As businesses keep pushing the limits of engineering and design, titanium has become a very popular material because of how strong it is, how light it is, how resistant it is to corrosion, and how well it works with living things.

It is used in many different fields, from aircraft para medical implants. But the great qualities that make titanium so appealing make it hard to work with. In this article, we will take you through all things titanium machining – from the properties to popularity and tips/tools used for effective titanium machining.

So, keep reading to learn how our professionals at Prototool suggest the mechanism of titanium machining. You can also read our guide on the machining part to learn more about the CNC-part machining process on different materials.

The Popularity of Titanium Machining in the CNC Part Manufacturing Industry

Titanium is a popular material for CNC part machining because it has several great qualities. It is a great choice for various uses due to its low mass, high strength, and corrosion resistance. Notably, titanium is twice as strong as alumínio, which makes it a great choice for situations with a lot of stress where strong materials are needed.

Likewise, titanium is often put up against steel, but it is 30% harder and almost 50% lighter. It is also naturally corrosion-resistant due to the formation of a protective oxide layer when titanium is exposed to air.

Additionally, titanium has a very high melting point of 3,034 degrees Fahrenheit, much higher than aluminum’s melting points (1,221 degrees Fahrenheit) and tungsten (6,192 degrees Fahrenheit). This makes it a popular material used in medical implants because it works well with bone. This popularity adds to its strong name in the CNC part machining industry.

But is it the same when comparing titanium with other popular parts used in CNC part machining? Probably not! Titanium cutting differs from stainless steel and magnesium due to its challenges and benefits. This makes the manufacturing process even more complicated.

This makes stainless steel and magnesium machining equally popular in the CNC part machining approach, catering to different production needs. Refer to these guides to learn more about stainless steel machining and magnesium machining.

Varieties of Titanium Used in CNC Machining

Today, titanium is available in various grades, including almost 40 ASTM grades and several other alloys. Some popular grades commonly considered during titanium machining include:

- Grade 5: The most prevalent is grade 5 (Ti6Al4V or Ti 6-4), which contains 6% aluminum and 4% vanadium.

- Grade 1-4: Commercially pure titanium is classified as grades 1 through 4, with varied specifications for ultimate tensile strength.

Why is Titanium Machining Difficult?

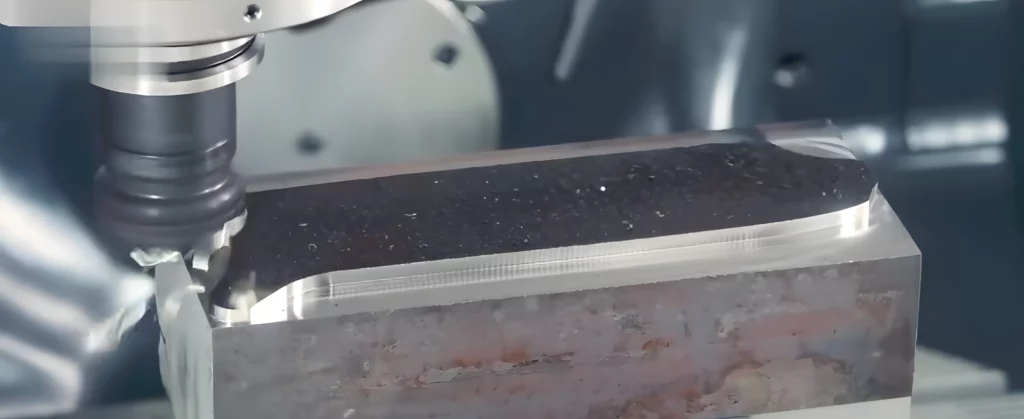

While titanium has many benefits, machining this material comes with different challenges. Precisely, titanium is hard to work with because of its unique properties. Now, let’s take a look at different properties that make this CNC-part machining difficult:

- Low Young’s Modulus: The stiffness of titanium metals is shown by their low Young’s Modulus. Because of this, titanium is more likely to spring back and chatter, which lowers the quality of the surface and causes problems with the final work.

- Stickiness and Work Hardening: Like aluminum, titanium tends to stick together. This, along with work hardening, causes long chips to form. Automating cutting titanium is hard because these chips tend to wrap around tools. Chips that stick to cutting edges, especially at the beginning or end of a cut, can cause the tool to chip.

