ツーショット射出成形:工業生産で知っておくべきこと

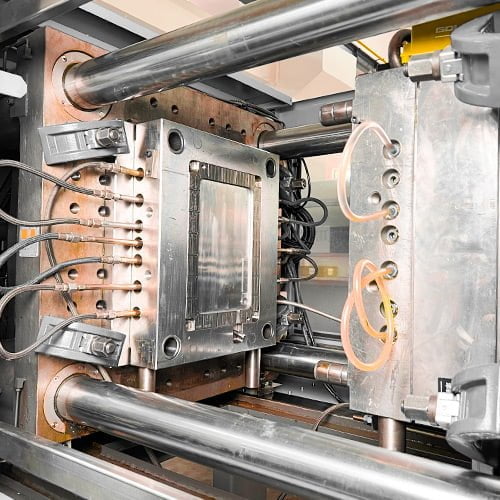

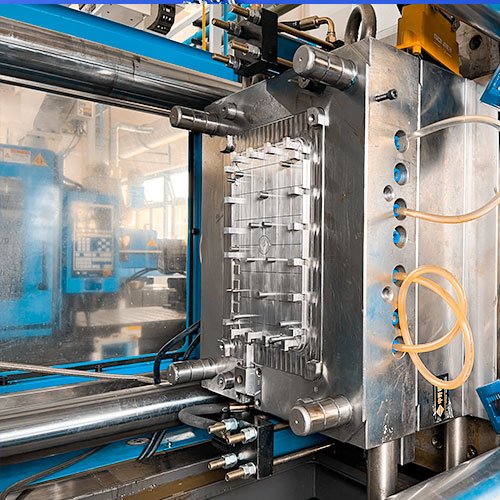

Since its inception, the plastic injection molding market has advanced significantly. It has advanced significantly in terms of productivity, cost-effectiveness, and new and creative approaches to product manufacturing. Two-shot injection molding is one of these creative methods. Multi-material injection molding, two-color injection molding, two-k injection molding, or double-shot injection molding are other names for this procedure. People inject two separate materials into the same mold to create the product in two-shot injection molding. These substances are administered sequentially rather than simultaneously. The product is not discharged from the mold between the two shoots but is produced in a single step. Because two-shot injection molding does not require several production stages, […]

プラスチック射出成形加工:最高のルーキーガイド

As complicated as it may appear to the average customer, plastic injection molding processing is a typical manufacturing technique used to make a wide range of commonplace objects. Various plastic injection molding companies like Prototool offer this service to assist in the manufacturing of plastic objects that have become a part of our daily lives, regardless of their complexity, craftsmanship, size, or dimensions. Now for anyone opting to invest in such a service without any know-how about plastic injection molding, this detailed guide will enlighten you with all the essential details. So without further ado, let’s dive into the details of this efficient manufacturing process. Process Characteristics The processing of […]

射出成形のコスト:計算方法とアドバイス

If you’re opting for the injection molding process for shaping and manufacturing plastic and rubber items for your business, you may be curious to know ‘what is the injection molding cost estimate’? Generally, when you’re opting for any manufacturing process, it’s evident that multiple stages/processes, materials, and additional requirements may need funding for the manufacturing process to proceed and complete. Whether it’s the simple manufacturing of wooden tables or plastic and rubber materials used in different industries like tech, hardware, etc., producing anything and everything is only possible if you can fund it. For instance, if we talk about making wooden tables, electricity costs, wood costs, base and structure cost […]

射出成形材料:一般的な種類と使用方法

プラスチック射出成形用の材料には、化学の授業で習ったような名前がついている。ポリプロピレンはポリテンと韻を踏んでおり、ポリスチレンと頭文字が似ている(PP)ことから、十分に難しい(PS)と言える。適切な射出成形材料を選ぶには、試作品と生産品の間で異なるかもしれない用途のニーズを知ることが特に重要です。考慮すべきことは数多くありますが、すべては基本的なことから始まります。射出成形材料を選択する前に、部品の目的とそれがさらされる物理的環境を考慮しなければなりません。その結果、あなたは明確に [...] [...]しなければならない。

透明射出成形プラスチックの完全ガイド

透明プラスチックの射出成形工場を訪れたとしよう。透明プラスチックの射出成形は、原料を溶かし、粘性のある液体を射出成形用金型に押し込み、冷やして固める。電化製品から家庭用品、自動車、食品包装に至るまで、ほとんどすべての製品に成形部品が使われている。射出成形は比較的簡単な作業のように見えますが、金型を作ることから材料の化学的・物理的特性を理解することまで、正しく行うには多くの科学的知識が必要です。このガイドでは、透明射出成形プラスチックのすべてを学びます。また、このガイドには [...] も含まれています。

Silicone injection molding: Everything You Need To Know

An injection molding manufacturing technique is used to create items out of thermoplastic and thermosetting materials. The process entails putting the material into a heated barrel, mixing it, and injecting it forcefully into a mold cavity using a reciprocating screw or a ram injector. The injection-molded object is then dried to conform to the shape of the mold cavity. When it comes to silicone injection molding, we have to talk about the invention of injection molding first. What Is Silicone Injection Molding? The invention of the injection molding method dates back to the late 1860s, when Phelan & Colander, a manufacturer of pool cues, offered a prize to anybody who […]

金属射出成形:学ぶべきことすべて

MIM技術の採用を計画している人は、「金属射出成形とは何か」を探求することに興味があるかもしれない。 現代技術であるMIMは、金属製造技術として理想的なソリューションである。さらにこの技術は、先進的で最新の金属製造工場や企業の間では比較的標準的なものである。 幸いなことに、MIMが提供する多くのユニークな機能と設計面により、MIMは、今日の高い要求と品質重視のテンポの速い業界の金属産業で使用できる理想的な金属製造機械として機能する。では、金属射出成形技術のガイドラインの詳細に飛び込んで、それがどのように機能し、何がそれを[...]させるのかについて、より正確な概要を説明しよう。

Injection Molding Process: The Most Complete Summary Of Pros & Cons

Plastic and plastic molding is one of the biggest industry sectors at this date and time. This industry works on developing different plastic parts with the help of different kinds of plastic materials to make new ones. The (plastic) injection molding process is one of the most commonly used processes in the plastic manufacturing industry to manufacture new parts and minimize waste production as much as possible. Here it is essential to note that the injection molding process has its own advantages and disadvantages, with the pros outweighing the cons in the end. It is a fast and time-saving process that results in a large quantity of plastic in a […]

SPI Mold classification: A Complete Introduction to The Standards&applications

The Society of Plastic Industry (SPI) designates 5 key standards for injection molding tooling. These standards help to guide the molding engineers to understand the suitability of the project for an injection molding process. It also helps to gazette the right type of mold to meet the client’s cost, quality, and production volume objectives. Today, there are 5 SPI mold classifications for mold tooling quality and capacity. These classifications help to understand the rigor of operations each mold is suitable for, the volume of parts that can be made from the mold, and the extent of quality that can be expected. Choosing a mold tooling standard relies heavily on the […]