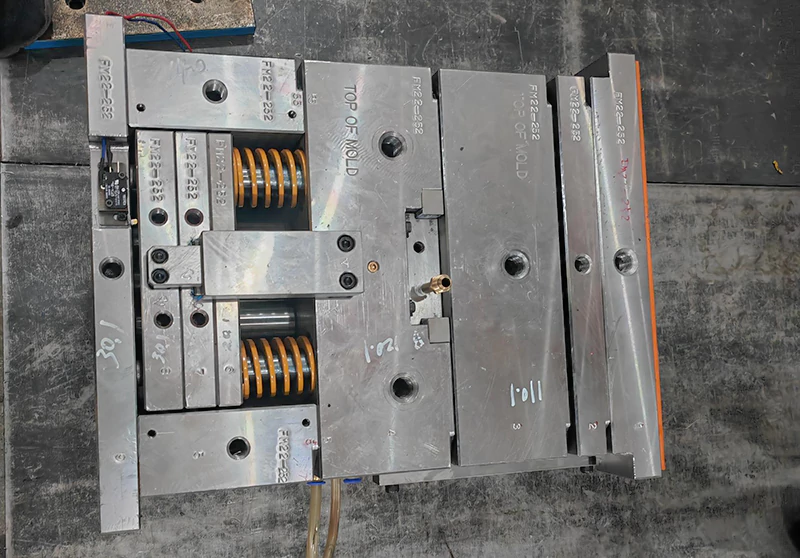

3. Injection Mold with Lateral Parting and Slider

For plastic parts with side holes or undercuts, a laterally slider is used for molding. After injection molding, the core first moves downward. Then, the oblique section of the pin fixed on the cavity plate forces the slider to move outward. Simultaneously, the demolding mechanism’s push rod pushes the push plate to eject the plastic part from the core.

4. Injection Mold with Movable Molding Components

Some plastic parts have special structures requiring movable molding components in the injection mold, such as movable core, movable cavity, movable inserts, movable threaded cores, or rings. These components move out of the mold with the plastic part during demolding and then separate from the part.

5. Automatic Thread Unloading Injection Mold

For threaded plastic parts requiring automatic demolding, the mold can be equipped with a rotatable threaded core or ring. Utilizing the mold opening action, the injection molding machine’s rotating mechanism, or a dedicated transmission device, the threaded core or ring rotates to release the plastic part.

6. Hot Runner Injection Mold

A hot runner mold uses an insulating heating method to keep the plastic between the injection molding machine’s nozzle and the mold cavity in a molten state, eliminating the need for a runner system in the mold. This type includes insulated runner molds and hot runner molds.

7. Right Angle Injection Mold

The right angle injection mold is exclusively for angle injection molding machines. Unlike other molds, the feeding direction during molding is perpendicular to the mold opening and mold closing direction. Its main runner is located on the sides of the mold core and mold cavity parting surfaces, usually with a constant cross-sectional area, differing from molds used in other injection machines. To prevent wear and deformation between the injection machine’s nozzle and the main runner inlet, a replaceable runner insert can be used.

8. Injection Mold with Demolding Mechanism on the Mold Cavity

In most injection molds, manufacturers install the demolding device on the mold core side to facilitate the ejection system in the injection molding machine. However, in practice, due to the shape of some plastic parts, it’s better to keep the part on the mold cavity side for molding. To demold the part from the mold, we must set up a demolding mechanism on the mold cavity side.

Conclusão

In summary, the world of injection molding is diverse and complex, with each of the eight types of injection molds serving a unique purpose in the manufacturing process. From the straightforward single-parting surface mold to the intricate hot runner and right-angle molds, each type offers specific advantages and applications. As technology advances, these types of injection molds will continue to evolve, further enhancing the capabilities and possibilities within the realm of injection molding.