- High Heat Generation and Limited Heat Conductivity: Titanium generates much heat because it is tough but doesn’t transfer heat very well. Titanium is different from other materials because it needs coolant instead of chips to remove heat before it harms cutting tools.

- Susceptibility to Work Hardening: Titanium is prone to work hardening, which happens most often when the heat control during cutting is not well handled.

- High Cutting Pressures: Titanium needs high cutting pressures, meaning cutters get strong shocks when they enter and leave cuts. Tools can chip too much if you don’t control these forces, especially when you go in or out.

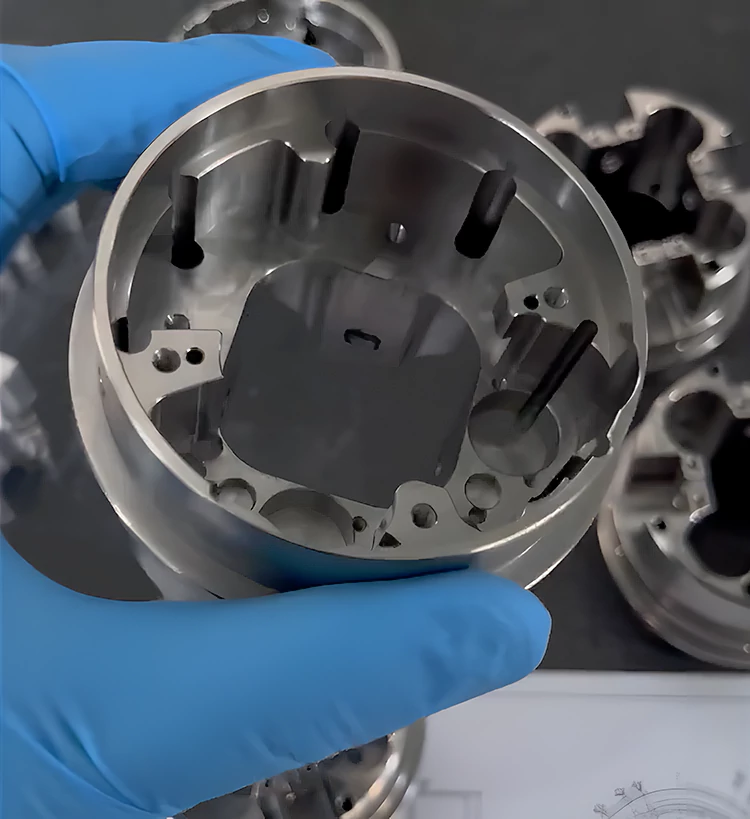

What Industries Use Titanium-Machined Parts?

As a commonly used production material, titanium is used for CNC-part machining for various industries. This includes:

- Aerospace: Titanium components have the highest demand in the aerospace industry. The most critical applications for titanium components rely on jet engines, airframe componentse spacecraft. Titanium is the ideal metal for aircraft manufacturing due to its low weight, high resistance to corrosion and high temperatures, and ability to sustain these temperatures.

- Automóvel: Most applications in the automotive industry include engine valves, exhaust systems, and suspension springs. When used in automotive applications, titanium components can lead to increases in horsepower and torque, as well as improvements in fuel economy. If you can believe it, titanium reduces the weight of the material by such a substantial amount that it enables industrial markets to truly achieve breakthroughs in production technology while simultaneously experiencing dramatic cost savings.

- Médico: Titanium has the remarkable capacity to form strong bonds with bone and live tissue, as discussed in the previous section. Because of this, it is an excellent choice for the construction of orthopedic implants.

- Shipbuilding: Titanium alloy did not become a viable choice for the production of ships and submarines until the 1960s, when its price experienced a major decline. However, today, titanium has a high corrosion resistance, even when exposed to salt water.

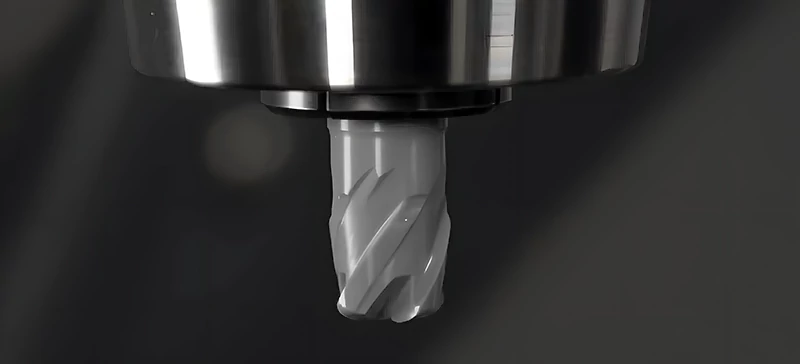

Choosing the Right Cutting Tools for Titanium

Choosing the right tools for cutting titanium is an important step that greatly affects how fast and well the process works. To get the best results from Maquinação CNC, we follow these six basic rules when picking tools made for titanium:

Choose Cutting Tools with More Flutes

Titanium’s unique qualities mean it must be worked with in a certain way. Using tools with more flutes, like a 10-flute end mill, is helpful because radial contacts and rpms need to be slowed down. By adding more flutes, the tool can engage more teeth in the cut, which reduces chatter, which is a typical problem with titanium because it is not as stiff.

Maintain a Sharp Cutting Edge and Avoid Interrupted Cuts

Because titanium is hard and flexible, keeping a sharp cutting edge is crucial. A sharp edge makes it easy to make chips without touching them. But it’s important to avoid irregular cuts, which could damage the tool’s sharpness and cause it to break before it should.

Opt for Appropriate Cutting Tool Coatings

Coatings are a key part of dealing with the strong heat when machining titanium. Titanium Aluminum Nitride (TiAlN) coatings are highly suggested because they work well with the temperatures used in machining and have extra lubrication, which keeps problems like built-up edge, galling, and chip welding from happening.

Titanium carbo-nitride (TiCN) e PVD diamond treatments are also good answers. On the other hand, you should avoid coatings made of ceramic and CBN because they are not good for titanium use.

Explore High-Feed Mills

High-feed milling is based on the idea that the tool should be engaged as much as possible while keeping axial and radial pressure as low as possible. These tools are good at exactly what is needed to machine titanium, which makes them a great choice for this material.

Select Appropriate Insert Shapes

Titanium is best machined with round inserts like toroidal or button cutters, but the insert’s form should match the application’s needs. Choose cuts with lead angles that help thin the chips. A 45-degree facemill is better than a 90-degree one.

Incorporate Secondary Relief

Secondary relief is an important part of making tools for cutting titanium. Ensuring that tools have strong support right behind the cutting edge strengthens them and lasts longer.

Boosting Titanium Machining Productivity: 5 Effective Strategies

Elevating productivity in titanium machining demands a strategic approach that accounts for the material’s unique characteristics. Implement these five proven tips to optimize your processes and achieve enhanced results:

- Adopt an “Arc In” Approach for Entry: A direct feed into the stock is insufficient when machining titanium. Instead, employ an “arc in” technique, guiding the tool softly into the material along a curved path. This gradual approach mitigates abrupt cutting forces and ensures a smoother transition by avoiding a straight-line entry.

- Enhance Axial Cuts with Strategic Adjustments: Efficient axial cuts demand strategic adjustments to counter potential challenges:

- Address pocket wall deflection by segmenting milling into axial stages. Maintain an incremental ratio of 8:1, ensuring each step’s axial cut is no more than eight times the wall’s thickness.

- To avoid oxidation and work hardening, change the axial depth of the cut for each pass, dispersing the problem area along the tool flute.

- Embrace Chamfer Edges for Smooth Transitions: Abrupt stops during machining can be detrimental. Prioritize creating chamfer edges before starting the application. This proactive step minimizes sudden transitions, enabling the tool to decrease its radial depth of cut as it concludes the process.

- Balance Cutting Speed and Feed Rate: Striking the right balance between cutting speed and feed rate is pivotal. Focus on maintaining high feed rates while adhering to machining best practices. Recognize that temperature variations are more influenced by cutting speed than feed rate. Prioritize keeping the feed rate elevated, as higher speed with carbide tools drastically impacts temperature.

- Leverage Ample Coolant Usage: Generously applying coolant serves two crucial purposes: dissipating heat from the cutting tool and effectively flushing away chips. This practice significantly reduces cutting forces and fosters optimal machining conditions.

Conclusão:

By putting these precisely crafted techniques into action, your approach to machining titanium will become more streamlined, efficient, and productive, resulting in superior CNC component production results.

If you have more questions, consult our professional CNC manufacturer at Prototool.